Experimental and numerical study to optimize building

Apr 15, 2024 · The study addresses the issue of heat dissipation in Building Integrated Photovoltaic (BIPV) roofs by proposing a novel PV module and establishing its testbed in

Dimensions and specifications of monocrystalline

Dimensions and specifications of monocrystalline photovoltaic panels Monocrystalline solar panel dimensions & weight - 365 watt. Dimensions: 1776 mm × 1052mm × 35mm.Area =

Specifications and dimensions of engineering

Key specifications to focus on include power output, efficiency, dimensions, weight, voltage, current ratings, and certifications, all vital for planning and designing an efficient solar energy

Ventilation and heat dissipation analysis of photovoltaic roof

Jun 1, 2023 · The results show that, under the same conditions, when the spacing is 0 mm and 80 mm, the temperature of the backplane and the substrate of the PV module gradually

Heat Transfer Analysis of Ventilated Photovoltaic Wall Panels

Apr 4, 2025 · To reduce the temperature of photovoltaic wall panels and improve the photovoltaic conversion efficiency, this paper constructs a computational fluid dynamics (CFD) numerical

Photovoltaic power station panel specifications and

Page 1/3 Photovoltaic power station panel specifications and dimensions Systems can be designed to be 12, 24, or 48 volts. Panels, solar panel batteries, and inverters each come with

Dimensions and specifications of photovoltaic panel

Conclusion The first section of the datasheet usually contains the module specifications. The Module Specifications section of a solar module datasheet provides basic information about

Do solar photovoltaic panels need heat dissipation

The heating up of the solar panel during the photovoltaic conversion of solar irradiance into electricity leads to a faster rate of degradation and a decline in energy efficiency. According to

Advancements in cooling techniques for enhanced efficiency

Apr 1, 2025 · Abstract Solar photovoltaic (PV) cells have emerged as the primary technology for producing green electricity. This innovation harnesses direct sunlight to generate power and its

Experimental analysis of innovative perforated heat sinks for

Jan 1, 2025 · The proposed cooling solutions for the photovoltaic panels include four different types of heat sinks with fins. The experimental setup was placed on a roof terrace, exposing

Haier photovoltaic panel specifications and dimensions

Solar panels are designed to withstandvarious weather conditions,including hailstorms. Hail resistance can be indicated either by the resistance of the glass in Kilopascals (kPa) or by

Are heat dissipation photovoltaic panels good

Can photovoltaic panels reduce heat induced inefficiencies? The reduction of heat-induced inefficiencies in photovoltaic panelsnot only enhances energy output but also contributes to a

Price of heat dissipation photovoltaic panels

Heat pipe cooling with its high heat flux dissipation capability was shown to be effectivefor PV cooling," the research group said. The scientists said that PCMs are effective at absorbing

Specifications and dimensions of rooftop photovoltaic

Solar panels generate clean energy and significant savings, but they aren''''t a one-size-fits-all solution. The size and weight of solar panels vary depending on the make and model, with

Ventilation and heat dissipation analysis of photovoltaic roof

Jun 1, 2023 · As a green and clean energy, the utilization and development of solar energy have attracted much attention. Moreover, solar photovoltaic (PV) technology has been vigorously

Heat-dissipation performance of photovoltaic panels with a

Request PDF | On Sep 1, 2023, Fang Wang and others published Heat-dissipation performance of photovoltaic panels with a phase-change-material fin structure | Find, read and cite all the

Heat Transfer Analysis of Ventilated Photovoltaic Wall Panels

Apr 4, 2025 · Photovoltaic (PV) wall panels are an integral part of Building-Integrated Photovoltaics (BIPV) and have great potential for development. However, inadequate heat

Dimensions and specifications of photovoltaic panels

What are the characteristics of a solar panel? Solar Panel Structure: The solar panel dimension, composition, and photovoltaic (PV) technology. Average Solar Panel Size: Available roof

Design and performance assessment of a solar photovoltaic

Oct 20, 2024 · This study investigates the effectiveness of an indirect passive cooling solution for photovoltaic (PV) panels using flattened heat pipes (FHPs) and phase change material (PCM).

Enhancement of photovoltaic module performance using

Sep 1, 2023 · The primary application of solar energy is in the generation of electricity through photovoltaic (PV) systems. Solar panels with photovoltaic cells convert sunlight directly into

Advancing photovoltaic thermal module efficiency through optimized heat

Jul 15, 2025 · Nevertheless, photovoltaic panels generate superfluous thermal energy during electricity production, which elevates temperature and diminishes the efficiency of photovoltaic

Heat transfer photovoltaic panel of dimension

The convective heat transfer between wind and photovoltaic (PV) panels will cause 8 fluctuations in the temperature and performance of PV cells, which have a great negative impact on 9 the

Photovoltaic panel cooling using ground source energy: CFD

Jun 1, 2024 · Passive cooling relies on natural heat dissipation mechanisms such as convection, radiation, and conduction to remove excess heat from the panels. Active cooling utilizes

6 FAQs about [Specifications and dimensions of heat dissipation photovoltaic panels]

What are solar panel datasheet specifications?

