Hydrated eutectic electrolyte as catholyte enables high

Apr 20, 2024 · Furthermore, the battery could stably cycle over 120 cycles with a capacity retention of 87.75 % at a relatively high current density of 10 mA cm −2, delivering a maximum

Novel Aluminum-Ion Based Non-Aqueous Redox Flow Battery

Oct 19, 2021 · In this regard, an aluminum-ion-based non-aqueous redox flow battery was introduced in this study as a proof-of-concept. The aluminum redox ion is used as negolyte

UNM startup to market aluminum-based batteries

Oct 3, 2023 · For one thing, Flow Aluminum''s product would avoid the need for rare Earth minerals used in lithium-ion batteries, which face chronic supply constraints and environmental

Deep eutectic solvent for high-performance aluminum-based

Nov 1, 2024 · Aqueous multivalent ion batteries, featured by cost-effectiveness, high safety and eco-friendliness, are considered as a preferred alternative to non-aqueous multivalent ion

An overview and prospective on Al and Al-ion battery technologies

Jan 1, 2021 · Aluminum batteries are considered compelling electrochemical energy storage systems because of the natural abundance of aluminum, the high charge storage capacity of

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · The advent of flow-based lithium-ion, organic redox-active materials, metal–air cells and photoelectrochemical batteries promises new opportunities for advanced electrical energy

Advancing Flow Batteries: High Energy Density

Dec 17, 2024 · A high-capacity-density (635.1 mAh g − ¹) aqueous flow battery with ultrafast charging (<5 mins) is achieved through room-temperature liquid

A Low-Cost and High-Energy Hybrid Iron-Aluminum Liquid Battery

Nov 15, 2017 · Here, an all-DES-based liquid battery is proposed with an ultrahigh concentration of redox species, resulting in high energy density. The DES maintains reduced lattice energy

A low-cost all-iron hybrid redox flow batteries enabled by

Jul 1, 2024 · Nevertheless, the high cost of vanadium metal hinders the continued commercialization of vanadium redox flow batteries (VRFBs), prompting the exploration of low

Electrolyte design for rechargeable aluminum-ion batteries:

Nov 1, 2023 · For aluminum-based electrolytes, the high surface charge density of aluminum ions results in strong Coulombic interactions between aluminum salt cations and anions, leading to

A Sustainable Redox-Flow Battery with an Aluminum-Based,

Jun 19, 2017 · Redox flow batteries (RFBs), which store chemical energy in fluids, are a promising option but their anolytes — the conductive fluid, or electrolyte, at the positively charged end of

High performance aluminum-air flow batteries through

Jan 1, 2024 · The practical performance of as-prepared samples was investigated using a battery testing system by a self-made double-face flow Al-air battery (DFAB) system, which contained

A Sustainable Redox‐Flow Battery with an

Sep 29, 2017 · Abstract: Nonaqueous redox flow batteries are an emerging energy storage technology for grid storage systems, but the development of anolyte has lagged far behind the

New Startup Flow Aluminum Developing Low Cost, Aluminum-Based Batteries

Oct 2, 2023 · A new startup company is working to develop aluminum-based, low-cost energy storage systems for electric vehicles and microgrids. Founded by University of New Mexico

Iron flies higher

Aug 2, 2021 · Organic materials have shown promise to meet some of the challenges of traditional metal-based flow battery electrolytes: for example, flow batteries with organic electrolytes

Next-Generation Liquid Metal Batteries Based on

Jul 9, 2020 · With a long cycle life, high rate capability, and facile cell fabrication, liquid metal batteries are regarded as a promising energy storage technology

Emerging chemistries and molecular designs for flow batteries

Jun 17, 2022 · From the zinc-bromide battery to the alkaline quinone flow battery, the evolution of RFBs mirrors the advancement of redox chemistry itself, from metal-centred reactions to

Designing modern aqueous batteries | Nature Reviews

Nov 15, 2022 · The emergence of new materials and cell designs is enabling the transition of aqueous batteries into competitive candidates for reliable and affordable energy storage. This

6 FAQs about [Aluminum-based flow battery]

How does a flow aluminum battery work?

An aluminum derivative also provides an additional catalyst to speed the process, and a liquid electrolyte — called an “ionic liquid” — efficiently moves the ions and electrons around in the battery. That electrochemical process allows Flow Aluminum batteries to store more energy and provide a powerful discharge of electricity.

Could flow aluminum compete with Ionic lithium-ion batteries?

