Sensitivity analysis for photovoltaic water pumping systems: Energetic

Mar 1, 2017 · The economic analysis for these water pumping systems showed that photovoltaic- batteries/Pump system is the optimum solution in the three countries.

Solar PV based Drinking Water Pumping Systems

A Case Study of Solar PV based Drinking Water Systems Mokhada taluka acquires adequate rainfall but due to hilly terrain and lack of water recharge systems, several habitations of the

Standard, Specification & Benchmark Cost | MINISTRY OF

Specifications for Solar Street Lights and Solar Study Lamps – specifying minimum performance parameters for batteries (581 KB, PDF) Updated Specification and Testing procedure for the

Photovoltaic panel water tank specifications

Is solar photovoltaic water pumping system feasible? ing area of research for more than 50 years. In the early 70s, efforts and studies were undertaken to explore the possibility of SPVWPS as

Analysis of specifications of solar photovoltaic panels

May 1, 2022 · The use of photovoltaic power plants is rapidly expanding, despite the continued growth in the production of traditional mineral resources. This paper analyses photovoltaic

DESIGN AND IMPLEMENTATION OF FLOATING SOLAR

Jul 15, 2022 · Abstract: Floating solar power plant is an innovative approach of using photovoltaic modules on water infrastructures to conserve the land along with increase in efficiency of the

Solar photovoltaic panel specifications dimensions and

Specifications of the solar panel include details on the efficiency, wattage, temperature coefficients, and warranty. On the basis of the solar panel manufacturers and solar panel

Ministry of New and Renewable Energy Jawaharlal

Oct 16, 2012 · I. DEFINITION A solar photovoltaic (SPV) water pumping system consists of a PV array, a DC/AC surface mounted/ submersible/ floating motor pump set, electronics, if any,

Design of Solar Power Based Water Pumping System

Mar 8, 2022 · AA solar water pumping system is designed with solar photovoltaic panels and locally available electric pumps. All components in the system design have been procured

SPECIFICATION FOR SOLAR PHOTOVOLTAIC WATER

Dec 31, 2022 · 1. SCOPE These specification covers design qualifications and performance specifications for Centrifugal Solar Photo Voltaic (SPV) Water Pumping Systems from 1HP

Specifications of Photovoltaic Pumping Systems in Agriculture

Abstract Autonomous photovoltaic (PV) installation is a promising solution to supply water pumping systems, used for crop irrigation in remote agriculture areas, which are characterized

443-23-ARTAL_ICREPQ23-Photovoltaic_Water_Pumping_

Jun 19, 2023 · 1. Introduction In this decade, solar photovoltaic water pumping systems are being studied as a viable and economical option. Some studies indicate that photovoltaic water

Photovoltaic (PV) Panel Technical Specifications | The Sun Pays

Photovoltaic (PV) panels are the core of any solar power system. Understanding key specifications will help you compare quality, performance, and long-term reliability across

Specifications of Photovoltaic Pumping Systems in Agriculture

Sizing Optimization of the Photovoltaic Irrigation Plant Components Abstract Sizing PV water pumping plants is an essential step for the system design and use, since it affects the

Specifications of Photovoltaic Pumping Systems in Agriculture

Sizing PV water pumping plants is an essential step for the system design and use, since it affects the installation autonomy, the safe operation, and cost of the system. Thus, in this chapter, a

Design of Photovoltaic (PV) Pumping

Overview In order to implement cost effective photovoltaic (PV) pumping system, it is necessary to follow some basic guidelines to design and size every system component. This page will

A Review On Design And Performance Analysis Of Solar

May 22, 2025 · Abstract This research aims to enhance the performance and reliability of Solar Photovoltaic Water Pumping Systems (SPVWPS) to promote their wider adoption in rural and

Floating photovoltaic panel specifications and dimensions

The benefits of floating PV panels on water bodies soon attracted interests in the energy sector and a number of demonstration and commercial projects have been realised

Specifications and dimensions of engineering

Key specifications to focus on include power output, efficiency, dimensions, weight, voltage, current ratings, and certifications, all vital for planning and designing an efficient solar energy

