What Does a Solar Combiner Box Do? Complete

Jun 24, 2025 · Bottom Line Up Front: A solar combiner box consolidates multiple solar panel strings into a single output before sending power to the inverter. It

What is a Combiner Box as Used in PV System

May 23, 2025 · In short, a solar combiner box is a centralized unit designed to collect, protect, and route solar-generated DC electricity efficiently and safely,

How to Choose the Best Solar Combiner Box for

Apr 27, 2025 · Looking for the best solar combiner box for your solar installation? Learn about different types of combiner boxes, including their components like

APPLICATION NOTE DC COMBINER BOX IN

Jul 25, 2025 · DC COMBINER BOX IN PHOTOVOLTAIC PLANTS IEC/UL Utility scale Protect and optimize your solar power plant with ABB solutions for DC combiner boxes. Simplify

PV DC Combiner Box

Jul 25, 2025 · A PV DC Combiner Box is a critical electrical enclosure used in photovoltaic (PV) power generation systems. It is strategically positioned between the solar PV array (multiple

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · Basic DC Combiner Box: Suitable for small to medium installations; provides essential string consolidation and protection. Smart Combiner Box: Includes monitoring

Combiner box connection for centralized string inverters

The DC combiner box is available in an IEC 61439-2-compliant design for DC system voltages up to 1,500 V with 20 to 30 A fuses, integrated surge protection, a flexible number of DC inputs

Ensuring Safety and Reliability: The Significance

Sep 22, 2023 · DC combiner boxes play an indispensable role in PV systems, providing critical safeguards for system installation and operation. As a leading

What is a PV combiner box and why we need it in solar systems

3 days ago · What Is a PV Combiner Box? A PV combiner box, also known as a solar combiner box or DC combiner box, is an electrical enclosure that consolidates the output from multiple

6 FAQs about [DC combiner box in photovoltaic system]

What is a combiner box in a photovoltaic system?

In a photovoltaic system, a combiner box acts as a central hub that consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring structure, enhance system security and simplify maintenance procedures.

What is a solar combination box?

A Solar Combiner Box is an essential electrical device used in photovoltaic (PV) power generation systems. Its primary function is to combine the output currents of multiple solar panel strings (PV strings) into a single output, which is then sent to the inverter for DC to AC conversion.

How do you manage a photovoltaic combiner box?

Effective operational management is crucial to the performance and longevity of photovoltaic (PV) combiner boxes. Here is an outline of essential aspects of maintenance and management that ensure these systems operate efficiently and reliably. 1. Regular Inspection and Maintenance Services

What is a solar combiner box & junction box?

A solar combiner box and a junction box serve distinct purposes in a photovoltaic system. The combiner box consolidates electrical outputs from multiple solar panel strings into a single output. It includes protective components like fuses, circuit breakers, and surge protection devices.

How do I choose a solar combiner box?

Investing in certified equipment ensures peace of mind and long-term reliability for your solar system. Compatibility with system components is another critical factor when selecting a solar combiner box. The box must integrate seamlessly with your photovoltaic system to ensure optimal performance and reliability.

How do combiner boxes improve solar energy production?

Careful operational management can drastically increase reliability and efficiency for PV systems; furthermore, as photovoltaic technology develops, combined boxes will continue to innovate and upgrade themselves for reliable solar energy production. Explore the functions and operational management of PV combiner boxes in solar power systems.

Learn More

- Photovoltaic combiner box DC cabinet

- DC combiner box in photovoltaic system

- Tunisia Photovoltaic DC Combiner Box

- Danish 1500vdc photovoltaic combiner box

- Africa Photovoltaic Combiner Box Wholesale Factory

- Six-input and one-output photovoltaic combiner box

- The role of the Peruvian photovoltaic combiner box

- Photovoltaic combiner box power supply

- Universal standard photovoltaic combiner box

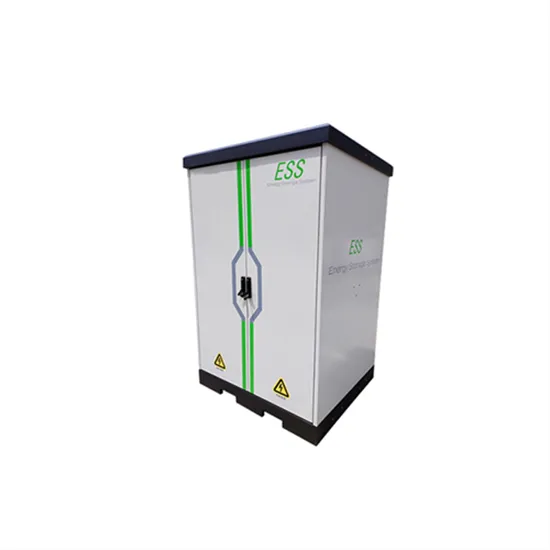

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.