What Is a Combiner Box as Used in PV System

Jun 9, 2025 · In a PV system, the combiner box is more than just an enclosure; it is a vital component that ensures safety, streamlines wiring, and supports the overall performance of

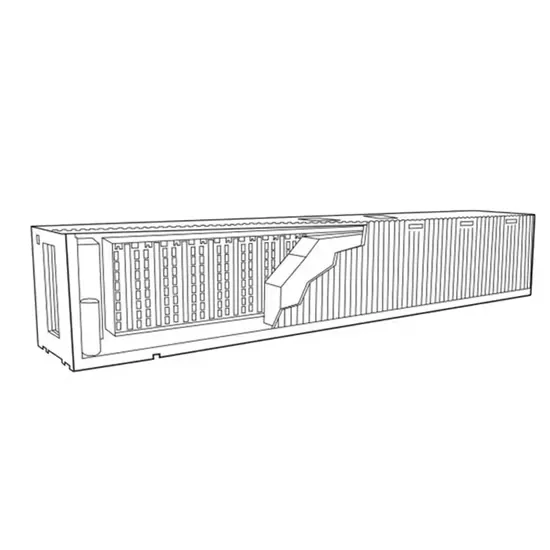

Low-temperature heating system, combiner box, and photovoltaic

A heating system and photovoltaic power supply technology, which is applied to auxiliary controllers with auxiliary heating devices, and temperature control using electric methods, can

PV Combiner Box: Complete Guide to Components

Apr 15, 2025 · PV Combiner Box (PV Combiner Box) is the key electrical equipment of solar power generation system, mainly used for centralized direct current of photovoltaic series, and

Weidmuller 3 String Combiner Box For Pholovoltaic Solar Heating

Weidmuller 3 String Combiner Box For Pholovoltaic Solar Heating SKU: T0003563 If this product is purchased and no stock is available, our team will contact you with the option of a full refund

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · A combiner box, also known as a PV combiner box or solar combiner box, is an electrical enclosure that consolidates multiple strings of solar panels into a single output.

UL44 Photovoltaic Cables: A Comprehensive Guide For PV

13 hours ago · Section 4: Cable Applications Across PV System Stages 1. Solar Modules → Combiner Box Common Cables: USE-2, PV Wire, RHW-2 Features: Sunlight resistance, high

What is a solar combiner box and why is it used

Mar 25, 2025 · Learn all about solar combiner boxes. Combiner boxes combine solar strings into a single power source for inverters, limiting energy loss and

PV Combiner Box: Ultimate Guide 2025 & ETEK Solar Solutions

4 days ago · What Is a PV Combiner Box? A solar combiner box (or photovoltaic combiner box) consolidates multiple strings of solar panels into a single main output circuit. It acts as the

Comprehensive Analysis Of UL44 Series Cables in PV Projects

13 hours ago · This article systematically analyzes the cable requirements of each PV station stage - from modules → combiner box → inverter → distribution → grid interconnection - and

6 FAQs about [Photovoltaic combiner box heating]

What is a photovoltaic AC combiner box?

The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC output side of the inverter and the grid connection point/load. It is internally equipped with input circuit breakers, output circuit breakers, and AC lightning arresters.

What is a solar combiner box?

Solar combiner boxes are essential components in solar photovoltaic (PV) systems, designed to consolidate the outputs of multiple solar panel strings into a single output for connection to an inverter. There are various types of combiner boxes tailored to meet specific needs and configurations in solar installations. Here are the primary types:

What is a PV combiner box?

A PV combiner box is an essential component in any solar system and there are several parameters kindly remember there are a few parameters which need to be checked in order for it to suit your solar structure. Here’s a useful guide to help you out: System Compatibility: First thing first, check how many solar panel strings your system has.

How do combiner boxes improve solar energy production?

Careful operational management can drastically increase reliability and efficiency for PV systems; furthermore, as photovoltaic technology develops, combined boxes will continue to innovate and upgrade themselves for reliable solar energy production. Explore the functions and operational management of PV combiner boxes in solar power systems.

How do you manage a photovoltaic combiner box?

Effective operational management is crucial to the performance and longevity of photovoltaic (PV) combiner boxes. Here is an outline of essential aspects of maintenance and management that ensure these systems operate efficiently and reliably. 1. Regular Inspection and Maintenance Services

Do you need a solar combiner box?

Adaptability: While smaller residential systems may not require a combiner box if they have only one to three strings, larger systems—ranging from four strings up to thousands—benefit greatly from their use. This adaptability makes combiner boxes suitable for both residential and commercial applications. II. Basics of PV Solar Combiner Boxes

Learn More

- Photovoltaic combiner box power supply

- Southern Europe Energy Storage Photovoltaic Combiner Box

- Photovoltaic combiner box current discrete rate

- Universal standard photovoltaic combiner box

- DC combiner box in photovoltaic system

- Nicosia Photovoltaic Combiner Box Wholesale

- Burundi 1500vdc photovoltaic combiner box

- Photovoltaic power station combiner box

- Three-phase photovoltaic combiner box

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.