What is Combiner Box

2 days ago · A combiner box, also known as a junction box, is a crucial electrical enclosure widely applied in photovoltaic (PV) systems, electrical power distribution networks, and diverse

智能分布式汇流箱 | Application

我们的高效分布式汇流产品 我们的高性能STM32微控制器、灵活的多协议电力线通信 (PLM)、无线连接解决方案、以及用于电流和电压测量的电能计量集成电路和高精度运算放大器可以帮助

PV String Combiners > Solar Combiner Boxes > EcoDirect

A PV combiner box is an electrical distribution box where DC breakers are housed. Its main purpose is to combine multiple DC inputs from the panels in the system into a single DC output.

什么是直流光伏太阳能汇流箱

太阳能汇流箱是指用户可以将一定数量的相同规格的光伏电池串联起来,形成单个的光伏串,然后将多个串并联成一个太阳能汇流箱。汇聚到太阳能汇流箱内

How does a Solar Combiner Box work

May 29, 2025 · What is a Solar Combiner Box? A solar combiner box is a crucial component in solar power systems. It combines the outputs from multiple strings of solar panels into a single

What is a solar combiner box and why is it used

Mar 25, 2025 · Learn all about solar combiner boxes. Combiner boxes combine solar strings into a single power source for inverters, limiting energy loss and

Photovoltaic Combiner Boxes

Aug 18, 2025 · The XLR8-CB Photovoltaic Combiner Box is intended for Solar installations where grid-tie in is required, combining output strings from multiple PV arrays. We offer both a steel

Solar Combiner Boxes – RAND Manufacturing Group – Solar

RAND PV Solar Combiner Boxes redefine the standard of solar technology by offering customized, innovative, and safety-conscious solutions for your specific solar installation''s needs.

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · What Is a Combiner Box? A combiner box, also known as a PV combiner box or solar combiner box, is an electrical enclosure that consolidates multiple strings of solar panels

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · As solar energy adoption continues to rise, the demand for efficient and reliable photovoltaic (PV) system components becomes increasingly important. Among these, the

6 FAQs about [Eritrea Photovoltaic Combiner Box]

What is a solar combination box?

A Solar Combiner Box is an essential electrical device used in photovoltaic (PV) power generation systems. Its primary function is to combine the output currents of multiple solar panel strings (PV strings) into a single output, which is then sent to the inverter for DC to AC conversion.

What is a photovoltaic AC combiner box?

The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC output side of the inverter and the grid connection point/load. It is internally equipped with input circuit breakers, output circuit breakers, and AC lightning arresters.

What is a solar combiner box & junction box?

A solar combiner box and a junction box serve distinct purposes in a photovoltaic system. The combiner box consolidates electrical outputs from multiple solar panel strings into a single output. It includes protective components like fuses, circuit breakers, and surge protection devices.

Do I need a solar combiner box?

Combiner boxes are required when there are more than three solar strings that need to be connected to the inverter. When working with less than three solar strings, they can be connected directly to the inverter without additional devices. For small residential solar systems with one or two strings, a solar combiner box is not a strict requirement.

How does a solar combiner box work?

If every string were wired directly to the inverter, it would result in complex cabling, higher costs, and increased risk of electrical faults. The solar combiner box solves this problem by consolidating the current from all strings into one streamlined output.

What are the different types of solar combiner boxes?

Most solar combiner boxes come in outdoor enclosures with minimum NEMA 3R rating, although NEMA 4 steel and NEMA 4X non-metallic enclosures are more common. These are the most common type, designed to combine multiple DC inputs from a solar array into a single output.

Learn More

- Photovoltaic combiner box heating

- Can the photovoltaic grid-connected combiner box be opened

- Universal standard photovoltaic combiner box

- Six-input and one-output photovoltaic combiner box

- Somaliland 9-input 1-output photovoltaic combiner box

- Photovoltaic primary combiner box

- 1000v photovoltaic combiner box

- Photovoltaic combiner box module

- Georgetown Photovoltaic Smart Combiner Box

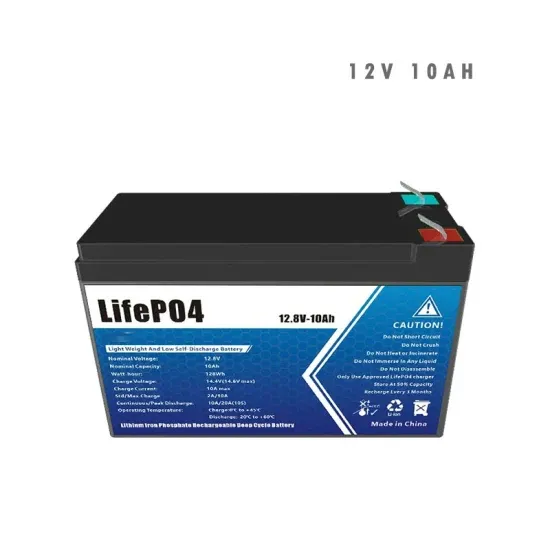

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.