Why Does Power Inverter Output Power Not Reach Rated Power

Jun 12, 2025 · Wondering why your inverter isn''t delivering full power? Learn the top reasons why power inverters fall short of rated output and how to fix them. Expert tips included!

Solis Seminar 【Episode 40】: Reasons for the low power

Feb 25, 2022 · 11.The inverter was turned on by mistake in the constant voltage mode, resulting in low operating power. Solution: For the inverter to turn on the constant voltage mode by

Inverter Generator Runs But No Power: Troubleshooting Tips

Dec 20, 2024 · Discover why your inverter generator runs but produces no power in this insightful article. We delve into common causes like fuel issues and electrical faults, offering practical

The Inverter Energy Yield is Low or No Power is Displayed

Jun 6, 2025 · 5.5.3 The Power Curve for Energy Management Decreases or Decreases to Zero on the Overview Page 5.5.4 The PV Terminal of the Inverter Has no Input Voltage (The PV

Understanding Low Frequency Power Inverters

6 days ago · Applications and Benefits: Why Use Low Frequency Power Inverters? Low frequency power inverters offer several benefits over their high frequency counterparts, including: –

How to Troubleshoot and Fix Common Inverter

6 days ago · Inverters are an essential part of many electrical systems, converting direct current (DC) to alternating current (AC). When an inverter malfunctions,

Power Inverter Troubleshooting – Common Problems and

Sep 24, 2024 · Common Power Inverter Problems and Solutions 1. Inverter Not Turning On If your power inverter fails to turn on, follow these troubleshooting steps: Check the battery

Inverter not Charging

Jul 29, 2024 · Is your inverter not charging? Discover common reasons like battery issues, wiring problems, and more in this comprehensive guide. Learn troubleshooting tips to restore power

A review on single-phase boost inverter technology for low power

Feb 1, 2024 · Solar Photovoltaic (SPV) inverters have made significant advancements across multiple domains, including the booming area of research in single-stage boosting inverter

The Inverter Energy Yield is Low or No Power is Displayed

Jun 6, 2025 · This document provides common troubleshooting cases for Huawei residential Smart PV solution and provides reference for engineers and users to handle common issues.

6. Troubleshooting and Support

Jun 17, 2025 · The Inverter can supply more power than the nominal power level for a short time. If the time is exceed the inverter stops. After three restarts followed by another overload within

Idle ''no load'' Consumption: Specs vs Your

Dec 10, 2019 · Dynamote Brutus 3200 watt 120v. low frequency iron core transformer 96 watts <88 watts> Brutus is an antique (1984-86??) being the very first high frequency electronics

6 FAQs about [The inverter has low power]

What is inverter low voltage?

Now that we know what inverter low voltage is, let's explore some common causes behind it. One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible cause could be an inadequate power source or improper electrical connections.

Why is my inverter low voltage?

Another possible cause could be an inadequate power source or improper electrical connections. Faulty wiring can also result in voltage fluctuations. If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health.

What are the most common inverter problems?

Whether you’re dealing with an inverter low battery problem, an inverter overload problem, or any other common issue, this guide will provide you with practical inverter solutions to keep your power backup system running smoothly. Let’s dive into the 15 most common inverter problems and solutions you might encounter:

Why is my inverter NOT working?

By understanding the causes behind such issues and following the appropriate diagnostics, you can get your inverter back to working optimally. Remember to check the battery health, power source, and electrical connections regularly to avoid potential voltage troubles in the future. Are you experiencing voltage troubles with your inverter?

How do I know if my inverter is low voltage?

If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health. Measure its voltage output using a multimeter to ensure it is within the recommended range. If the reading is below the recommended level, it's time to replace the battery.

What should I do if my inverter is not working?

Make sure to choose a battery that meets the specifications of your inverter. Secondly, ensure that your power source is sufficient to handle the load. Consider upgrading your power source or consult an electrician for further assistance. Lastly, double-check all electrical connections and replace any faulty wiring.

Learn More

- Low power 12v to 220v inverter

- The inverter has low power

- 12v inverter low power

- Assembly of high power industrial frequency inverter

- Which is better lithium battery plus inverter or mobile power supply

- New 20kw low voltage three-phase energy storage inverter

- Volt inverter high power

- How much power inverter is needed for 1450w

- Which inverter has both small power and large

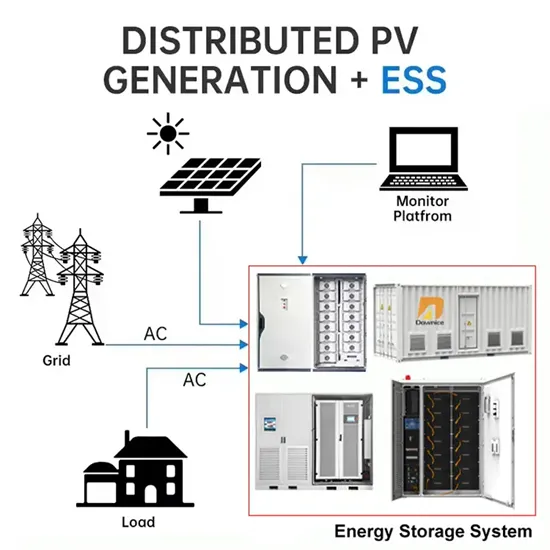

Industrial & Commercial Energy Storage Market Growth

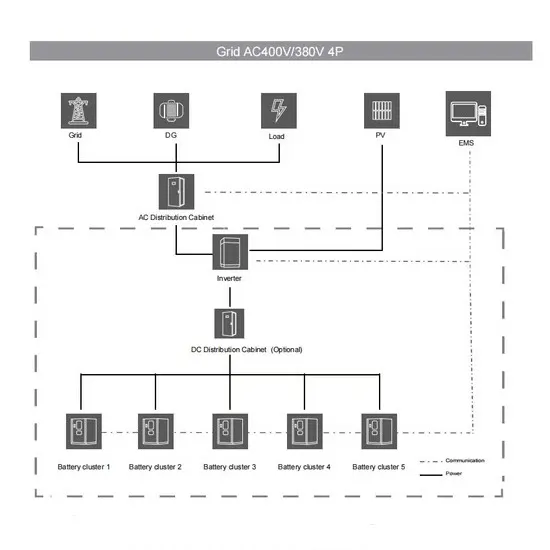

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

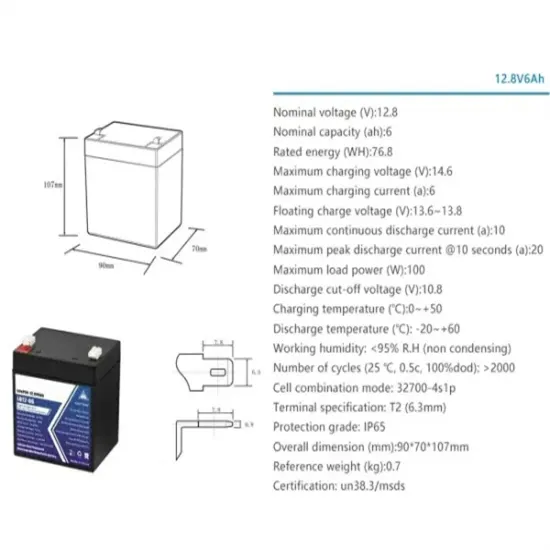

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.