Battery configuration dependence to power line communication

Feb 15, 2024 · To mitigate these disadvantages in BEVs, the established literature demonstrates improvements to energy storage systems, such as fast charging techniques, improved battery

The Complete Guide to Li-ion Battery Pack Communication

Jun 16, 2025 · This article takes you deep into the communication world of battery packs, revealing how batteries "communicate" with devices in different scenarios and how to choose

What is the communication protocol of a 10S Lithium Battery

In a 10S Lithium Battery BMS, CAN can be used to communicate with other components in an electric vehicle (EV) or a stationary energy storage system. For example, the BMS can send

A non-academic perspective on the future of lithium-based

Jan 26, 2023 · In the field of lithium-based batteries, there is often a divide between academic research and industrial needs. Here, the authors present a view on applied research to help

Evaluation of an in situ QAM‐based Power Line

Aug 4, 2022 · This model is used to determine the effectiveness and optimal properties of PLC with QAM, as a means of in situ battery communication for Battery Electric Vehicles (BEVs) in

CAN Bus Protocol for Battery Communications

Jun 8, 2023 · Each battery cannot send this data to the inverter individually and must instead communicate to some form of aggregator responsible for combining and managing all the

An effective passive cell balancing technique for lithium-ion battery

Jul 1, 2025 · Battery management systems (BMSs) play a pivotal role in monitoring and controlling the operation of lithium-ion battery packs to ensure optimal performance and safety. Among

CAN Bus: Battery Management and Communications System

Dec 8, 2023 · Documentation on BMU(Battery Monitoring Unit) Communication Protocol installed in Li-ion Battery Pack and Settings. The new protocol, referred to as the "NEW version" is

Thermal fault detection of lithium-ion battery packs through

Apr 28, 2025 · Mina Naguib and colleagues propose an integrated physicsand machine-learning-based method for early thermal fault detection in battery packs. This approach enhances

Communication Protocol Reference Guide

Sep 12, 2023 · The Nuvation BMSTM is an enterprise-grade battery management system with support for various external communication protocols like Modbus RTU, Modbus TCP, and

Lithium battery BMS communication

Jun 2, 2025 · The communication between a Battery Management System and inverter is not merely an ancillary function; it is a central pillar of efficient energy management in lithium

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · How to Connect Lithium Batteries in Parallel Safely? In order to prevent potential hazards and optimize battery performance, it is necessary to

The Complete Guide to Li-ion Battery Pack Communication:

Battery pack communication involves sensitive data (such as battery status and user information) and critical control commands, making security a top priority. Encryption technologies,

Protocol for Lithium Battery Pack Modbus Protocol

Nov 21, 2023 · The master node is the host in the communication process. The information exchange is done by a question-and-answer method. The information and parameters of the

6 FAQs about [Lithium battery pack communication]

What is a passive cell balancing system for lithium-ion battery packs?

The presented research actually proposes a novel passive cell balancing system for lithium-ion battery packs. It is the process of ramping down the SOC of the cells to the lowest SOC of the cell, which is present in the group or pack. In simple words, consider a family having 5 members, such as parents and children’s.

Are lithium-ion batteries a viable energy storage solution for EVs?

The rapid growth of electric vehicles (EVs) in recent years has underscored the critical role of battery technology in the advancement of sustainable transportation. Lithium-ion batteries have emerged as the predominant energy storage solution for EVs due to their high energy density, long cyclic life, and relatively low self-discharge rates.

Why is performance evaluation important in lithium-ion batteries?

The study explores performance evaluation under diverse conditions, considering factors such as system capacity retention, energy efficiency, and overall reliability. Safety and thermal management considerations play a crucial role in the implementation, ensuring the longevity and stability of the lithium-ion battery pack.

What is battery management system?

The battery management system monitors aspects of the battery like the voltage, current, state of charge (SOC), state of health (SOH), travel range offered by the battery, battery temperature, and a host of other parameters. 2.

Can a PI controller regulate voltage differentials in lithium-ion battery packs?

The presented research actually proposes a novel passive cell balancing system for lithium-ion battery packs, leveraging a PI controller to regulate voltage differentials among the cells. The presented method is first simulated in MATLAB and then practically implemented to validate the results.

How can a battery management system improve battery life?

The presented method allows the BMS to maintain cell balance efficiently and prevent overcharging or discharging of specific cells, which can lead to reduced battery life or safety hazards.

Learn More

- Communication lithium battery pack

- Lithium battery pack communication

- Albania Power Lithium Battery Pack

- Lithium battery energy storage for communication base stations

- Kuwait low temperature lithium battery pack manufacturer

- No 9 lithium battery pack

- Lithium battery PACK new nickel sheet

- Democratic Republic of Congo Electric Stacker Lithium Battery Pack

- Lithium battery pack split charging

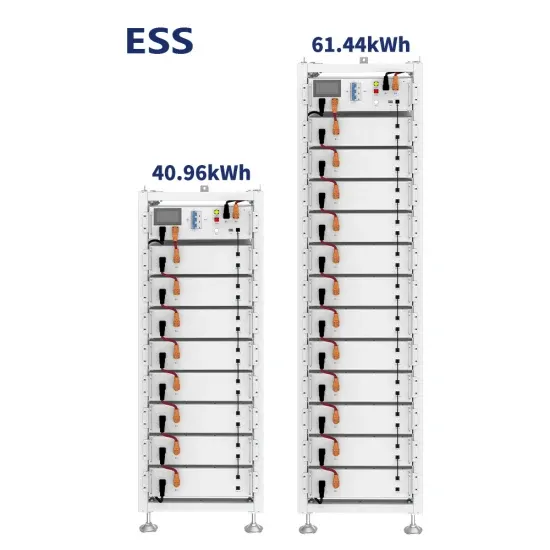

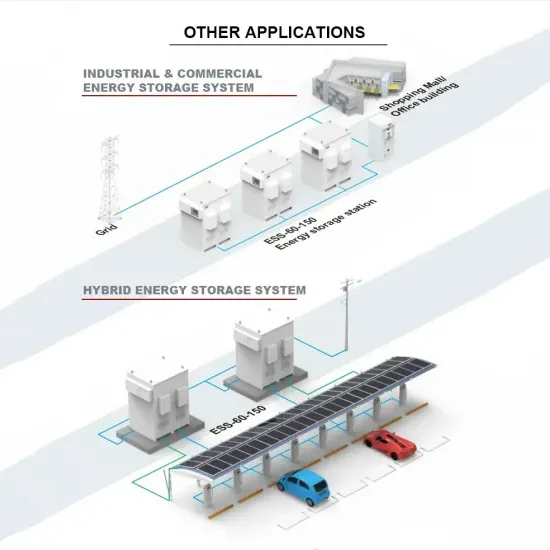

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.