3. System design and BMS selection guide

Mar 17, 2025 · This chapter describes things to consider on how the battery interacts with the BMS and how the BMS interacts with loads and chargers to keep the battery protected. This

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · In the world of lithium-ion batteries, the term "BMS battery" has become increasingly common — especially among manufacturers, engineers, and consumers of

What is a Battery Management System (BMS)? –

1 day ago · Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · It is an electronic control unit that monitors, manages, and protects rechargeable batteries, especially lithium-ion battery packs. When we refer to a BMS battery, we''re typically

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Resetting the Balance: How to Reset a Lithium Battery BMS

Jun 19, 2025 · One important component in the lithium battery system is the Battery Management System (BMS). The BMS helps regulate and balance charge levels in individual cells of the

What is Battery Management System (BMS)?

Dec 3, 2024 · A battery management system, or BMS for short, is an electrical system that regulates and maintains a battery''s performance. By regulating several factors, including

What is a Battery Management System? Complete Guide to BMS

Aug 3, 2025 · A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs to ensure safe operation, optimal performance, and

Understanding Battery Management Systems (BMS):

Jan 18, 2025 · Explore how Battery Management Systems (BMS) optimize battery performance, ensure safety, and enable efficient energy storage. Learn about key features, architectures,

Battery BMS: Understanding the Basics and its Importance

Understanding the basics of a Battery BMS is essential for anyone working with batteries or considering implementing them into their operations. The components of a Battery BMS work

What Does BMS Mean in Lithium Batteries?

Dec 19, 2024 · What does BMS mean in lithium batteries? Learn how a Battery Management System ensures safety, extends battery life, and powers electric vehicles and energy storage

3 FAQs about [BMS on the battery]

What is battery management system (BMS)?

Furthermore, this course will solely be focused on Battery management systems (BMS). The module will focus on string balancing within battery packs, the theory and algorithms, and use simulation-based software such as MATLAB/Simulink or Octave for algorithms and designing and simulation of cell equivalent circuits.

How do you classify a battery management system (BMS)?

While there are many methods to categorize BMSs, today, we’ll classify them based on how they are installed and operate on the cells or modules across the battery pack. Centralized BMS Architecture: This architecture is characterized by one central BMS in the battery pack assembly that all the battery packages are connected to.

How does a BMS protect a battery pack?

Most importantly, a BMS must protect each cell of the pack from getting overcharged or deep discharged. A battery pack might consist of multiple cells, arranged in different ways. When you connect multiple cells in series, you increase the output voltage of the pack.

Learn More

- Disadvantages of lithium battery BMS

- BMS battery management system voltage

- Battery BMS Layout Plan

- San Marino BMS battery management control system manufacturer

- North Africa BMS lithium battery manufacturers

- Russian BMS battery management

- BMS component installation structure of battery module

- Bogota lithium battery bms module

- BAIC Battery Management System BMS

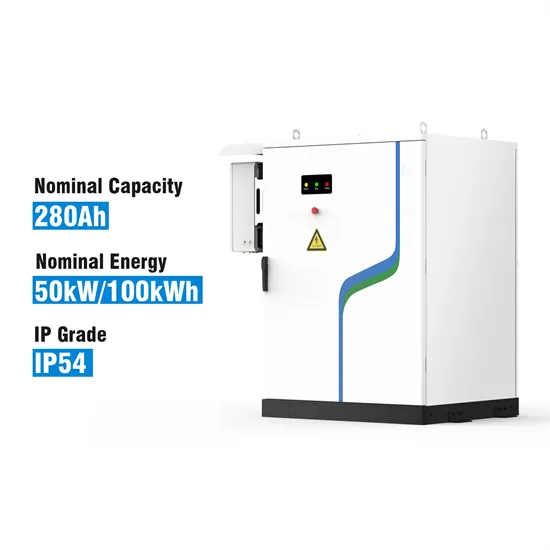

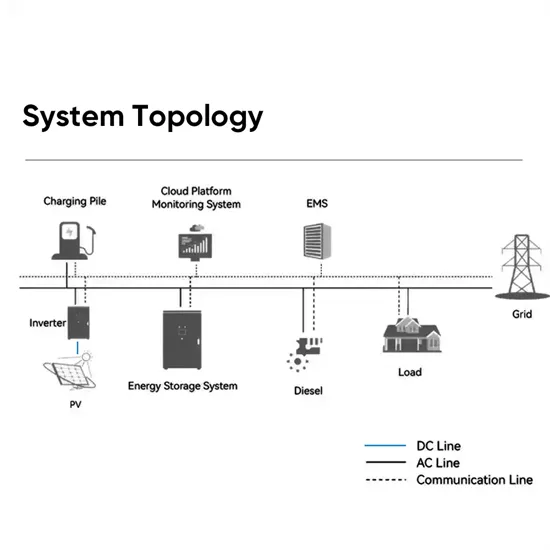

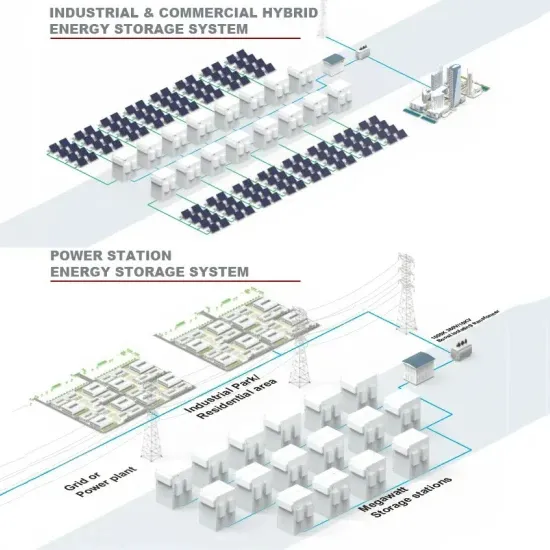

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.