Install combiner box for photovoltaic grid-connected

Wall-mounted or column-mounted installationsare recommended,ensuring the wall or column can support the combiner box''s weight. Install the combiner box''s support braces on the same

Photovoltaic power generation grid-connected combiner box

What is a photovoltaic AC combiner box? The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC

APPLICATION NOTE DC COMBINER BOX IN

Jul 25, 2025 · DC COMBINER BOX IN PHOTOVOLTAIC PLANTS IEC/UL Utility scale Protect and optimize your solar power plant with ABB solutions for DC combiner boxes. Simplify

Photovoltaic combiner box selection

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

Photovoltaic combiner box and grid-connected box

Photovoltaic combiner grid-connected box box and What is a combiner box in a photovoltaic system? ct current (DC) output of multiple solar panels. Its main purpose is to simplify the

Connection between photovoltaic grid-connected

A: A PV converter box is mainly used to collect the output current from PV cells, while a PV inverter (including grid-connected or off-grid PV inverters) converts the DC power generated

Connection between photovoltaic grid-connected

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

PHOTOVOLTAIC AC COMBINER BOX DETAILED EXPLANATION

What is a photovoltaic AC combiner box? The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC

Grid-connected photovoltaic power generation system

Grid-connected photovoltaic power generation system combiner box Can solar combiner boxes be integrated with smart grid technology? The integration of solar combiner boxes with smart

Introduction of combiner box-Shanghai IPKIS Power

Jun 9, 2022 · The combiner box is a wiring device that ensures the orderly connection and confluence function of photovoltaic modules in the photovoltaic power generation system. The

Photovoltaic grid connection through combiner box

The PV Next Fireman Switch automatically disconnects PV modules from the grid in case of fire. Simple and space-saving installation Learn more about our PV combiner boxes, surge

Understanding the Function of a Combiner Box in Solar Photovoltaic

May 10, 2024 · These codes dictate the proper sizing, rating, and installation requirements of combiner boxes to meet the demands of the solar PV system and mitigate potential hazards.

How to Choose the Best Solar Combiner Box for

Apr 27, 2025 · Looking for the best solar combiner box for your solar installation? Learn about different types of combiner boxes, including their components like

光伏系统解决方案 Photovoltaic system solutions

Jan 27, 2021 · In the solar PV power generation system, the smart PV combiner box reduces the connection between the solar PV cell array and the inverter.

6 FAQs about [Can the photovoltaic grid-connected combiner box be opened ]

What is a combiner box in a PV system?

In the PV power generation system, the combiner box is a wiring device that ensures the orderly connection of PV modules and the function of combining. The device can ensure that the PV system is easy to cut off the circuit during maintenance and inspection, and reduce the scope of power outage when the PV system fails.

What is a solar combination box?

The solar Combiner Box ensures the efficient and safe operation of the PV system by pooling the DC output of multiple PV modules, providing circuit protection and real-time monitoring. It plays a key role in PV systems to simplify wiring and improve system safety and overall efficiency.

How do you disconnect a PV combiner box?

Ensure the circuit breaker is in the “OFF” or “TRIP” position (or the load isolation switch is in the “OFF” position) to disconnect the combiner box from the PV DC output side. All fuse holders inside the combiner box should be open (or remove the fuse core using specialized pliers) to disconnect the DC combiner box from the PV string input side.

Which IP65 PC enclosure combiner box is suitable for residential PV panels?

In general, the IP65 PC enclosure combiner box of BENY 600v is suitable for this kind of residential PV panel, which adopts modern design and greatly reduces the space during installation. 2. Solar PV Systems On Rooftop Of Commercial Building:

What is the difference between DC & AC combiner box?

The DC combiner box can realize multiple inputs and multiple outputs. The input depends on the number of PV strings and PV panels, and the output depends on the number of inverters. The AC combiner box is one more input and one output. The function of the combiner box is to collect the current. 1.

Which IP65 enclosure iron box is suitable for a large PV power plant?

In general, the IP65 enclosure iron box of BENY 1500V combiner box is suitable for the construction of such large PV Power Plant projects, which are used to efficiently generate and improve the output of solar power generation with very little time and cost. BENY combiner box can meet the customized needs of customers.

Learn More

- How much does a photovoltaic grid-connected combiner box cost

- Photovoltaic power generation system with combiner box

- DC combiner box in photovoltaic system

- Outdoor ip65 photovoltaic combiner box power supply

- Photovoltaic combiner box slot

- Nicosia Photovoltaic Combiner Box Wholesale

- Dili Photovoltaic Combiner Box Supplier

- The role of the Peruvian photovoltaic combiner box

- Photovoltaic combiner box module

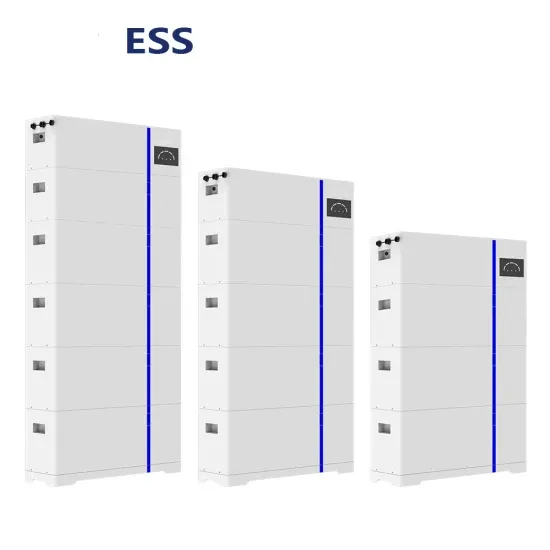

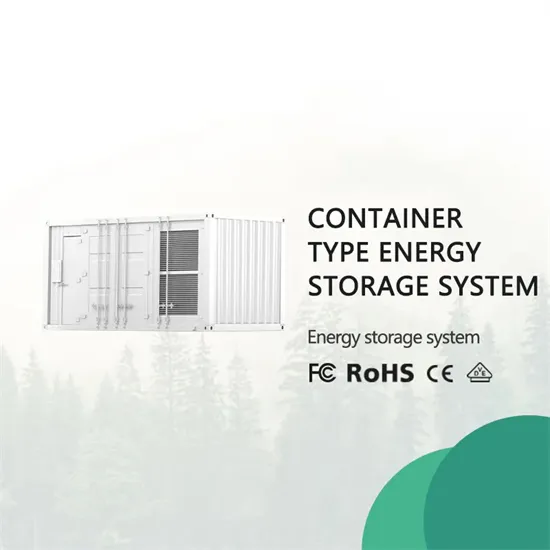

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.