Estimating the Effects of Module Area on Thin-Film

Mar 30, 2018 · Abstract — We investigate the potential effects of module area on the cost and performance of photovoltaic systems. Applying a bottom-up methodology, we analyzed the

Thin Film Photovoltaics

Jan 1, 2018 · Thin film solar cell technology has recently seen some radical advancement as a result of new materials and innovations in device structures. The increase in the efficiency of

Mitsubishi Thin Film Photovoltaic Module

May 13, 2021 · The thin-film (a-Si) PV module is a nections of modules, the effect of voltage drop due to technology highly expected as a module for low manufactur- shadow (shade) can be

Thin-film solar cells: review of materials, technologies and

Apr 3, 2007 · The recent boom in the demand for photovoltaic modules has created a silicon supply shortage, providing an opportunity for thin-film photovoltaic modules to enter the market

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · One of the main obstacles that came in the way of large-scale production and expansion of photovoltaic (PV) systems has been the steep price of the solar cell modules.

Thin Film Solar Panel In India: Types, Solar Price

Jun 28, 2022 · A solar panel can convert the sunlight into usable electrical energy for daily consumption. This process works on the principle of the photovoltaic

Integrating Thin-Film Photovoltaics Ont; Building

Mar 27, 2025 · Installation methods include thin-film photovoltaic modules laminated to single-ply membranes; flexible photovoltaic modules combined with elastomeric coatings applied over

What are thin-film solar cells? description, and types

Sep 26, 2019 · Silicon modules are divided into three categories: Amorphous silicon photovoltaic cells Multicrystalline tandem photovoltaic cells Multicrystalline silicon thin film on glass The

Thin Film Photovoltaics

Oct 7, 2013 · Since sunlight carries relatively little energy in comparison with combustion-based energy sources, photovoltaic (PV) modules must be cheap to produce energy that can be

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · Harnessing the sun''s energy to produce electricity has proven to be one of the most promising solutions to the world''s energy crisis. However, the device to convert sunlight to

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · Production costs of thin-film solar panels are competitive and module efficiencies of CdTe and CIGS cells are in the same range as the Si-leader [10]. However, thin-film PV is still

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros

Jul 22, 2025 · Thanks to their ultra-thin profile, just 0.3 mm thick thin film modules can blend effortlessly into rooftops, facades, windows, or even curved surfaces. This makes them ideal

Solar Photovoltaic Manufacturing Basics: A Beginner''s Guide

2 days ago · Solar photovoltaic manufacturing is a blend of science, engineering, and cost optimization. From silicon PV and thin film PV to racking systems and power electronics, every

Thin-Film Solar Panels

Feb 27, 2021 · B. How Thin-Film Solar Cells are Made? Thin-Film solar cells are by far the easiest and fastest solar panel type to manufacture. Each thin-film solar panel is made of 3 main parts:

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · Thin film solar cells typically cost $0.50 to $1 per watt on average, but they typically have a shorter lifespan of 10-20 years compared to other

Thin-film CdTe photovoltaics – The technology for utility

Oct 1, 2018 · Photovoltaics is an important energy technology for large scale energy generation. In the past few years cost of photovoltaic module manufacturing and

6 FAQs about [Thin-film photovoltaic module cost]

Can thin-film solar cells reduce the cost of photovoltaic systems?

One of the main obstacles that came in the way of large-scale production and expansion of photovoltaic (PV) systems has been the steep price of the solar cell modules. Later, researchers developed one of the solutions to reduce this cost is by creating thin-film solar cells.

How much does thin film solar cost?

The cost of a portable thin-film station, which is a common application of thin-film solar technology, ranges from under $1,000 to around $5,000. The exact costs, however, depend on the wattage and battery capacity of the system. What Are the Advantages of Using Thin-Film Solar Cells?

What are solar photovoltaic modules?

Solar photovoltaic modules are in general called solar panels. They convert sunlight to solar energy. Several solar cells are used to create PV modules. Semiconductor materials such as silicon are used to make these solar cells. Three main types of solar panels used today are: 1. Monocrystalline 2. Polycrystalline 3. Thin film

Who makes thin-film solar panels?

Unlike the conventional solar panels, thin-film solar panels do rely on quality molten silicon ingots for production. The following are the leading manufacturers of thin-film PV: First Solar – First Solar is a leading company in producing the CdTe thin-film solar cells. As of now, First Solar has only served the commercial market.

What is the efficiency of thin-film solar modules?

The level of efficiency of thin-film modules is between 6 and 10%. It means for these solar cells to achieve the same performance as the crystalline modules, thin-film modules need to be installed in a comparatively larger area. The performance of thin-film solar modules is reduced due to degradation.

How are thin-film solar panels made?

These days, it is possible to have large-scale production of thin-film solar panels. To produce these solar panels, manufacturers first spray the photovoltaic (PV) substances onto a solid surface similar to glass, and from which a solar panel is made.

Learn More

- Which thin-film photovoltaic module manufacturer is better in Singapore

- Thin-film photovoltaic module conversion efficiency

- Thin-film photovoltaic module subsidies

- Thin-film photovoltaic module brand

- How much does a double-glass bifacial photovoltaic module cost

- Huawei photovoltaic energy storage module

- How much does a meal of photovoltaic glass cost

- How much does Magadan solar photovoltaic panels cost

- How much does the photovoltaic panel BESS roof cost

Industrial & Commercial Energy Storage Market Growth

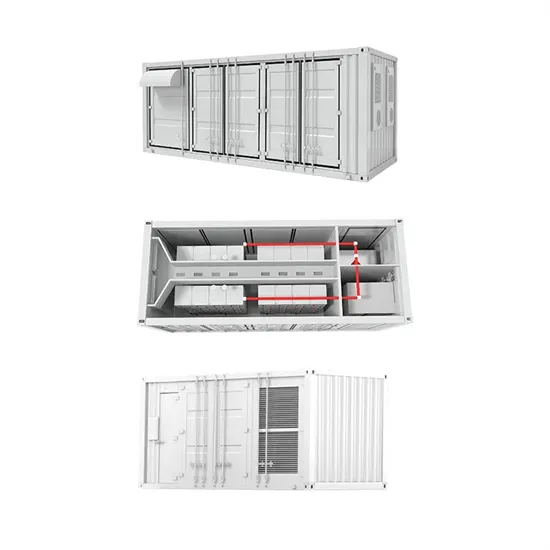

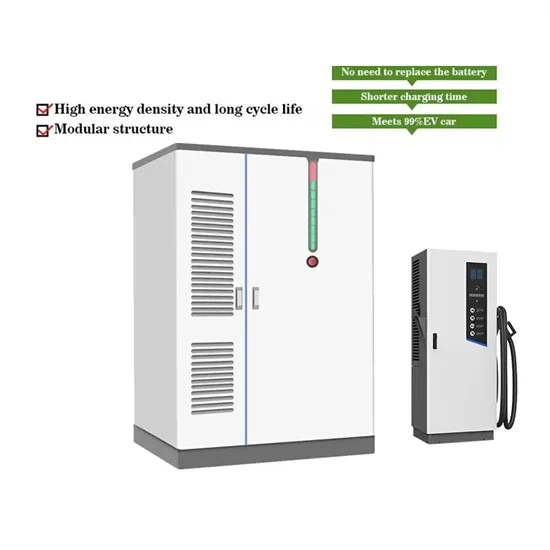

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.