A new startup company is working to develop aluminum-based, low-cost energy storage systems for electric vehicles and microgrids. Founded by University of New Mexico inventor Shuya Wei, Flow Aluminum, Inc. could directly compete with ionic lithium-ion batteries and provide a broad range of advantages.

What is flow aluminum?

Flow Aluminum Inc., founded in May 2023 in Albuquerque, develops advanced aluminum-CO₂ battery technology as a safe, cost-effective, and sustainable alternative to lithium-ion. Their high-performance, non-flammable batteries are used in electric vehicles, grid storage, and more, supporting the clean energy transition.

What are organic redox flow batteries?

Organic redox flow batteries (ORFBs) are another important category of RFBs, providing favorable energy storage environment to harness the power of organic compounds and appropriately release electrical energy as required.

Could flow aluminum make a battery 'open format'?

That could allow Flow Aluminum to develop to two different battery options, including a “sealed” system with all materials enclosed inside, or an “open format” whereby the battery stores and discharges electricity while also pulling carbon directly from the air, Fetrow said.

How to adjust the power and energy capacity of flow batteries?

The power and energy capacity of flow batteries can be adjusted by adjusting the storage of liquid electrolyte, which also helps in adjusting the overall efficiency of the system. Both the power density and energy capacity are also independent in flow battery systems.

Learn More

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- Flow battery skills and applications

- Zinc manganese dioxide flow battery

- Which type of flow battery is better

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Flow battery manufacturing equipment price

- Flow battery electrode saturation

- 1gw all-vanadium liquid flow battery energy storage

- Polypropylene flow battery

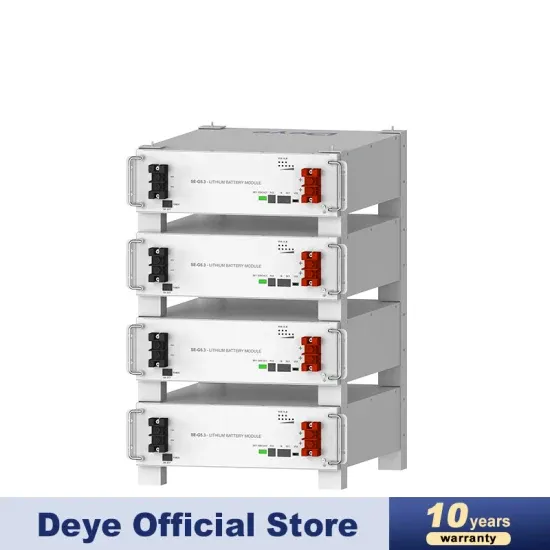

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

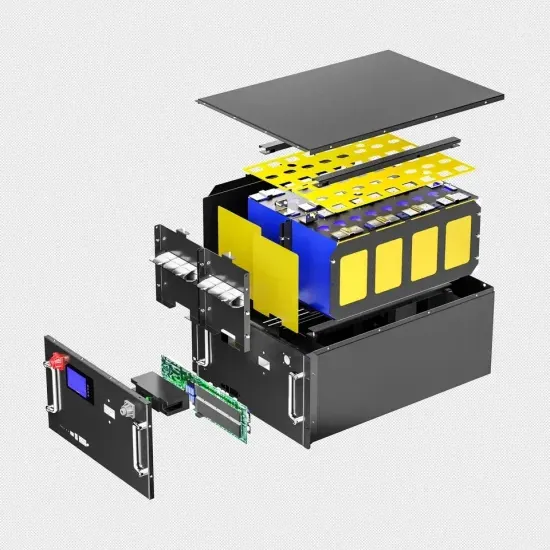

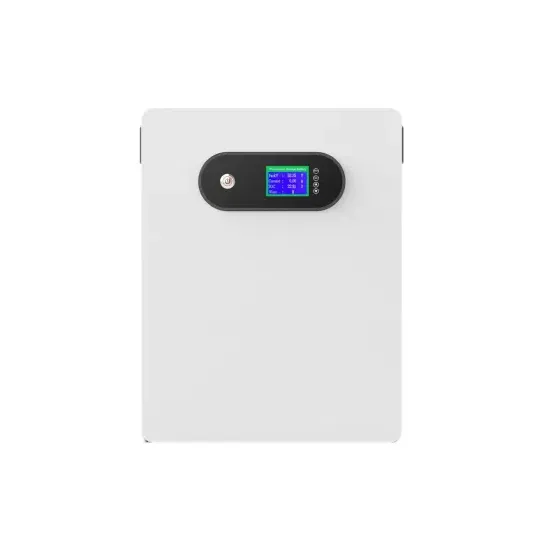

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.