Specifications and dimensions of rooftop photovoltaic

Solar panels generate clean energy and significant savings, but they aren''''t a one-size-fits-all solution. The size and weight of solar panels vary depending on the make and model, with

APPENDIX 2 TECHNICAL SPECIFICATIONS FOR SOLAR

May 31, 2024 · Solar-PV System Specifications This section covers the specification of works for the abstraction of water from the source using solar energy related equipment here collectively

Solar PV powered water pumping system – A review

Jan 1, 2021 · Economic and environmental aspects were also discussed. Solar PV water pumping system is found to be more economical, eco-friendly, reliable, with less maintenance and a

Ministry of New and Renewable Energy Jawaharlal

Oct 16, 2012 · PERFORMANCE SPECIFICATIONS AND REQUIREMENTS (DUTY CYCLE) The Solar PV Water Pumping System should provide a minimum of 85 liters of water per watt peak

6 FAQs about [Specifications and dimensions of photovoltaic panels for water pumps in Sao Tome and Principe]

How do you design a solar water pumping system?

When designing a solar pumping system, the designer must match the individual components together. A solar water pumping system consists of three major components: the solar array, pump controller and electric water pump (motor and pump) as shown in Figure 1.

What are the components of a solar water pumping system?

A solar water pumping system consists of three major components: the solar array, pump controller and electric water pump (motor and pump) as shown in Figure 1. Note: Motor and pump are typically directly connected by one shaft and viewed as one unit, however occasionally belts or gears may be used to interconnect the two shafts.

How to maintain solar photovoltaic water pumping system?

f a y, could be taken well in advance to save any equipment from damage.iv.Normal and preventive maintenance of the Solar Photovoltaic Water pumping systems such as cleaning of module surface, tightening of all electrical connections, changing of tilt angle of module mounting structure, cleaning & greasing of motor pump sets, changing filters etc

What are the characteristics of solar pump?

Normally a solar pump can operate on wide range of water flow rate in response to variation of solar radiation. Generally there are three kinds of pump normally used as solar pump: Here is the table that explain the different characteristic of solar pump :

What size water pipe should a solar water pumping system use?

The designer should initially use pipe that is the same size as the inlets and outlets. The designer then undertakes the frictional loss calculations for that size of water pipes using the known maximum water flow for that solar water pumping system.

What data should be included in a solar water pump design?

The specific data would be the size of the inlet and outlet that the water pipe would be connected to. Figure 14 a, b and c shows key dimensions of the three water pumps shown in Figure 13 and used in the solar water pumping systems used in Table 7. The designer should initially use pipe that is the same size as the inlets and outlets.

Learn More

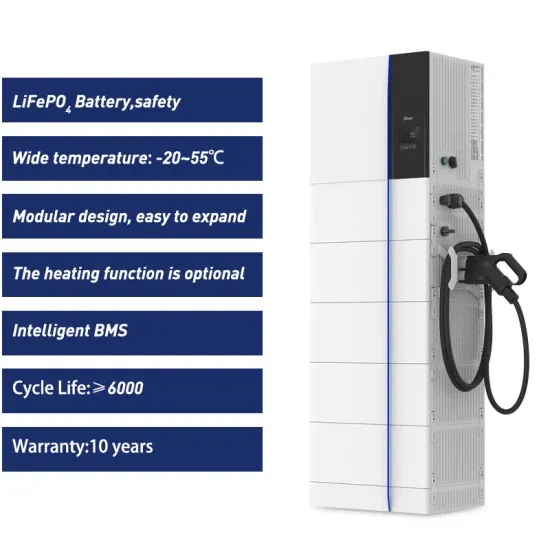

- BESS price of photovoltaic panels in Sao Tome and Principe

- Maintenance contract for photovoltaic base stations in Sao Tome and Principe

- Sao Tome and Principe Photovoltaic Glass

- Which glass photovoltaic power generation company is the best in Sao Tome and Principe

- Sao Tome and Principe Hydrogen Energy Photovoltaic Site 100KWh

- Sao Tome and Principe Energy Storage Charging Station

- Sao Tome and Principe medical equipment lithium battery pack

- Specifications of photovoltaic panels 440M

- Photovoltaic panels in various specifications

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.