A promising assembled electrode-bipolar plate for redox flow battery

Sep 10, 2024 · As the importance of redox flow battery (RFB) attracts wide attention due to the demand for large-scale energy storage, relative revolution to reduce the costs and increase

A review of bipolar plate materials and flow field designs in

Apr 1, 2022 · A bipolar plate (BP) is an essential and multifunctional component of the all-vanadium redox flow battery (VRFB). BP facilitates several functions in

Perfect capacity retention of all-vanadium redox flow battery

May 25, 2023 · Abstract Crossover of vanadium ions through proton conducting membranes in all-vanadium redox flow batteries (VRFBs) causes considerable engineering problems and

Battery or DC Powered Plastic Body Electromagnetic Flow Meter

Dec 28, 2017 · The FMG800 Series is a full-bore, plastic-bodied electromagnetic flow meter designed for flow and usage monitoring applications in 1, 2 and 3 inch pipe. The polypropylene

Flow battery production: Materials selection and

Oct 1, 2020 · Production of zinc-bromine flow batteries had the lowest values for ozone depletion, and freshwater ecotoxicity, and the highest value for abiotic resource depletion. The analysis

Chapter Key Components in the Redox-Flow Battery:

Nov 8, 2021 · Abstract Graphite filled thermoplastic based composites are an adequate material for bipolar plates in redox flow battery applications. Unlike metals, composite plates can

A promising assembled electrode-bipolar plate for redox flow battery

Sep 10, 2024 · This study proposes an adhesive conducting layer composed of polypropylene (PP) and carbon felt fiber to connect two carbon felt, thus fabricating assembled electrode

Technology: Flow Battery

Nov 4, 2024 · A flow battery is an electrochemical battery, which uses liquid electrolytes stored in two tanks as its active energy storage component. For charging and discharging, these are

Strategy towards high ion selectivity membranes for all

Nov 25, 2023 · Vanadium redox flow batteries (VRFBs) have become the most promising and commercially exploited flow batteries among the range of technical solutions for stationary

Corrosion of Graphite-Polypropylene Current Collectors

Apr 4, 2018 · Graphite-polypropylene bipolar plates (BPP) were subjected to galvanostatic treatment in highly charged positive and negative vanadium electrolyte solutions. The tests

Perfect capacity retention of all-vanadium redox flow battery

May 25, 2023 · Crossover of vanadium ions through proton conducting membranes in all-vanadium redox flow batteries (VRFBs) causes considerable engineering problems and

Polypropylene elastomer composite for the all-vanadium

Dec 3, 2014 · In this study, a carbon-based polypropylene thermoplastic elastomer (PP-elastomer) composite for current collectors of an all-vanadium redox flow battery (VRB) was

A green europium-cerium redox flow battery with ultrahigh

Nov 15, 2024 · However, the main redox flow batteries like iron-chromium or all-vanadium flow batteries have the dilemma of low voltage and toxic active elements. In this study, a green Eu

(Journal of Materials Chemistry A) Polypropylene

In this study, carbon-based polypropylene thermoplastic elastomer (PP-elastomer) composite for current collectors of all-vanadium redox flow battery (VRB) was successfully prepared. The

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for

用于高性能、高容量保留全钒氧化还原液流电池的坚固聚苯胺

Mar 4, 2024 · Robust Polyaniline-silica@polypropylene for High-Performance, High-Capacity Retention All-Vanadium Redox Flow Battery The development of high-performance

Polypropylene elastomer composite for the all-vanadium redox flow

Jan 20, 2015 · In this study, a carbon-based polypropylene thermoplastic elastomer (PP-elastomer) composite for current collectors of an all-vanadium redox flow battery (VRB) was

Zinc–iron (Zn–Fe) redox flow battery single to stack cells: a

Abstract The decoupling nature of energy and power of redox flow batteries makes them an efficient energy storage solution for sustainable off-grid applications. Recently, aqueous

6 FAQs about [Polypropylene flow battery]

Which materials can be used in flow batteries?

Large quantities of active materials are needed to store the generated energy in grid-scale EES systems. Vanadium and lithium metals are not abundant resources, and therefore sodium and zinc are being considered as alternative materials for use in flow batteries.

Can electrode-bipolar plate reduce resistance of redox flow battery?

As the importance of redox flow battery (RFB) attracts wide attention due to the demand for large-scale energy storage, relative revolution to reduce the costs and increase the efficiencies of RFB has been in full swing. Assembled electrode-bipolar plate is considered a promising and economical method to decrease the resistance.

Are flow-battery technologies a future of energy storage?

Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for next-generation flow batteries.

How are redox flow batteries prepared?

The AEBPs subjected to the three-pack redox flow batteries were prepared with PP 4# and 50 % CFF under an 18 % compression ratio. In contrast, a three-pack redox flow battery was operated with the traditional composite bipolar plate. The electrochemistry results of the batteries are presented in Fig. 7.

What is a stack-type flow battery?

A stack-type flow battery, similar in configuration to conventional fuel cells, is probably the design that is most closely approaching commercial applicability. The main components of the stack cell are the negative and positive electrodes, bipolar plates, current collectors and membranes.

What is vanadium redox flow battery technology?

Vanadium redox flow battery technology utilises two electrolyte solutions that are pumped into a twin chamber tank via two separate independent flow lines. These positive (anolyte) and negative (catholyte) electrolytes typically contain a chemical solution with sulphuric acid at around 30% concentration.

Learn More

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- Flow battery skills and applications

- Is flow battery a new energy source

- Zinc manganese dioxide flow battery

- Which type of flow battery is better

- Communication base station flow battery technology and management

- Iron-based liquid flow battery energy storage system

- Flow battery manufacturing equipment price

- 50mw all-vanadium liquid flow battery energy storage power station

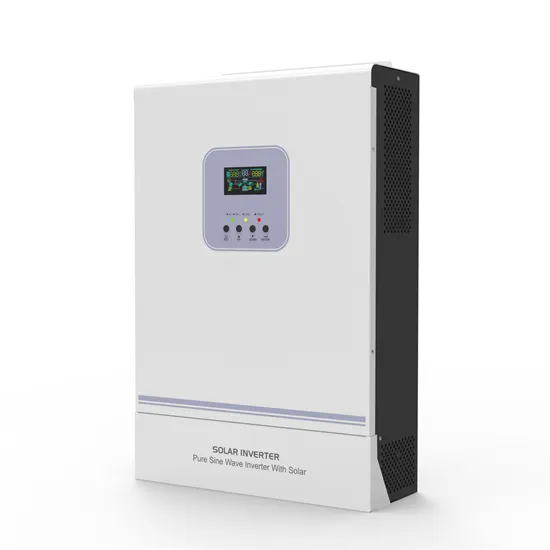

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.