Wetting characteristics of Li-ion battery electrodes: Impact of

Jun 1, 2024 · Calendaring is a common process for enhancing the power density of Li-ion battery electrodes. In this study, the Shan-Chen-based Lattice Boltzmann Method is used to

Synchrotron X-ray Radiography and Tomography of Vanadium Redox Flow

Apr 14, 2020 · The wetting behavior and affinity to side reactions of carbon-based electrodes in vanadium redox flow batteries (VRFBs) are highly dependent on the physical and chemical

Visualization of electrolyte flow in vanadium redox flow batteries

Nov 1, 2019 · The electrolyte distribution inside the porous electrodes of vanadium redox flow batteries is critical to the performance, as it determines the electrochemically active surface

Electrode materials for vanadium redox flow batteries:

Jan 1, 2022 · Vanadium redox flow battery (VRFB) is considered to be one of the most promising renewable energy storage devices. Although the first generation of VR

Understanding Electrolyte Filling of Lithium‐Ion Battery

Oct 11, 2022 · More-over, only 2D simulations were conducted, although this reduces the number of flow paths significantly and thereby strongly affects the saturation behavior, pore blocking,

Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · These novel electrode structures (dual-layer, dual-diameter, and hierarchical structure) open new avenues to develop ECF electrodes that can considerably improve the

Recent understanding on pore scale mass transfer phenomena of flow

Feb 1, 2025 · The performance of flow batteries is critically influenced by mass, ion, and electron transport processes and electrochemical reactions within the heterogenous porous electrodes.

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Spatial separation of the electrolyte and electrode is the main characteristic of flow-battery technologies, which liberates them from the constraints of overall energy content and

Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · Finally, the scientific challenges and prospects of electrospun carbon fiber electrodes with maximized specific surface areas and hydraulic permeability are presented.

Data-driven macro-scale simulation for rapid electrolyte

Jan 15, 2025 · This presents a significant challenge for the back-end processes of electrode manufacturing, particularly the electrolyte wetting process. As the battery manufacturing

Fundamental models for flow batteries

Aug 1, 2015 · The flow battery is a promising technology for large-scale storage of intermittent power generated from solar and wind farms owing to its unique advantages such as location

A comprehensive review on flow-electrode capacitive

Jan 15, 2022 · Nevertheless, in a fixed-electrode CDI cell, because the amounts of active electrodes are limited by the size of the current collector, the deionization capacity of the CDI

A tungsten polyoxometalate mediated aqueous redox flow battery

May 19, 2025 · The in-situ CV and electrode potential measurements were carried out using a modified device of flow cell, placed with a Ag/AgCl (saturated KCl) electrode worked as

High-performance Porous Electrodes for Flow

Oct 2, 2024 · Porous electrodes are critical in determining the power density and energy efficiency of redox flow batteries. These electrodes serve as platforms

A tungsten polyoxometalate mediated aqueous redox flow battery

May 19, 2025 · Based on the cyclic pH change and self-regulation process of 3Na-PW 12 in the charge and discharge process, the aqueous flow battery offered a high-power density of 200

Understanding wetting behavior in electrode–electrolyte

May 7, 2024 · The formation of the electrolyte–electrode interface is essential for the performance of Li-ion batteries. This study aims to explore the wetting characteristics of an electrolyte within

Lattice Boltzmann Simulation of Flow, Transport, and

Apr 3, 2024 · More specifically, two-phase flow, Darcy-Brinkman-type homogenization, electrolyte filling and gas entrapment in lithium-ion battery electrodes as well as surface reactions and

A gas-liquid slip flow model for predicting bubble

Under normal operation, the liquid electrolyte in porous electrodes of flow batteries typically maintains high saturation levels, generally exceeding 70 %, and exists as a continuous phase.

Understanding Electrolyte Filling of Lithium‐Ion

Mar 1, 2022 · Electrolyte filling is a time‐critical step during battery manufacturing that also affects battery performance. The underlying physical phenomena

High-performance Porous Electrodes for Flow Batteries:

Nov 7, 2024 · Electrodes, which offer sites for mass transfer and redox reactions, play a crucial role in determining the energy efficiencies and power densities of redox flow batteries.

