Review of DC Offset Compensation Techniques for Grid

1. INTRODUCTION Power quality is an essential issue for the combination of grid connected inverters. The issues identified to DC current injection in inverter based distributed generation

Design and implementation of a virtual capacitor based DC

Sep 1, 2019 · To solve these problems, this paper proposes a virtual-capacitor based DC current suppression control technique for grid-connected inverters, which has the advantages of fast

Virtual inertia extraction from a DC bus capacitor in a three−phase DC

Dec 1, 2024 · Where the frequency of grid is associated to the virtual frequency which is derived directly from DC capacitor voltage, thus, large level of inertia is extracted. The basic

Stability Studies on PV Grid-connected Inverters under Weak Grid

Jul 11, 2024 · The integration of photovoltaic (PV) systems into weak-grid environments presents unique challenges to the stability of grid-connected inverters. This review provides a

Grid Connected Inverter Reference Design (Rev. D)

May 11, 2022 · Grid Connected Inverter Reference Design Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU).

Grid-connected photovoltaic inverters: Grid codes,

Jan 1, 2024 · This paper provides a thorough examination of all most aspects concerning photovoltaic power plant grid connection, from grid codes to inverter topologies and control.

Selecting Capacitors for Inverter Applications

II. THE BUS LINK CAPACITOR''S ROLE The bus link capacitor is used in DC to AC inverters to decouple the effects of the inductance from the DC voltage source to the power bridge.

A Novel DC Capacitor Deficit Power Balancing Mechanism

Jan 9, 2025 · In grid-connected inverters, dc capacitors maintain the dc bus voltage to feed the grid''s regulated power. Nevertheless, the dc bus voltage influences the solar panel power

Reactive power compensation during the convergence of grid

Sep 1, 2024 · In a single-phase series compensator, there are two stages of power conversion. Firstly, it comprises of DC-DC boost converter then the output stage is DC-AC tie converter

Review of DC Offset Compensation Techniques for Grid Connected Inverters

Best practices for minimizing DC offset in grid-connected inverters are reviewed. Australian standards limit DC injection to 5mA or 0.5% of inverter output current. Transformerless

A Review of Grid-Connected Inverters and Control Methods

Feb 4, 2025 · In this article, a new grid-tied system is proposed for PV applications which consists of an improved flyback DC-DC converter and a new switched-capacitor (SC) based multilevel

Sebuah Kajian Pustaka:

Jan 11, 2024 · 1. INTRODUCTION Power quality is an essential issue for the combination of grid connected inverters. The issues identified to DC current injection in inverter based distributed

Selection and calculation of dclink capacitor in

Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic systems and needs effort to design a reliable and optimal size capacitor as its reliability is

Optimization Tool for Dc-Link Capacitor Bank Design in PV Inverters

May 30, 2019 · The development of a tool is presented for optimizing dc-link capacitors design in PV inverters. Reliability of power converters is well known to be one of the bottlenecks for

A Novel DC Capacitor Deficit Power Balancing Mechanism

Jan 9, 2025 · In grid-connected inverters, dc capacitors maintain the dc bus voltage to feed the grid''s regulated power. Nevertheless, the dc bus voltage influences the solar

Bidirectional buck–boost converter‐based active power

Feb 14, 2025 · To address this issue, this paper introduces a power decoupling method. This method utilizes a bidirectional buck–boost converter, connected in parallel to the DC link, to

The role of DC capacitors in photovoltaic inverters

This study proposed a general method for sizing a dc-link capacitor for a F grid connected voltage source inverter to limit voltage ripple under permissible limits and hence

Impedance Modeling and Stability Analysis of Three-Phase Grid

Feb 25, 2025 · This study investigates the application of Si IGBT/SiC MOSFET hybrid modules in three-phase grid-connected inverters, focusing on the relationship between the switching

Hybrid control for capacitor-assisted Z-source inverter in grid

Feb 1, 2025 · Grid-connected inverters play an important role in linking these scattered generation sources to the electricity distribution grid. They are required to facilitate and maximize the

The role of capacitors in parallel with the power grid

series capacitor (GCSC) plays an important role to enhance grid system transfer power, stability, power quality and loss reduction. GCSC devices are implemented using fixed or The

Virtual inertia extraction from a DC bus capacitor in a three−phase DC

Dec 1, 2024 · 1. Introduction Advanced features that are offered by sophisticated and effective inverters such as autonomous and grid − connected operations, synchronous transition

Sizing of dc-link capacitor for a single phase grid

Jun 10, 2020 · The easiest way to limit the double frequency ripple voltage is to connect a capacitor in parallel to the PV module and the inverter which buffers the double line frequency

Two-stage PV grid-connected control strategy based on

Nov 30, 2023 · However, the deterioration of dynamic performance in PLL can lead to instability in VQ-VSC control within a weak grid. To improve the stability of VQ-VSC grid connection, the

Sizing of dc-link capacitor for a grid connected solar

Abstract of a dc-link capacitor for a grid connected photovoltaic inverter. Methods: Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic

DC-Link Capacitor Diagnosis in a Single-Phase Grid

In this study, a two-stage diagnostic approach that is aimed at determining the health status of the DC-link capacitor in a single-phase grid-connected PV system was proposed.

