Energy storage charging piles can be directly connected to

A DC Charging Pile for New Energy Electric Vehicles household batteries, together with electric vehicles connected to the grid through charging piles, can not only store electricity, but can

Benefit allocation model of distributed photovoltaic power

Aug 1, 2020 · Abstract In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-power-generation carport and energy-storage charging-pile project

New energy storage charging pile module wiring

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

Energy storage charging pile and charging system (2020)

TL;DR: In this paper, an energy storage battery is arranged on a mobile charging pile, the battery is electrically connected with an energy management system, and the EMS is equipped with

What is an energy storage charging pile? | NenPower

Sep 20, 2024 · An energy storage charging pile refers to a device designed to store electrical energy, which can then be used to charge electric vehicles or other energy-consuming

A DC Charging Pile for New Energy Electric Vehicles

Oct 16, 2023 · Abstract New energy electric vehicles will become a rational choice to achieve clean energy alternatives in the transportation field, and the advantages of new energy electric

How to connect the charging and energy storage

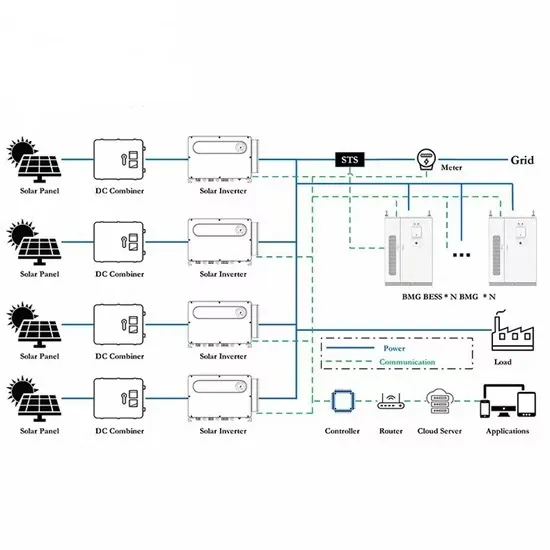

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

How to connect the energy storage charging pile interface

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

How do charging piles solve the problem of energy storage?

Jun 26, 2024 · Charging piles offer innovative and effective solutions to energy storage challenges. 1. They facilitate efficient energy transfer from renewable sources, 2. They enable

Understanding Electric Vehicle Charging Piles: Common

Sep 13, 2024 · Common indicators and functional descriptions of electric vehicle charging piles [Simple principle Before explaining the various indicators, it is necessary to briefly understand

Energy storage charging pile charging connection

This paper proposes an energy storage pile power supply system for charging pile, which aims to optimize the use and manage-ment of the energy storage structure of charging pile and

Regulation module of energy storage charging pile

Regulation module of energy storage charging pile charge control guidance module. On this basis, combined with the research of new technologies such as the Internet of Things, cloud

Energy storage charging pile module specifications

I. Construction background. Developing new energy vehicles is the only road China must take to become an advanced automobile maker from a big automobile maker, and promoting the

(PDF) Research on energy storage charging piles based on

Feb 1, 2024 · Abstract and Figures Aiming at the charging demand of electric vehicles, an improved genetic algorithm is proposed to optimize the energy storage charging piles

Energy storage facilities charging piles

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

Charging pile with energy storage battery

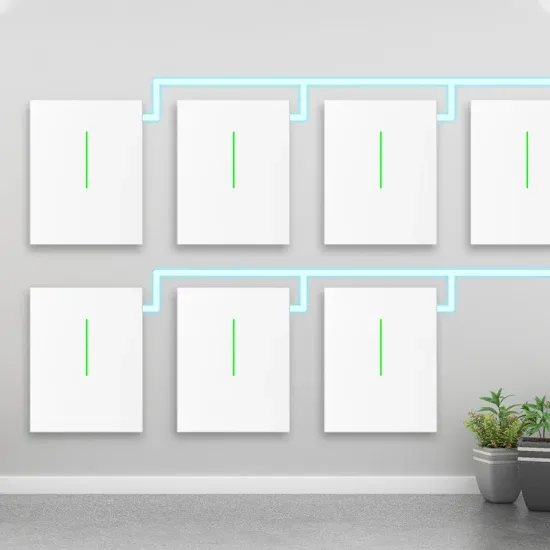

Absen''''s Pile S is an all-in-one energy storage system integrating battery, inverter, charging, discharging, and Page 1/4 Charging pile with energy storage battery intelligent control. It can

