Selecting and Applying Aluminum Electrolytic Capacitors

Aug 26, 2021 · Abstract— Aluminum electrolytic capacitors are widely used in all types of inverter power systems, from variable-speed drives to welders to UPS units. This paper discusses the

LCL Filter Design for Grid Connected Three-Phase Inverter

Feb 22, 2024 · Abstract— In this study, LCL filter design was performed by simulating and theoretical analysis detail of a grid-connected system in MATLAB / Simulink environment.

Design Capacitors for Applications | DigiKey

May 13, 2016 · The importance of dielectric materials, ESR, ripple current and other parameters when selecting DC link capacitors for maximum performance in DC link circuits.

Full_Paper_English_Format_3.doc

Sep 26, 2016 · Now the rms-current in the dc-link capacitors is analytically calculated for sine wave output currents with arbitrary phase shift angles f P1 and modulation factors m. For this

DC Link Capacitors Selection and Arrangement Procedure in

Dec 28, 2023 · The most important parasitic elements in high-power inverters are the ones associated with the DC-link and the capacitors used in its structure. This article will describe

Inverter DC Link Capacitor Selection

Sep 10, 2019 · Properly sizing the DC link capacitor for a three phase inverter seems to be a skill that evades most power electronic engineers. The objective of this article is to help you better

Comprehensive Analysis for DC-Link Capacitor Sizing for a Three-Phase

May 13, 2022 · An analytical approach to size a dc-link capacitor for a three-phase current-controlled voltage-source inverter used for a permanent magnet synchronous motor is

Selecting and Applying DC Link Bus Capacitors

Aug 15, 2025 · For three-phase inverters at any DC bus voltage, for films and electrolytics, respectively, a rule of thumb is that about 5 and 50 millicoulombs of capacitor nameplate CV

Selection and calculation of dclink capacitor in

electrolytic DC-Link capacitors. How do I choose a DC-link capacitor? Other considerations in choosing a DC-Link capacitor include knowing the DC voltage required at the rails, the

DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

Microsoft PowerPoint

Jan 28, 2022 · Three phase inductors and capacitors form the low pass filters. Resonant filters are specifically designed (inductance and capacitance) to "tune" out the harmonic frequencies.

Selecting and Applying Aluminum Electrolytic Capacitors

Jun 23, 2023 · Abstract— Aluminum electrolytic capacitors are widely used in all types of inverter power systems, from variable-speed drives to welders to UPS units. This paper discusses the

How to Size Capacitors for 3-Phase Generator Conversion?

Sizing capacitors for a 3-phase motor-to-generator conversion requires careful calculations based on the motor''s power rating, voltage, power factor, and other parameters. By following the

How to Size & Arrange DC-Link Capacitors in a 3

Feb 27, 2025 · In a 100 kW, 3-phase Voltage Source Inverter (VSI) drive, the DC-link plays a crucial role in providing a stable voltage for the inverter stage. But

TIDA-01606: DC-Link Capacitor Calculation

Jan 26, 2022 · Part Number: TIDA-01606 Hello! I''m using TIDA-01606 as a reference for a three-phase inverter design. What I''d like to know is how did you calculate the required capacitance

Comprehensive Analysis for DC-Link Capacitor Sizing for a Three-Phase

May 13, 2022 · An analytical approach to size a dc-link capacitor for a three-phase current-controlled voltage-source inverter used for a permanent magnet synchronous motor is

Selecting Film Capacitors for Power Applications

May 8, 2025 · Understanding the structure and characteristics of film capacitors helps select the correct device to match specific power application requirements.

Selecting and Applying DC Link Bus Capacitors for

Oct 15, 2021 · For three-phase inverters at any DC bus voltage, for films and electrolytics, respectively, a rule of thumb is that about 5 and 50 millicoulombs of capacitor nameplate CV

Selecting Filter Capacitors for Three Phase Bridge Rectifiers

Jul 1, 2010 · Almost all off line switching power supplies over several kilowatts of output power use a three phase bridge rectifier. Typically, it comprises a six diode bridge and a DC bus filter

A DC bus capacitor design method for various inverter

Sep 20, 2012 · This paper involves the selection and sizing of the appropriate type of dc bus capacitor for various applications utilizing PWM operated three-phase voltage source

Analytical and calculation DC-link capacitor of a three-phase

Jun 7, 2018 · This paper proposes a three-phase photovoltaic inverter connected to a grid with a low DC link film capacitance. Generally, photovoltaic three-phase inverters have large

Selecting Capacitors for Inverter Applications

This paper has presented a discussion on how to properly size a bus link capacitor for a high performance hard switched DC to AC inverter using film capacitors and has shown that film

6 FAQs about [How to choose capacitors for three-phase inverters]

How much capacitor nameplate CV rating should a 3 phase inverter use?

