Underwater performance of thin-film photovoltaic module immersed

Dec 1, 2019 · This article presents the experimental results of the underwater performance of amorphous silicon (a-Si) thin-film photovoltaic (TFPV) module. Electrical performance

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · Thin film solar cells are favorable because of their minimum material usage and rising efficiencies. The three major thin film solar cell technologies include amorphous silicon

Current–voltage characteristics and quantum efficiency spectra

Jan 1, 2014 · CdTe together with a-Si and CuIn x Ga 1−x Se 2 (CIGS) are the three most common photovoltaic (PV) materials used in the mass production of thin-film modules at present. The

Improved conversion efficiencies of thin-film silicon tandem

Jan 1, 2016 · Increased electrical power generated from a thin-film silicon (TF-Si) photovoltaic device can lead to a reduced cost of electricity production that will support the mass adoption

Progress in Thin-Film Photovoltaics: A Review of Key

Mar 20, 2025 · Thin-film solar cells (TFSCs) represent a promising frontier in renewable energy technologies due to their potential for cost reduction, material efficiency, and adaptability.

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · Thin-film solar cells are a type of solar panel or semiconductor devices that convert sunlight into electricity through the photovoltaic effect.

Editorial: Emerging thin-film solar cell research

Jun 16, 2025 · Thin-film photovoltaics, particularly those based on perovskite materials, are revolutionizing solar energy research through rapid efficiency gains, innovative device

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Thin-Film Solar Photovoltaics: Trends and Future Directions

Dec 5, 2024 · Thin-film solar cell can be cost-effective because of minimal material usage, flexibility, and potential high efficiency. The traditional thin-film solar technologies include

Record 12.34% stabilized conversion efficiency in

Jun 26, 2015 · Mass‐adoption of thin‐film silicon (TF‐Si) photovoltaic modules as a renewable energy source can be viable if the cost of electricity production

Enhanced Efficiency in Thin Film Solar Cells: Optimized

Jun 3, 2024 · This paper introduces a highly effective method to enhance the power conversion efficiency of thin-film solar cells with a microcrystalline absorber layer. The

Lightweight and flexible Cu(In,Ga)Se2 solar minimodules:

Oct 30, 2022 · Lightweight and flexible photovoltaic solar cells and modules are promising technologies that may result in the wide usage of light-to-electricity energy conversion devices.

Assessment of Energy Conversion Efficiency in Solar Cells: A

Feb 19, 2025 · Results indicated that monocrystalline cells consistently achieved the highest energy conversion efficiency, reaching 19.1% at 25°C and 80,000 luces, while polycrystalline

First Solar Achieves World Record 18.6% Thin

Jun 17, 2015 · Executing to industry''s most disruptive technology roadmap – More efficient than the best multi-PERC module. First Solar, Inc. announced it has

Assessment of Energy Conversion Efficiency in Solar Cells: A

Feb 19, 2025 · This study focuses on the assessment of energy conversion efficiency in different types of photovoltaic (PV) solar cells—monocrystalline, polycrystalline, and thin-film—under

Experimental comparison between Monocrystalline,

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

Photovoltaic materials: Present efficiencies and

Apr 15, 2016 · Photovoltaics, which directly convert solar energy into electricity, offer a practical and sustainable solution to the challenge of meeting the

Solar Cell Efficiency Tables (Version 64)

Sep 10, 2024 · New module efficiency record: 23.5% under 1-sun illumination using thin-film single-junction GaAs solar cells. In: Proceedings of the 38th IEEE Photovoltaic Specialists

Flexible Photovoltaic Solar Design | SpringerLink

The advancement in material science has enabled enormous developments of photovoltaic technologies. From an architectural integration viewpoint, the mechanical flexibility of the

6 FAQs about [Thin-film photovoltaic module conversion efficiency]

What are the new thin film PV technologies?

Emerging next generation thin film technologies With intense R&D efforts in materials science, several new thin-film PV technologies have emerged that have high potential, including perovksite solar cells, Copper zinc tin sulfide (Cu 2 ZnSnS 4, CZTS) solar cells, and quantum dot (QD) solar cells.

What are thin film solar cells?

Thin film solar cells are favorable because of their minimum material usage and rising efficiencies. The three major thin film solar cell technologies include amorphous silicon (α-Si), copper indium gallium selenide (CIGS), and cadmium telluride (CdTe).

How much does a thin-film solar cell cost?

The rated efficiency for GaAs thin-film solar cells is recorded at 29.1%. The cost for these III-V thin-film solar cells rounds going from $70/W to $170/W, but NREL states that the price can be reduced to $0.50/W in the future.

Are polycrystalline Thinfilm photovoltaic materials able to convert SmallCell power?

Already, several technologies of polycrystalline thin‐film photovoltaic materials have achieved certified record small‐cell power conversion efficiencies exceeding 22%. They are CdTe, Cu (In,Ga) (S,Se) 2 (CIGS), and metal halide perovskite (PSC), each named after the light-absorbing semiconductor material.

How efficient is a photovoltaic cell based on laser light?

Researchers at Fraunhofer ISE have achieved a record conversion efficiency of 68.9 % for a III-V semiconductor photovoltaic cell based on gallium arsenide exposed to laser light of 858 nanometers. This is the highest efficiency achieved to date for the conversion of light into electricity.

What are thin-film solar panels?

Thin-film solar panels use a 2 nd generation technology varying from the crystalline silicon (c-Si) modules, which is the most popular technology. Thin-film solar cells (TFSC) are manufactured using a single or multiple layers of PV elements over a surface comprised of a variety of glass, plastic, or metal.

Learn More

- Which thin-film photovoltaic module manufacturer is better in Singapore

- What is the conversion efficiency of energy storage photovoltaic power station

- Thin-film photovoltaic module subsidies

- 9BB high efficiency photovoltaic double glass module

- Thin-film photovoltaic module brand

- Thin-film photovoltaic module cost

- Thin-film photovoltaic module manufacturer in Barcelona Spain

- Photovoltaic module cell decay rate

- Amman Glass Photovoltaic Module Manufacturer

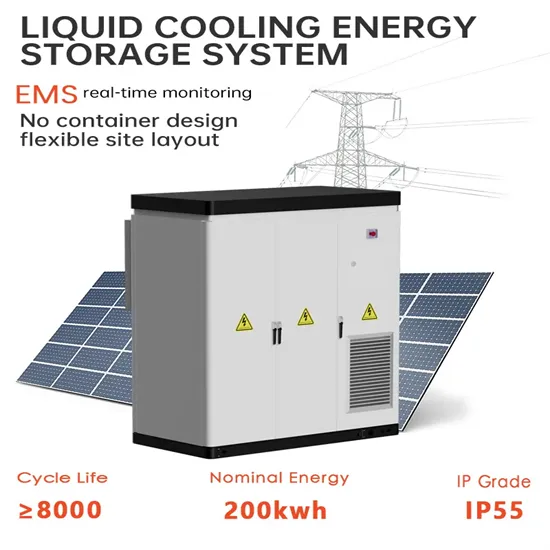

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.