How to design an energy storage cabinet: integration and

Jan 3, 2025 · Efficient heat dissipation design: Lithium batteries and inverters will generate a certain amount of heat during operation, so the energy storage cabinet requires an effective

Why you shouldn''t charge lithium-ion batteries

May 22, 2025 · Where can you safely charge your lithium-ion (bike) batteries? And why is a safety cabinet – also known as a flammable storage cabinet –

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints.

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Lithium Battery Assembly and Usage Best Practices Guide

Feb 20, 2024 · Correct assembly and use of lithium batteries is the key to ensuring their safety and performance. Let''s learn the assembly methods and precautions of lithium batteries

Lithium-ion battery systems for ABB UPS solutions

Mar 16, 2024 · When you want power protection for a data cen-ter, production line or any other type of critical process, lithium-ion battery solutions provide peace of mind and the

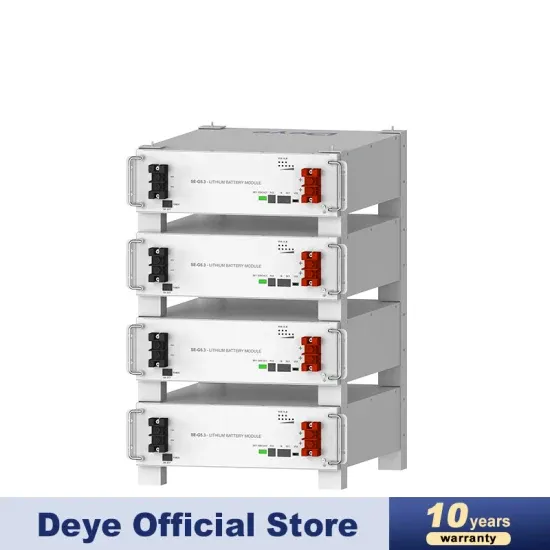

How to Install a Rack Lithium Battery System in 2025

Feb 21, 2025 · Installing a rack lithium battery system is essential for ensuring reliable power supply in data centers and server rooms in 2025.? How do you install a rack lithium battery

Lithium Battery Assembly Method and Precautions

Apr 11, 2024 · This article will introduce the assembly methods and precautions of lithium batteries to help readers better understand how to assemble lithium batteries correctly and safely.

Lithium Battery Safety Procedure

Feb 29, 2024 · Ensure that written standard operating procedures (SOPs) for lithium and lithium-ion powered research devices are developed and include methods to safely mitigate possible

How Are Lithium Batteries Assembled?

May 2, 2025 · Understanding the assembly process of lithium batteries is crucial for ensuring their optimal performance, safety, and reliability. This article explains how lithium batteries are

Lithium battery energy storage cabinet assembly method

Our cutting-edge battery charger cabinets, seamlessly integrated within our Lithium-Ion Energy Storage Cabinet lineup, ensure secure and fire-resistant containment during battery charging.

Managing Lithium Battery Risks: From Supply Chain to

Nov 7, 2024 · Lithium Battery Risks Lithium-ion batteries power essential devices across many sectors, but they come with significant safety risks. Risks increase during transport, handling,

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

Comprehensive Guide to Battery Aging Cabinet and

Aging Equipment is used to perform aging tests on lithium-ion battery packs, simulating the working conditions of the batteries in actual use. Through long-term charge-discharge cycling

Assembly diagram of lithium battery energy storage

The lithium-ion battery charging cabinet is built using all-welded, 18-gauge (1mm) steel and includes a double wall with 1.5" (38mm) of insulating air space to absorb the energy of

6 Battery Energy Storage Systems — Lithium | UpCodes

This section applies to battery energy storage systems that use any lithium chemistry (BESS-Li). Unoccupied structures housing BESS-Li must comply with NFPA 855, except where modified

6 FAQs about [Assembly of lithium battery in battery cabinet]

What is lithium ion battery assembly?

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

What is battery assembly?

Battery assembly is the process of assembling parts to create a functioning battery. This involves combining essential components like cells and connectors. Using the right tools and following precise steps is necessary to ensure the battery works properly.

What is a lithium ion battery?

Composition: Lithium-ion batteries (Li-ion) use lithium compounds as electrolytes, allowing ions to move between the anode and cathode during charging and discharging. Structure: Typically cylindrical or prismatic, manufacturers widely use them in consumer electronics, electric vehicles, and energy storage systems.

What materials are used in lithium batteries?

Cathode: Lithium batteries use various materials for the cathode, such as lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium nickel manganese cobalt oxide (NMC), and lithium iron phosphate (LFP). Each cathode material offers different performance characteristics, including energy density and stability.

Why do lithium batteries use graphite?

Anode: Lithium batteries typically use graphite for the anode, which has a structure enabling it to intercalate lithium ions during charging. This process is essential for storing energy efficiently.

What is a lithium polymer battery (LiPo)?

Composition: Lithium polymer batteries (LiPo) use a solid polymer electrolyte instead of liquid, enabling flexibility in design and shape. Structure: Commonly found in slim, lightweight pouch formats, manufacturers favor them for applications where the form factor is critical, such as smartphones and wearable devices.

Learn More

- Bern Energy Storage Cabinet Battery Assembly

- Liquid-cooled energy storage lithium iron phosphate battery station cabinet

- Lithium battery cabinet cells and cylindrical cells

- Energy storage cabinet lithium battery franchise

- Southern Europe lithium battery station cabinet enterprise

- Lithium battery station cabinet sea transportation

- How long does it take for the lithium iron phosphate battery station cabinet to charge the base station

- Caracas ranks first among lithium battery station cabinet manufacturers

- Energy storage cabinet lithium battery patent

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.