Supply risks associated with CdTe and CIGS thin-film

Sep 15, 2016 · This strong market growth – aided in many countries by subsidies and generous feed-in tariffs – has been accompanied by substantial price decreases in recent years. The

Challenges and Opportunities for Improving Thin-Film

Here we summarize challenges and opportunities for CdTe and CIGS PV research and show that a substantial effort is still needed in areas such as device design and material improvement to

The impact of phasing out subsidy for financial

Oct 16, 2024 · Taking the "531 New Policy" of China''s photovoltaic industry as an exogenous shock, based on the sample of listed companies in Shanghai and

Thin Film Photovoltaics

Jan 1, 2018 · Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Estimating the Effects of Module Area on Thin-Film

Mar 30, 2018 · Abstract — We investigate the potential effects of module area on the cost and performance of photovoltaic systems. Applying a bottom-up methodology, we analyzed the

Cadmium Telluride Market | Size, Price, import, export,

1 day ago · First Solar, while primarily a module manufacturer, significantly influences the CdTe supply chain through its captive consumption and technological partnerships. The company''s

An environmental life cycle comparison of single-crystalline

Dec 1, 2013 · GHG emissions from building integrated photovoltaic modules are approximately one-third of the emissions of standard single-crystalline and thin-film modules. BIPV modules

Summary Of Photovoltaic Policies in Various Countries

Apr 9, 2025 · Shenzhen: Provide 0.4 yuan/kWh subsidy for thin-film photovoltaic demonstration projects built from 2022 to 2025, requiring access to the virtual power plant management cloud

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition

PV cells and modules – State of the art, limits and trends

Dec 1, 2020 · In the past, the development of the photovoltaic industry was dependent on subsidies but the current rapid development is possible only when the price of electricity

Thin-Film Solar Photovoltaics: Trends and Future Directions

Dec 5, 2024 · Thin-film solar cell can be cost-effective because of minimal material usage, flexibility, and potential high efficiency. The traditional thin-film solar techno

China''s Export Control on Cadmium Telluride

Feb 6, 2025 · If raw material supply remains constrained for an extended period, it may accelerate the industry''s transition to crystalline silicon or other thin-film

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · Rigid thin-film cells have other commercial applications (inserting or interleaving between two panes of glass) in some of the largest photovoltaic power stations in the world.

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · CIGS and CdTe hold the greatest promise for the future of thin film. Longevity, reliability, consumer confidence and greater investments must be established before thin film

PV cells and modules – State of the art, limits and trends

Dec 1, 2020 · Currently, thin film technology modules are lagging behind crystalline silicon modules in both efficiency and cost, and have a somewhat shorter service life. The advantage

What are thin-film solar cells? description, and types

Sep 26, 2019 · Silicon modules are divided into three categories: Amorphous silicon photovoltaic cells Multicrystalline tandem photovoltaic cells Multicrystalline silicon thin film on glass The

Thin-Film Solar Panels

Feb 27, 2021 · B. How Thin-Film Solar Cells are Made? Thin-Film solar cells are by far the easiest and fastest solar panel type to manufacture. Each thin-film solar panel is made of 3 main parts:

A new strategy for improving the efficiency of thin-film solar

Jun 24, 2025 · This work provides a defect engineering strategy for high-quality CZTSSe films and reveals the mechanism linking sodium-mediated selenization kinetics to structural uniformity,

Advancing U.S. Thin-Film Solar Photovoltaics Funding Program

1 day ago · Projects will de-risk tandem thin-film technologies that include perovskite materials. Projects will also support innovation in cadmium telluride (CdTe) production by improving

6 FAQs about [Thin-film photovoltaic module subsidies]

What is thin-film photovoltaic (TFPV)?

The development of this technology is closely linked to advancements in thin-film photovoltaic (TFPV) technologies, which provide greater flexibility, enhanced aesthetics, and potential cost advantages compared to conventional crystalline silicon solar cells.

Does decreasing subsidies affect the financial performance of downstream photovoltaic enterprises?

Considering the difference of industrial chain links, the negative impact of decreasing subsidies on the financial performance of downstream photovoltaic enterprises is more significant, among which R&D investment plays a partially intermediary role.

Does China's government subsidy policy promote photovoltaic development?

In the past two decades, China's government subsidy policy has promoted the rapid development of the photovoltaic industry. Concerns have been raised about h...

Are thin-film solar cells cost-effective?

Thin-film solar cell can be cost-effective because of minimal material usage, flexibility, and potential high efficiency. The traditional thin-film solar techno

Do subsidies affect the financial performance of PV firms?

From the perspective of the industry life cycle, there is an inverted U-shaped relationship between subsidies and firms’ output, driven by the resource allocation effect of subsidies and the signaling effect of investment (Du et al., 2023). Research has explored the impact of subdivided industrial policies on the financial performance of PV firms.

How does the subsidy program affect PV power generation?

The revenue of PV power generation plants under the subsidy program mostly derives from two sources: electricity sales and government subsidies. Following the reduction of the subsidy, government support is either diminished or entirely revoked, leading to a decrease in the project’s overall revenue.

Learn More

- Which thin-film photovoltaic module manufacturer is better in Singapore

- North Korean thin-film photovoltaic module prices

- Thin-film photovoltaic module manufacturer in Barcelona Spain

- Thin-film photovoltaic module brand

- Photovoltaic module manufacturers exported from Dili

- What are the types of photovoltaic module batteries

- What are the requirements for photovoltaic module planning

- South Sudan polycrystalline photovoltaic module panels

- Kigali Solar Photovoltaic Module Enterprise

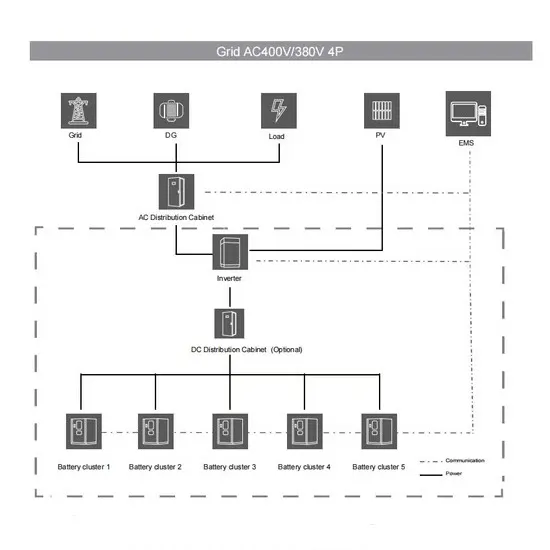

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.