Designing a BESS Container: A Comprehensive Guide to Battery

Apr 10, 2023 · Discover the essential steps in designing a containerized Battery Energy Storage System (BESS), from selecting the right battery technology and system architecture to

Stora How to design a BMS, the brain of a battery

Dec 3, 2021 · Every modern battery needs a battery management system (BMS), which is a combination of electronics and software, and acts as the brain of the battery. This article

电池管理系统(BMS)架构详细解析:原理与器件选型指南

Dec 6, 2024 · BMS(电池管理系统)架构详细讲解 从你提供的BMS(Battery Management System)架构图来看,主要涉及到电池监控模块、通信模块、功率控制模块等部分。下面我

Basics of battery management system (BMS) and key points for battery

Dec 17, 2024 · A Battery Management System (BMS) is an essential component within a battery-powered system that ensures safe and efficient operation. Its primary function is to monitor

A Comprehensive Roadmap for Successful Battery Energy

Jun 10, 2025 · An advanced EMS integrates data from the Battery Management System (BMS) to monitor key operational parameters, including state of charge, temperature, voltage, and state

48V LiFePO4 Battery System Deep Dive: BMS Architecture,

Jul 24, 2025 · In-depth look at 48v lifepo4 battery system—BMS design, temp sensors, cooling, and wiring tips to optimize performance for golf carts and RVs.

Battery Management System (BMS): Diagrams & IC Selection

Aug 19, 2025 · Battery Management System (BMS) explained: key functions, block/circuit diagrams (PDF), LiFePO4 notes, 12V/24V/3S cases, and cross-brand IC choices with price

Why Do Lithium Batteries Use Three Wires and What Does

5 hours ago · Lithium battery wiring uses three wires for power and monitoring. Each wire ensures safety, proper charging, and protection with or without a BMS.

Battery Management System (BMS) Architecture:

Oct 14, 2024 · The Battery Management System (BMS) is a crucial component in ensuring the safe and efficient operation of lithium-ion battery packs in electric

Basics of battery management system (BMS), battery pack

Dec 16, 2024 · A Battery Management System, or BMS, is an essential component in many modern electronic devices, especially those reliant on rechargeable batteries. These include

An end-to-end approach to Design and Verify BMS:

May 27, 2025 · A BMS for a battery pack is typically composed of: 1)Battery Management Unit (BMU) Centralized control of battery pack. Includes state estimation (SoC, SoH, SoX).

Battery management system and battery disconnect unit

The battery management system and electronical battery disconnect unit consist of several components designed to monitor, manage, control, and disconnect the battery cells of a

Port Dundas BESS – Outline Battery Storage Safety

Apr 4, 2025 · 1.1 Scope The purpose of this document, the Port Dundas Outline Battery Storage Safety Management Plan (OBSSMP), is to describe the guidelines and best practice for safe

Stora How to design a BMS, the brain of a battery

Dec 3, 2021 · How to design a BMS, the brain of a battery storage system nding market conditions, providing a wide range of applications. Christoph Birkl, Damien Frost and Adrien

如何设计电池管理系统 (BMS)| 文章 | MPS

结语 BMS 监测电池组以保护电池和系统的其余部分。 设计不当的 BMS 不仅会降低系统的安全性,而且还导致不准确的电池 SOC 管理。 这种不准确对产品的

Battery Management System Reference Design

Jun 6, 2022 · The Altera® Battery Management System (BMS) Reference Design demonstrates battery state of charge (SOC) estimation in an FPGA-based real-time control platform that you

6 FAQs about [Battery BMS Layout Plan]

What is a battery management system (BMS)?

The battery management system (BMS) monitors the battery and possible fault conditions, preventing the battery from situations in which it can degrade, fade in capacity, or even potentially harm the user or surrounding environment.

What are the building blocks of a battery management system?

Figure 1. A Simplified Diagram of the Building Blocks of a Battery Management System A battery management system can be comprised of many functional blocks including: cutoff FETs, a fuel gauge monitor, cell voltage monitor, cell voltage balance, real time clock (RTC), temperature monitors and a state machine.

What is modular battery management system architecture?

Modular Battery Management System Architecture Modular battery management system architecture involves dividing BMS functions into separate modules or sub-systems, each serving a specific purpose. These modules can be standardized and easily integrated into various battery systems, allowing for customization and flexibility.

What is battery management system architecture?

The battery management system architecture is a sophisticated electronic system designed to monitor, manage, and protect batteries. It acts as a vigilant overseer, constantly assessing essential battery parameters like voltage, current, and temperature to enhance battery performance and guarantee safety.

What is centralized battery management system architecture?

Centralized battery management system architecture involves integrating all BMS functions into a single unit, typically located in a centralized control room. This approach offers a streamlined and straightforward design, where all components and functionalities are consolidated into a cohesive system. Advantages:

What is a battery management system (BMU)?

As the vigilant eyes and ears of the BMS, the BMU ensures real-time monitoring of the battery’s condition and performance. Accurate data collection by the BMU is of paramount importance for effective battery management.

Learn More

Industrial & Commercial Energy Storage Market Growth

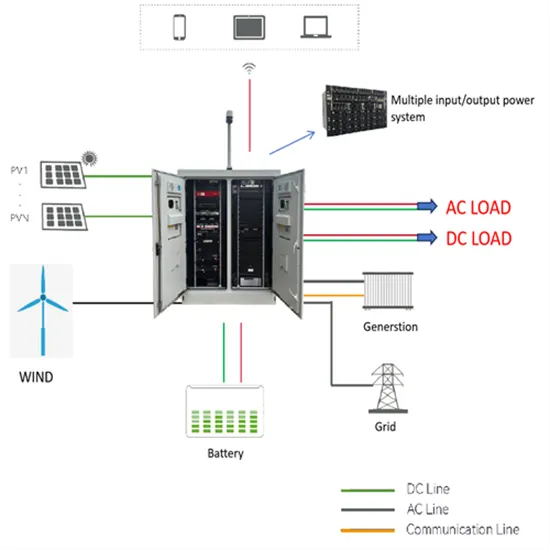

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

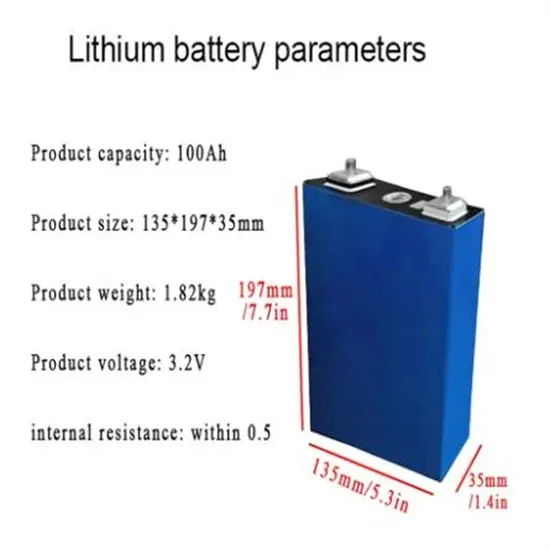

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.