Energy Storage Charging Pile Management Based on

Jan 16, 2024 · The energy storage charging pile management system for EV is divided into three to modules: manage energy the storage whole charging process pile of equipment, charging.

Introduction to charging piles and energy storage

this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and

Different Types of Battery Energy Storage Systems (BESS)

Jan 14, 2025 · Conclusion Battery Energy Storage Systems (BESS) are crucial for improving energy efficiency, enhancing the integration of renewable energy, and contributing to a more

What are the charging pile energy storage manufacturers?

Aug 7, 2024 · Energy storage systems associated with charging piles provide multiple advantages, including grid load balancing and enhanced energy security. As more electric

Which energy storage charging pile technology is more

The energy storage charging pile achieved energy storage benefits through charging during off-peak periods and discharging during peak periods, with benefits ranging from 699.94 to

Battery Energy Storage for Electric Vehicle Charging

Sep 4, 2024 · Battery energy storage systems can enable EV fast charging build-out in areas with limited power grid capacity, reduce charging and utility costs through peak shaving, and boost

What is an energy storage charging pile? | NenPower

Sep 20, 2024 · An energy storage charging pile refers to a device designed to store electrical energy, which can then be used to charge electric vehicles or other energy-consuming

Charging Piles and Energy Storage: Powering the Future of

Mar 14, 2025 · Ever wondered why your smartphone battery dies faster than your enthusiasm for gym memberships? Now imagine scaling that power anxiety to electric vehicles (EVs). This is

Modeling of fast charging station equipped with energy storage

Apr 1, 2018 · After that the power of grid and energy storage is quantified as the number of charging pile, and each type of power is configured rationally to establish the random charging

How about Suzhou energy storage charging pile? | NenPower

Mar 2, 2024 · The significance of these charging piles extends beyond mere convenience for EV users; they are instrumental in addressing broader issues of energy management. As the

Three types of battery energy storage charging piles

How does the energy storage charging pile interact with the battery management system? On the one hand, the energy storage charging pile interacts with the battery management system

Classification of charging piles-News-INFY POWER

Sep 22, 2022 · What are the main components of the EV DC charger? Charging module, main control board, communication board, man-machine interface, new energy charging gun, billing

Understanding the Charging Pile: The Future of

Feb 10, 2025 · Electric vehicles (EVs) can be charged using two current types: Alternating Current (AC) or Direct Current (DC) where charging via AC is the

Understanding Electric Vehicle Charging Piles: Common

Sep 13, 2024 · This type of product is actually not very meaningful for most individual users, because when sharing your own private charging pile with others, you need to consider many

Benefit allocation model of distributed photovoltaic power

Aug 1, 2020 · Abstract In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-power-generation carport and energy-storage charging-pile project

Understanding the Different Types of Charging

Feb 23, 2025 · A power plant that creates both electricity and heat, this is also a great way to power your car and help the environment. With clean energy, we

Energy Storage Charging Pile: The Game-Changer in EV Charging

Jul 21, 2024 · Meet the energy storage charging pile - the Swiss Army knife of EV infrastructure that''s quietly solving our biggest charging headaches. Unlike regular chargers, these smart

Underground solar energy storage via energy piles: An

Jan 15, 2022 · Energy storage needs to account for the intermittence of solar radiation if solar energy is to be used to answer the heat demands of buildings. Energy piles, which embed

Design and Application of Smart EV Charging Piles

Jun 24, 2025 · The integration of V2G, energy storage technologies, and high-performance batteries not only facilitates battery swapping services but also drives the convergence of

6 FAQs about [Which type of energy storage does the charging pile belong to ]

What are energy storage charging piles?

By balancing the electrical grid load, utilizing cost-effective electricity for storage, and supporting renewable energy integration, energy storage charging piles enhance grid stability, charging economics, and environmental performance.

What is an EV charging pile?

An EV charger or charging pile is a unit intended for supplying electric energy to an electric vehicle that requires charging in order to increase its stored energy. They act as intermediaries between the power grid and an electric vehicle (EV), controlling the current and voltage supply to ensure that charging is done efficiently and safely.

What are the components of a charging pile?

A charging pile comprises several components which are crucial for its operational functionality and security features: Power Supply Module – Converts and stabilizes the energy from the grid. Charge Controller – Smartly operates the voltage, current, and communication functions between the vehicle and the charging pile.

What is the main unit of a charging pile?

The main unit of the charging pile is the core control component, responsible for managing the operational state and output current of the charging pile. It typically includes a power module, control module, and communication module. The power module converts AC power into DC power for charging the vehicle.

What is an energy storage Charger?

An energy storage charger is an advanced device that integrates energy storage and charging functions. It can store electrical energy during low demand periods and provide charging services to electric vehicles during peak times.

How does a DC charging pile work?

Installation also requires a professional electrician for wiring. DC charging piles are designed for fast charging of electric vehicles by converting the AC power from the grid into DC power and directly delivering it to the vehicle’s battery. This significantly shortens charging time.

Learn More

- Which is better energy storage or charging pile

- Charging pile energy storage integrated

- The role of the energy storage box in the Saint Lucia charging pile

- Electric Power Equipment Photovoltaic Energy Storage Charging Pile

- Charging pile energy storage effect

- Which type of energy storage battery is used

- Can the charging pile be connected to an energy storage module

- Malabo Energy Storage Charging Pile

- Charging pile with energy storage

Industrial & Commercial Energy Storage Market Growth

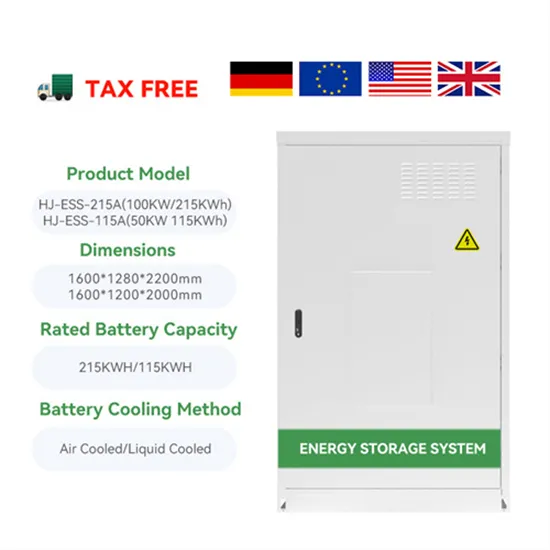

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.