For three-phase inverters at any DC bus voltage, for films and electrolytics, respectively, a rule of thumb is that about 5 and 50 millicoulombs of capacitor nameplate CV rating will be required per amp of ripple current.

How do I choose the right capacitor for my inverter?

In practice, selecting the right capacitor for your inverter involves more than just calculating the required capacitance. Other factors to consider include: - Voltage Rating: The capacitor must have a voltage rating higher than the DC link voltage to prevent breakdown.

How do I choose a DC-link capacitor?

Other considerations in choosing a DC-Link capacitor include knowing the DC voltage required at the rails, the expected life of the application, the maximum possible ripple current and frequency that the system will experience, and whether the generated ripple current is steady-state or intermittent.

How to sizing capacitors for inverter bus link applications?

The first step in sizing capacitors for inverter bus link applications should be to understand how much bus link capacitance is required for a given inverter design. The biggest design limitation for electrolytic capacitors in inverter applications has been the amount of ripple current that the electrolytic capacitor can sustain.

Does Adding capacitance improve the performance of an inverter?

So beyond a certain point, adding capacitance does little to enhance the performance of the inverter. = 308 uF That’s 16 times less capacitance than that of the electrolytic capacitor! Certainly packaging a 308 uF capacitor verses a 5,000uF capacitor makes for a smaller, lighter and more compact design.

Why does a DC link capacitor have a ripple current ICAP?

We may infer from Figure 2 that the DC link capacitor’s AC ripple current Icap arises from two main contributors: (1) the incoming current from the energy source and (2) the current drawn by the inverter. Capacitors cannot pass DC current; thus, DC current only flows from the source to the inverter, bypassing the capacitor.

Learn More

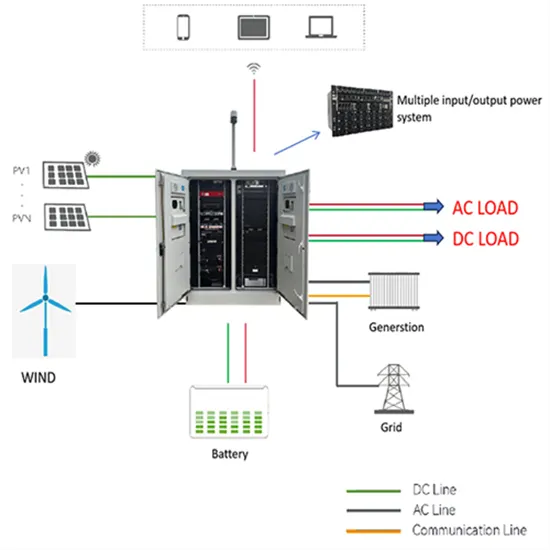

- How to connect photovoltaic inverters in series

- How to choose the main incoming wind power of UPS battery cabinet

- How to choose photovoltaic panel power

- What specifications should I choose for home inverters

- How to choose a manufacturer to install photovoltaic panels on the roof

- How do customers choose home energy storage batteries

- Two three-phase inverters

- The role of DC capacitors in grid-connected inverters

- How many capacitors are generally used in 5g base stations

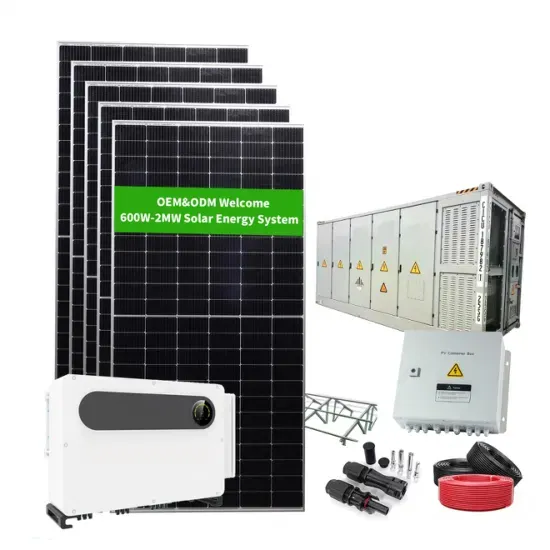

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.