Square aluminum shell lithium-ion battery energy storage

ACEIN Gathering Square Shell Energy Storage Cells is a technology enterprisespecializing in the design,development,manufacturing and sales of energy storage lithium-ion cells and battery

Square, Cylindrical, Soft Pack: Analysis of Manufacturing

Jun 10, 2025 · In the new energy era, lithium batteries, as the core power and storage units, are of undeniable importance. Among the many characteristics of lithium batteries, the packaging

What are the advantages and disadvantages of square lithium-ion batteries?

Aug 4, 2025 · In large-scale applications, there is a problem where the system lifespan is much lower than the individual lifespan. The performance advantages and disadvantages of square

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

Process flow diagram for square lithium-ion battery

Download scientific diagram | Process flow diagram for square lithium-ion battery manufacturing. from publication: A risk analysis method for potential failure modes in the lithium-ion...

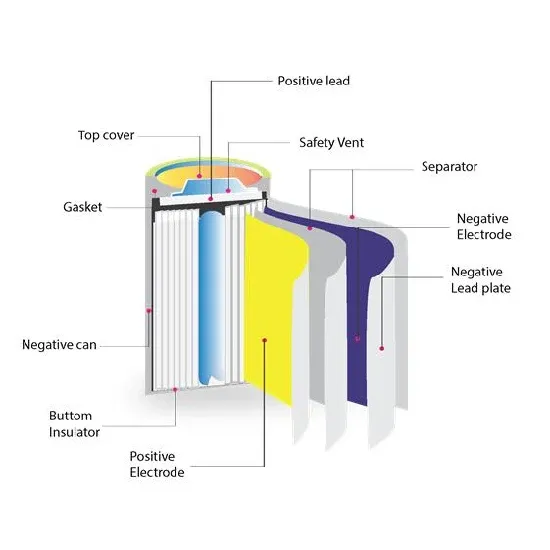

Understanding the Structure of Square Lithium Batteries

Aug 24, 2024 · Square (or prismatic) lithium batteries are widely used in energy storage systems and electric vehicles due to their compact design and high energy density. Unlike cylindrical

Lithium-Ion Battery Pack Manufacturing Process

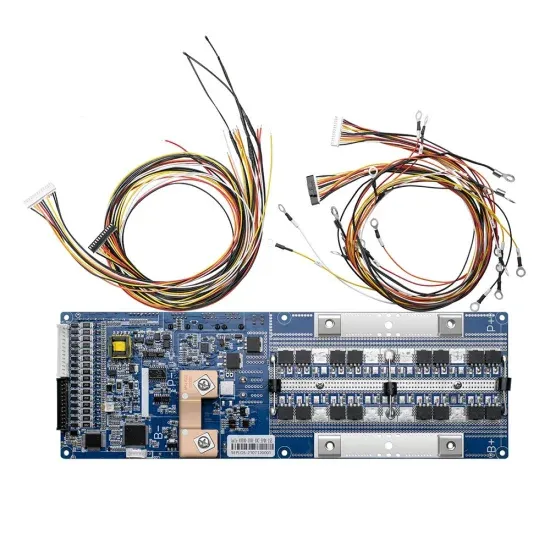

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Lithium Battery Lab Machine

Jun 21, 2023 · The demand for high-performance lithium-ion batteries has been on the rise in various industries such as electric vehicles, portable electronics, and energy storage systems.

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will explore the world of battery

How should we deal with and handle the problems of square lithium

May 2, 2025 · "How to Tackle and Manage Challenges of Square Lithium Batteries: A Comprehensive Guide" Square lithium batteries, commonly used in electric vehicles (EVs),

Process flow diagram of square lithium-ion battery assembly

To enhance product quality and operational safety of lithium-ion batteries, this paper proposes a risk analysis method based on an optimized Failure Modes and Effects Analysis (FMEA).

Prismatic cell assembly machine

Sep 8, 2023 · A prismatic battery assembly line is an industrial machine used for the automated manufacturing of prismatic (rectangular or square) lithium-ion battery cells. Prismatic cells

Square, Cylindrical, Soft Pack: Analysis of Manufacturing

Jul 14, 2025 · Cell Assembly: The core of square lithium batteries is meticulously complex in its assembly. Positively and negatively charged layers and separators are stacked or wound into

Square, Cylindrical, Soft Pack: Analysis of Manufacturing

Jul 17, 2025 · The square lithium battery is known for its regular shape, which offers significant advantages in space utilization. Its flat structure can be tightly arranged, making it suitable for

Monaco square lithium battery assembly

How do I assemble a lithium battery pack? Step-by-Step Guide to Assembling a Lithium Battery Pack 1. Prepare and Check Battery Cells Inspect the Cells: Ensure all cells are functional and

Square lithium battery assembly method

lithium battery pack assembly process. At every stage, inline testing and inspection stations meticulously verify the integrity of the cell connections, ensuring that each weld or bolt meets

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · Cell assembly: The cell is the core part of the square lithium battery, and its assembly process is rigorous and complicated. After the positive and negative electrodes and

What Are Square Batteries and Their Characteristics?

Apr 11, 2025 · Square batteries, also known as prismatic cells, are rectangular-shaped power sources with layered internal structures. Their flat design maximizes space efficiency, making

Learn More

- Lithium battery assembly energy storage

- Uganda lithium battery pack 72v assembly

- Venezuela EKncm square lithium battery

- Assembly of lithium battery in battery cabinet

- Square lithium battery equipment and price

- Lithium battery assembly pack equipment

- Dakar energy storage lithium battery assembly and production

- Lithium battery home energy storage

- Lithium battery pack increases capacity

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.