Enhancing electrode wettability in lithium-ion battery via

Mar 1, 2021 · Enhancing the electrolyte wetting has been claimed to be a great challenge in developing high-energy density and large-scale lithium-ion batteries (LI

Soft–hard zwitterionic additives for aqueous halide flow batteries

Oct 23, 2024 · Zwitterionic additives composed of a ''soft'' organic cation and a ''hard'' anion enable homogeneous halide cycling in aqueous halide redox flow batteries, resulting in improved

Increased electrolyte flow resistance and blockage due to

Feb 1, 2025 · Under the interaction between gas bubbles and liquid flow, hydrogen evolution reactions at the scale of "mA cm -2 " significantly reduce the electrolyte flow through the

Mass transfer in flow batteries characterized by comparison

Nov 15, 2022 · In this study, we introduce a segmented cell that can measure the electrochemical reaction kinetics occurring in a porous electrode for a vanadium redox flow battery in real time.

Understanding Electrolyte Filling of Lithium-Ion Battery

Jul 8, 2022 · More-over, only 2D simulations were conducted, although this reduces the number of flow paths significantly and thereby strongly affects the saturation behavior, pore blocking, gas

6 FAQs about [Flow battery electrode saturation]

Why are porous electrodes important in redox flow batteries?

See all authors Porous electrodes are critical in determining the power density and energy efficiency of redox flow batteries. These electrodes serve as platforms for mesoscopic flow, microscopic ion diffusion, and interfacial electrochemical reactions.

Can ECF electrodes be used for redox flow batteries?

The application of ECF electrodes to redox flow batteries started in the early 2010s with the study of the electrochemical activity of ECFs towards the vanadium redox couples.

Why are flow batteries regarded as a promising large-scale energy storage technology?

7. Concluding remarks and perspectives Flow batteries are regarded as one of the most promising large-scale energy storage technologies because of their site-independency, decoupling of power and energy, design flexibility, long cycle life, and high safety.

What is a redox flow battery?

Schematic of a redox flow battery. As a key component of RFBs, electrodes play a crucial role in determining the battery performance and system cost, as the electrodes not only offer electroactive sites for electrochemical reactions but also provide pathways for electron, ion, and mass transport [28, 29].

Can ECF electrodes improve battery performance?

These novel electrode structures (dual-layer, dual-diameter, and hierarchical structure) open new avenues to develop ECF electrodes that can considerably improve the battery performance and demonstrate the superiority in fabricating electrodes with desired properties for next-generation flow battery electrodes. Fig. 12.

Do flow batteries need a high permeability?

However, the electrodes for flow batteries need to be highly permeable for electrolyte transport. According to Carman-Kozeny equation (K = d f 2 ε 3 16 K c k (1 − ε) 2), the fiber diameter needs to as large as possible to achieve a high permeability of ECFs.

Learn More

- Communication base station flow battery detector

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Is flow battery a new energy source

- Communication base station flow battery technology and management

- Iron-based liquid flow battery energy storage system

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- Flow Battery 2025

- 1gw all-vanadium liquid flow battery energy storage

- Nigeria s new all-vanadium flow battery

Industrial & Commercial Energy Storage Market Growth

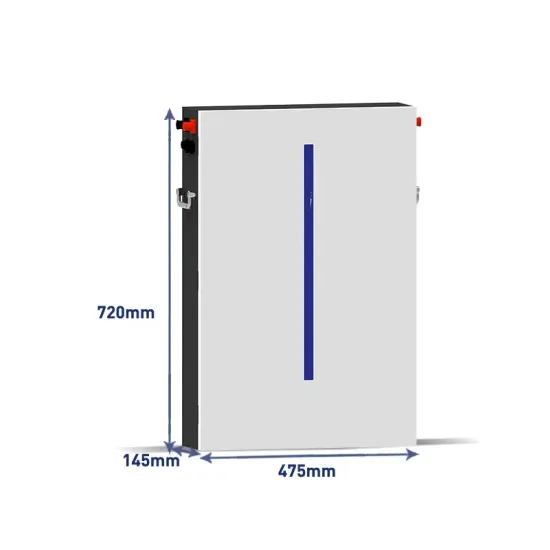

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.