Control Strategy of Distributed Photovoltaic Storage Charging Pile

Jul 19, 2025 · Distributed photovoltaic storage charging piles in remote rural areas can solve the problem of charging difficulties for new energy vehicles in the countryside, but these storage

Optimized operation strategy for energy storage charging piles

May 30, 2024 · In response to the issues arising from the disordered charging and discharging behavior of electric vehicle energy storage Charging piles, as well as the dynamic

6 FAQs about [Can the charging pile be connected to an energy storage module ]

Can battery energy storage technology be applied to EV charging piles?

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage; Multisim software is used to build an EV charging model in order to simulate the charge control guidance module.

How a charging pile energy storage system can improve power supply and demand?

Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the charging piles of electric vehicles and optimizing them in conjunction with the power grid can achieve the effect of peak-shaving and valley-filling, which can effectively cut costs.

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

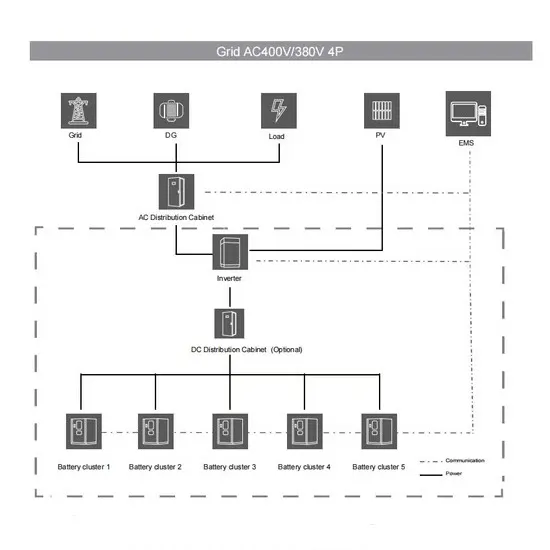

What are the parts of a charging pile energy storage system?

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time monitoring system [ 3 ].

How does a charging pile work?

The charging pile determines whether the power supply interface is fully connected with the charging pile by detecting the voltage of the detection point. Multisim software was used to build an EV charging model, and the process of output and detection of control guidance signal were simulated and verified.

What are electric vehicle charging piles?

Electric vehicle charging piles are different from traditional gas stations and are generally installed in public places. The wide deployment of charging pile energy storage systems is of great significance to the development of smart grids. Through the demand side management, the effect of stabilizing grid fluctuations can be achieved.

Learn More

- Doha charging pile brand energy storage module

- Charging pile energy storage effect

- Tunisia energy storage charging pile manufacturer

- Vientiane photovoltaic energy storage integrated charging pile

- How much does energy storage charging pile equipment cost

- AC Energy Storage Charging Pile

- Does the energy storage cabinet battery have an energy storage charging pile

- How much does Male s energy storage charging pile equipment cost

- Energy storage cabinet Energy storage Charging pile Photovoltaic

Industrial & Commercial Energy Storage Market Growth

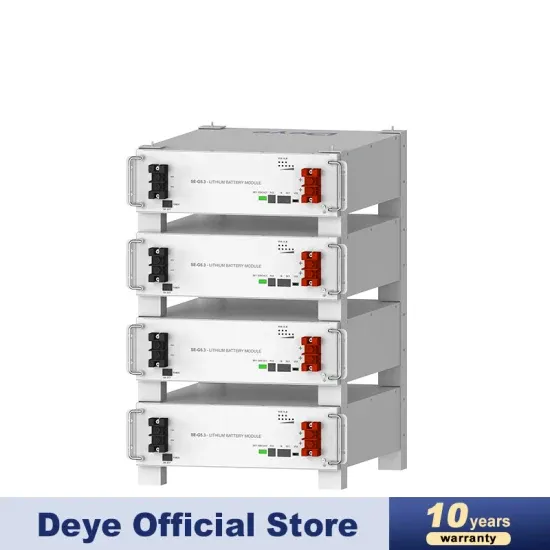

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.