Semi-Automatic Lithium-ion Battery Assembly

Mar 1, 2024 · Discover how Semco Infratech blends precision and automation in its semi-automatic lithium-ion battery assembly line to deliver reliable, efficient,

How are Lithium-ion Battery Packs Manufactured?

Did you know that the lithium-ion battery packs in smartphones or electric vehicles (EVs) are the result of a fascinating blend of precision engineering and cutting-edge technology? These

Self-assembly formation of solid-electrolyte interphase in gel

Aug 1, 2023 · Lithium-metal batteries (LMBs) using limited-Li anodes are imperative for realizing high-energy storage. Proper solid-electrolyte interphase (SEI) design to control Li-deposition

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · Lithium-based batteries power our daily lives from consumer electronics to national defense. They enable electrification of the transportation sector and provide stationary grid

Kitjia Lithium Battery Energy Storage Assembly: Powering

Aug 18, 2021 · Kitjia lithium battery energy storage assembly systems are shaking up how we store and use energy—but let''s cut through the jargon and see what this really means for you.

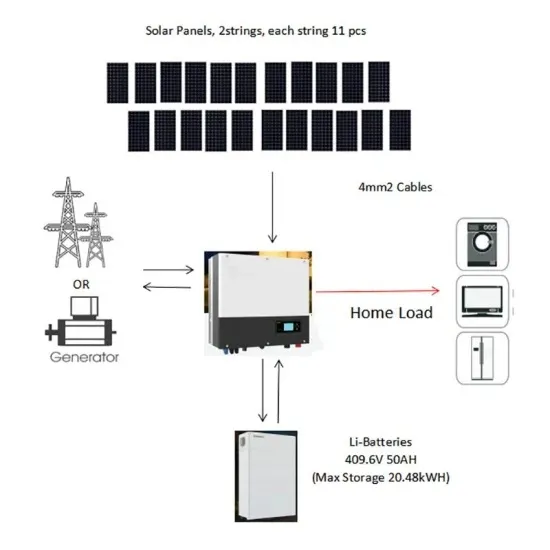

Assembly diagram of lithium battery energy storage

A battery energy storage system is of three main parts; batteries, inverter-based power conversion system (PCS) and a Control unit called battery management system (BMS). Figure

Lithium-Ion Battery Manufacturing: The Art and Science of Assembly

Apr 17, 2025 · Lithium-ion battery manufacturing is the process of producing rechargeable batteries that power modern devices like smartphones, EVs, and grid storage systems. The

Advancements and challenges in lithium-ion and lithium

Apr 25, 2025 · Lithium-ion (LI) and lithium-polymer (LiPo) batteries are pivotal in modern energy storage, offering high energy density, adaptability, and reliability. This manuscript explores the

How Are Lithium Batteries Manufactured? A Step-by-Step

How are lithium batteries made step by step? Lithium batteries are manufactured through a multi-stage process: raw material preparation, electrode production, cell assembly, electrolyte

Lithium Battery Cell Assembly Machine Market Size And

Nov 17, 2024 · Conclusion Lithium battery assembly machines are central to the electric vehicle and energy storage revolutions. As the world shifts towards clean energy solutions, the

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · Renewable Energy Storage: As society moves towards harnessing solar and wind energy, lithium-ion batteries are integral in storing this energy for later use. They help stabilize

Industrial & Commercial Energy Storage Module Production:

Automated assembly line, battery module production, laser welding, energy storage. 2: Introduction: This automated assembly line consists of three main sections: cell sorting,

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power density, and long cycle

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Manufacturing Process of Lithium-ion Batteries for Home Energy Storage

2 days ago · Home energy storage batteries are produced through a carefully controlled multi-stage process involving electrode preparation, cell assembly, and final processing. The

6 FAQs about [Lithium battery assembly energy storage]

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

How does a lithium battery pack work?

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment. Quality Control: Every step, from mixing to testing, demands extreme precision. Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

What are the three stages of lithium-ion battery assembly?

The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell-making machine workflow.

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

How is a lithium ion battery assembled?

The second stage of the lithium-ion battery assembly process involves assembling the core components. Winding/Stacking: Positive and negative electrodes are alternately layered with separators to form a cell stack. Electrolyte Filling: The electrolyte is carefully injected into the cells to enable ion movement.

Learn More

- Lithium battery assembly energy storage

- Tiraspol lithium battery energy storage fire protection system

- Argentina Energy Storage System Lithium Battery Factory

- 21700 Lithium Battery Energy Storage

- Belgrade lithium battery energy storage

- Bangladesh lithium iron phosphate energy storage battery

- Botswana energy storage lithium battery manufacturer

- 72v energy storage lithium battery

- Chile energy storage lithium battery factory

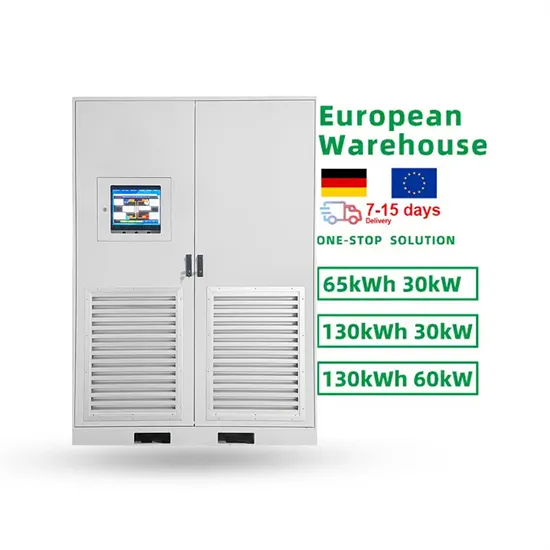

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.