DC-Link Capacitor Voltage Balancing Technique for

Aug 11, 2025 · Abstract—The Five-Level Active-Neutral-Point-Clamped (5L-ANPC) inverters are receiving more attentions as one of preferred solutions for medium and high power

High-efficiency Diagnosis of DC-link Capacitors in Grid-connected

Oct 20, 2022 · The grid-connected photovoltaic (PV) power generation system which has multiple parallel DC modules is popularly applied in industry. In each DC-DC converter, t

Analysis of Output DC Current Injection in Grid

Apr 27, 2024 · an accidently be produced by grid connected inverters which can create large DC current injections. If output transformers are not used, these inverters must prevent excessive

A novel adaptive switching method to reduce DC-Link capacitor

Oct 1, 2018 · In order to minimize the DC-link capacitor, a series voltage compensator has been added between the DC-link capacitor and DC-AC converter in the application of grid

6 FAQs about [The role of DC capacitors in grid-connected inverters]

How does a DC capacitor work in a solar inverter?

Therefore, controlling the dc capacitor charge arbitrates solar energy extraction and simultaneous injection into the grid. At the initial start of the inverter, the dc capacitor is charged to the open circuit voltage of the solar farm, where the incoming power is zero but exhibits the maximum natural force for grid power injection.

What is the function of a capacitor in an inverter?

As the converter and inverter blocks have separate controls, this capacitor serves as the voltage reference for the inverter. Implementing photovoltaic (PV) systems as direct power sources for motors without batteries is a complex process that requires a sophisticated control mechanism.

How reliable is a DC-link capacitor in a grid connected photovoltaic system?

Methods: Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic systems and needs effort to design a reliable and optimal size capacitor as its reliability is concerned with the overall system reliability.

Does a 3KW grid connected PV system need a capacitor?

The simulations based on 3kW grid connected PV system are carried out in DIgSILENT Power Factory software. Findings: A capacitor of 410µF is needed to be connected in parallel with a 3kVA inverter having an nominal input voltage of 370V and maintaining a voltage ripple under 8.5%.

Can a microgrid control the power of an inverter?

The local load could be operated either from converter itself or grid, hence the system could be called microgrid. In this paper, the active and reactive powers would be controlled separately when the inverter is connected to the grid. While in the islanded or autonomous mode, the proposed control would support the voltage and frequency.

What if voltage and frequency control is lost in grid following inverter?

Thus, if voltage and frequency control is lost in grid following inverter, the system have to be shut down. This issue is solved by employing grid forming, which would provide controllable voltage and frequency similar to that in grid connected synchronous generator. That approach is advantageous compared to grid following inverter control.

Learn More

- Grid-connected inverter converted to DC output

- The role of DC inverter

- Photovoltaic grid-connected cabinets and inverters

- What are the technical specifications for grid-connected operation and maintenance of communication base station inverters

- Grid-connected inverters in parallel

- The role of batteries and inverters

- Multiple photovoltaic grid-connected inverters in parallel

- North Africa Super DC Capacitors

- How much does a photovoltaic grid-connected combiner box cost

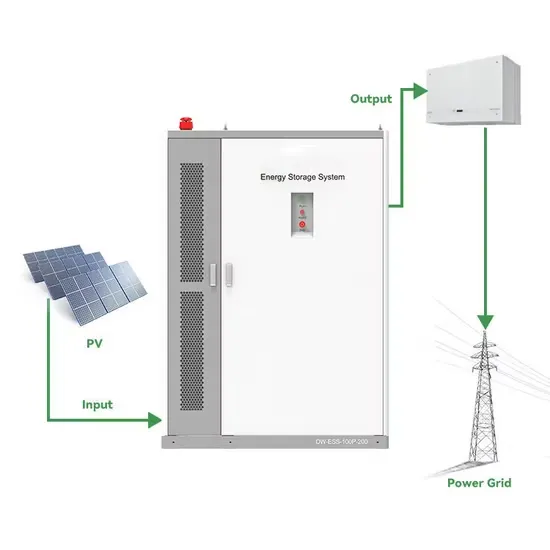

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.