Key Takeaways of Solar Panel Datasheet Specifications Solar panel datasheet specifications include factors such as power output, efficiency, voltage, current, and temperature coefficient, which determine the performance and suitability of the panel for specific applications.

Which PV wall panels have the best heat dissipation effect?

Among them, the arc-ribbed cavity structure PV wall panels have the best heat dissipation effect. Further studies have shown that the curvature, rib height, width, and spacing of the curved ribs significantly affect the heat dissipation performance of the photovoltaic panels.

What is the environmental temperature of photovoltaic panels?

The study sets the environmental temperature at 25°C and analyzes the temperature of the two types of photovoltaic panels under solar radiation strengths of 400 W/m 2, 600 W/m 2, 800 W/m 2, and 1000 W/m 2. Figure 23. Schematic diagram of cavity structure of ventilated photovoltaic wall panels.

What is the average surface temperature of PV wall panels?

The average surface temperatures of flat-plate, rectangular-ribbed, and arc-ribbed cavity structure PV wall panels were 59.42 °C, 57.56 °C, and 55.39 °C, respectively, under natural ventilation conditions. Among them, the arc-ribbed cavity structure PV wall panels have the best heat dissipation effect.

Can water cooled PV panels improve heat dissipation?

In addition, while water-cooled photovoltaic panels can improve heat dissipation, they are expensive to maintain and risk leakage. Mechanical ventilation, though more effective, poses challenges for practical implementation in engineering applications. In real projects, air-cooled channels have been integrated into PV systems.

What is an example of a solar panel datasheet?

An example of a solar panel datasheet composed of wafer-type PV cells is shown in Figure 1. Notice that the datasheet is divided into several sections: electrical data, mechanical data, I-V curve, tested operating conditions, warranties and certifications, and mechanical dimensions.

Learn More

- Specifications and dimensions of photovoltaic panels for water pumps in Sao Tome and Principe

- Specifications of photovoltaic crystalline silicon panels

- There are several models and specifications of photovoltaic panels

- What are the specifications of flexible photovoltaic panels

- Photovoltaic panels in various specifications

- Yemen 3v photovoltaic panel specifications and dimensions

- How many specifications and models of photovoltaic panels are there

- Will photovoltaic panels generate heat in summer

- Solar Photovoltaic System Specifications and Dimensions

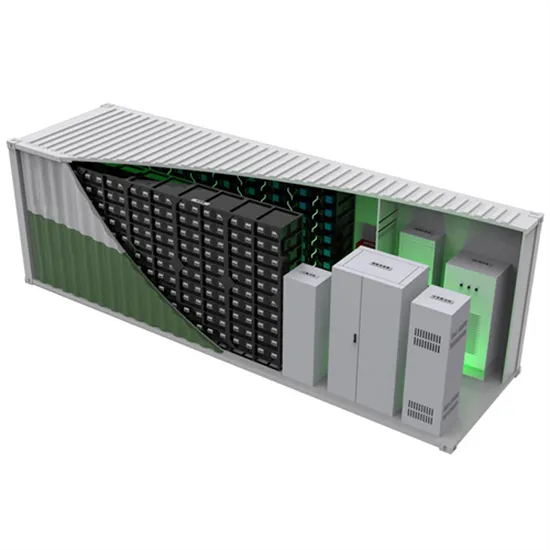

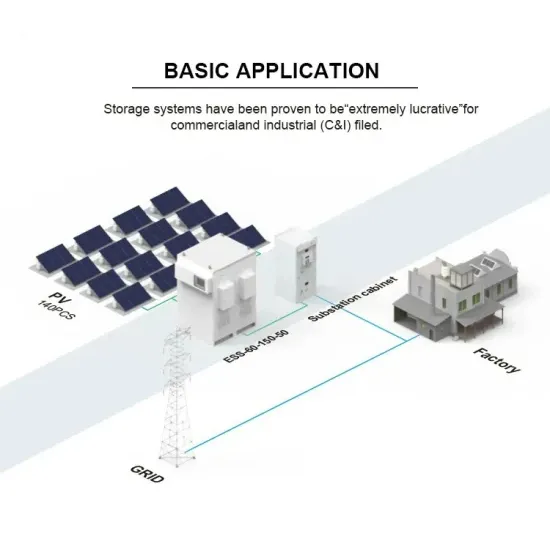

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.