What are the Key Steps and Precautions When Installing PV Combiner Boxes?

Aug 7, 2025 · Inspect the combiner box''s packaging and enclosure for any damage, and ensure the product certificate, accessories (such as terminals and screws), and user manual are

PV Combiner Box: Ultimate Guide 2025 & ETEK Solar Solutions

4 days ago · A solar combiner box (or photovoltaic combiner box) consolidates multiple strings of solar panels into a single main output circuit. It acts as the "traffic controller" of your solar

The Ultimate Guide to Solar Combiner Boxes:

Sep 26, 2024 · Solar combiner boxes are integral to solar power systems, serving to combine the outputs of multiple solar panel strings into a single output for

Photovoltaic combiner box installation standards

Combiner boxes play an important role in photovoltaic (PV) installations. This comprehensive guide aims to shed light on the importance, functions, types and best practices of combiner

Integrating a Photovoltaic Combiner Box: A Step-by-Step

May 10, 2024 · Conduct individual tests on each solar panel string to confirm that they are yielding the anticipated voltage and current levels. Validate the combiner box''s functionality by

What is a solar combiner box and why is it used

Mar 25, 2025 · Learn all about solar combiner boxes. Combiner boxes combine solar strings into a single power source for inverters, limiting energy loss and

什么是直流光伏太阳能汇流箱

太阳能汇流箱是指用户可以将一定数量的相同规格的光伏电池串联起来,形成单个的光伏串,然后将多个串并联成一个太阳能汇流箱。汇聚到太阳能汇流箱内

What is Combiner Box

2 days ago · A combiner box, also known as a junction box, is a crucial electrical enclosure widely applied in photovoltaic (PV) systems, electrical power distribution networks, and diverse

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · A combiner box, also known as a PV combiner box or solar combiner box, is an electrical enclosure that consolidates multiple strings of solar panels into a single output.

6 FAQs about [Photovoltaic combiner box confirmation]

What is a solar combiner box?

Solar combiner boxes are essential components in solar photovoltaic (PV) systems, designed to consolidate the outputs of multiple solar panel strings into a single output for connection to an inverter. There are various types of combiner boxes tailored to meet specific needs and configurations in solar installations. Here are the primary types:

What is a photovoltaic AC combiner box?

The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC output side of the inverter and the grid connection point/load. It is internally equipped with input circuit breakers, output circuit breakers, and AC lightning arresters.

Do you need a solar combiner box?

Adaptability: While smaller residential systems may not require a combiner box if they have only one to three strings, larger systems—ranging from four strings up to thousands—benefit greatly from their use. This adaptability makes combiner boxes suitable for both residential and commercial applications. II. Basics of PV Solar Combiner Boxes

Why do solar panels need a combination box?

Efficiency is the hallmark of any successful solar installation. Combiner boxes help improve the overall efficiency of the photovoltaic system by optimizing the wiring structure and integrating the DC output. Combiner boxes are designed to accommodate the inherent scalability and flexibility of solar installations.

Do solar combiner boxes have surge protection?

Given that solar installations are exposed to the outdoors, combiner boxes often include surge protection to protect the system from voltage spikes caused by lightning or other electrical disturbances. To prevent overcurrent conditions and protect wiring and components, combiner boxes are equipped with fuses or circuit breakers.

Why is a combination box important in a solar system?

In a vast solar system, each element plays a vital role in ensuring optimal performance and efficiency. Combiner boxes play an important role in photovoltaic (PV) installations.

Learn More

- Photovoltaic combiner box heating

- Malaysia Photovoltaic Combiner Box

- Danish 1500vdc photovoltaic combiner box

- Photovoltaic combiner box DC cabinet

- Energy storage photovoltaic combiner box price

- Photovoltaic combiner box for sale

- Eritrea Photovoltaic Combiner Box

- Nepal photovoltaic power generation combiner box recommendation

- Brussels photovoltaic combiner box manufacturer

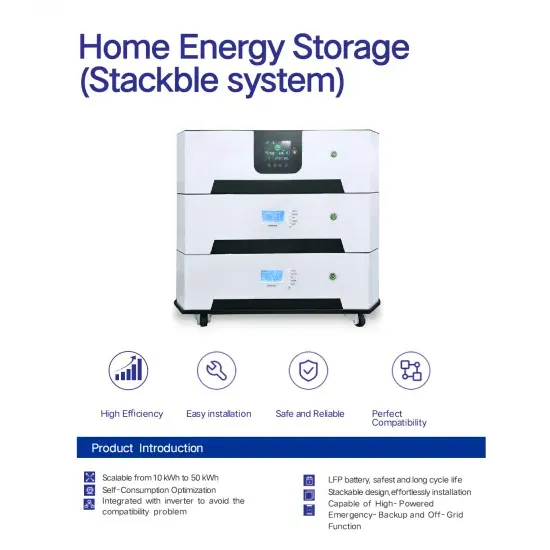

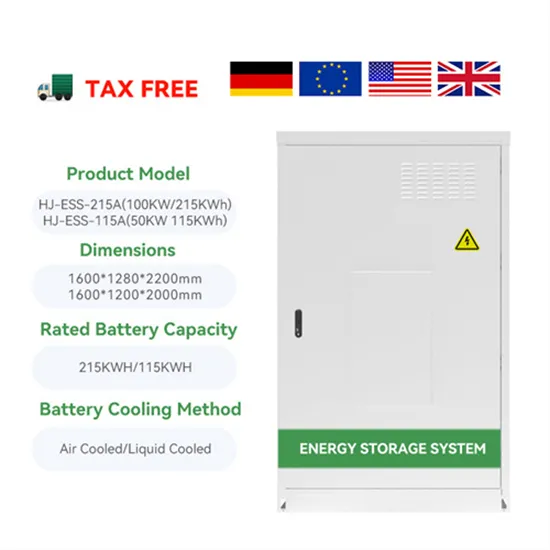

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.