Lithium LiFePO4 Batteries for Trolling Motors

Apr 26, 2025 · Lithium-iron-phosphate (LiFePO₄) batteries weigh roughly 60% less than equivalent lead-acid units, deliver high-current output, and last far

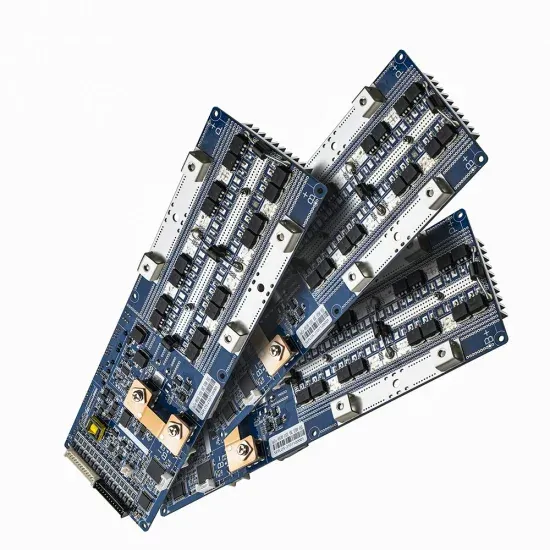

Battery BMS Advantages: From Functional Safety to Cost

Aug 18, 2025 · Battery BMS Advantages: From Functional Safety to Cost Reduction An efficient battery BMS (Battery Management System) is more important than ever as the need for high

Advantages and Disadvantages of Lithium-Ion Batteries You

Feb 18, 2025 · Lithium-ion batteries have become a staple in modern technology, powering everything from smartphones to electric vehicles. As the demand for these batteries continues

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · Overall, a BMS enhances battery reliability and safety during charging and discharging operations. Without a BMS, lithium-ion batteries can overcharge or over

Understanding lithium-ion battery management systems in

Dec 1, 2024 · Lithium-ion batteries (LIBs) are key to EV performance, and ongoing advances are enhancing their durability and adaptability to variations in temperature, voltage, and other

Pros and Cons of Lithium-Ion Battery: A Comprehensive Guide

Aug 16, 2024 · Discover the pros and cons of lithium-ion batteries in this comprehensive guide. Learn about high energy density, quick charging, and more.

Analysis of the advantages and disadvantages of BMS

Apr 9, 2025 · In the design of the BMS, the control methods of the positive terminal (positive electrode) and the negative terminal (negative electrode) of the battery have their own

Do All Lithium Batteries Have a Built-in BMS?

Oct 24, 2024 · Not all lithium batteries come with a built-in Battery Management System (BMS). While most modern lithium-ion batteries, especially those used in applications like electric

Understanding lithium-ion battery management systems in

Dec 1, 2024 · The future of transportation is moving toward electric vehicles (EVs), driven by the global demand for sustainability. At the core of EV technology is the Battery Management

1S, 2S, 3S, 4S BMS Circuit Diagram for Li-ion

Jan 1, 2025 · In this guide, we will dive deep into BMS circuit diagram for 1S, 2S, 3S, and 4S Li-ion battery configurations, providing detailed explanations of its

What is a Battery Management System (BMS)? –

1 day ago · Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically

Can I Run a Lithium Battery Without a BMS?

Dec 6, 2023 · Running a lithium battery without a Battery Management System (BMS) is technically possible, but it poses significant risks. A BMS is crucial for monitoring battery

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · The BMS provides overcurrent protection, which helps prevent fire risks. Overall, a BMS enhances battery reliability and safety during charging and discharging operations.

LiFePO4 Battery vs. Lithium-ion Polymer (LiPo): Which One

3 days ago · LiFePO4 Battery vs. Lithium-ion Polymer (LiPo): Which One Should You Choose? Expert comparison of chemistry, safety, energy density, cycle life, temperature performance,

6 FAQs about [Disadvantages of lithium battery BMS]

What is a lithium battery BMS?

When you hear talk about lithium batteries, the word BMS is always mentioned. BMS stands for Battery Management System, but few people know what it is and its function. In this article we’ll explain it to you in a simple way.

Are lithium ion batteries safe?

To reduce these concerns, appropriate waste management measures are vital [170, 205]. Battery-related hazards: Lithium-ion batteries, while generally safe, can pose fire and explosion risks if damaged, improperly handled, or exposed to extreme conditions. These incidents can result in health and safety hazards .

Are lithium-ion batteries good for EVs?

Lithium-ion batteries (LIBs) are key to EV performance, and ongoing advances are enhancing their durability and adaptability to variations in temperature, voltage, and other internal parameters. This review aims to support researchers and academics by providing a deeper understanding of the environmental and health impact of EVs.

Why do lithium batteries go out of balance?

They also have a weak point, however: manufacturers are unable to ensure production uniformity from one lithium cell to another. Although all of their characteristics exceed rated values, the cells present: With use or, simply, with the passing of time, these differences, even if small, cause the cells inside the battery to go out of balance.

What are the disadvantages of a BMS?

This translates into machines that do not complete their mission and vehicles that lose driving range with each cycle. High maintenance costs: with a conventional BMS, an element cannot be replaced on site; batteries having those systems are normally sent back to the manufacturer, incurring high shipping costs.

How dangerous is the sulphuric acid in a lithium ion battery?

The sulphuric acid in the battery is very dangerous. The operational temperature and voltage stand as the critical factors governing the operation of lithium-ion cells . As indicated in Fig. 12, Fig. 13, the cell's voltage, current, and temperature must be sustained within the specified "Safe Operating Area" (SOA).

Learn More

- Power lithium battery bms system

- Bandar Seri Begawan outdoor power lithium battery bms wholesale

- Austrian energy storage lithium battery bms

- Lithium battery BMS standard

- Disadvantages of lithium battery packs

- Lisbon lithium battery bms module manufacturer

- Kigali lithium battery bms manufacturer

- Bogota lithium battery bms module

- What does lithium battery upgrade BMS mean

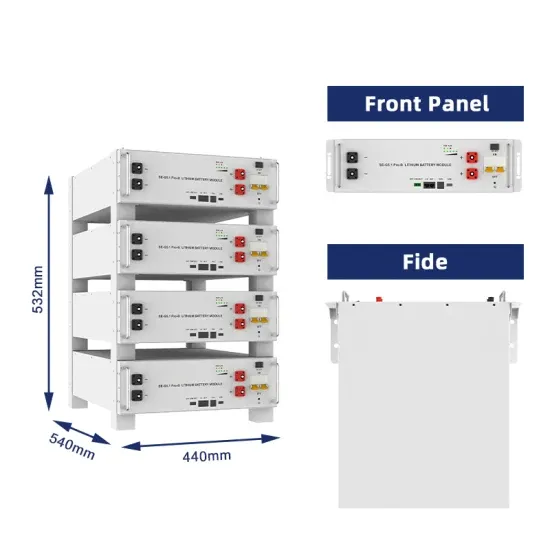

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.