Electrolytes for bromine-based flow batteries: Challenges,

Jun 1, 2024 · Herein, we first summarize the physicochemical properties and composition of electrolytes for Br-FBs. Notably, the spectroscopic characterization methods are also

A solid electrolyte with active stability

Aug 15, 2025 · An electrolyte, typically a solution based on LiPF 6 in an organic solvent, allows for Li + ion transport inside the cell, while electrons flow externally in a wire for battery operation.

The Effect of Electrolyte Composition on the

Dec 24, 2023 · The iron‐chromium redox flow battery (ICRFB) is considered the first true RFB and utilizes low‐cost, abundant iron and chromium chlorides as

Aqueous iron-based redox flow batteries for large-scale

May 31, 2025 · To address these issues, various strategies have been developed, such as modifications to electrolytes, electrodes and separators, as well as flow stack optimization.

Adjustment of Electrolyte Composition for All-Vanadium

Oct 16, 2023 · Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with total vanadium, total sulfate, and

A low-cost sulfate-based all iron redox flow battery

Nov 30, 2021 · Abstract Redox flow batteries (RFBs) are promising choices for stationary electric energy storage. Nevertheless, commercialization is impeded by high-cost electrolyte and

Adjustment of Electrolyte Composition for All‐Vanadium

Oct 16, 2023 · Flow batteries (FBs) are currently applied for conversion and storage of renewable energy in large grids to reduce the consumption of fossil fuels for energy con- version and

Electrochemical analysis of electrolyte temperature and composition

Electrochemical analysis of electrolyte temperature and composition for all-iron redox flow battery International Journal of Green Energy 10.1080/15435075.2021.1990067 2021

Analyses and optimization of electrolyte concentration on

Aug 1, 2020 · In order to improve the electrochemical performance of iron-chromium flow battery, a series of electrolytes with x M FeCl2 + x M CrCl3 + 3.0 M HCl (x

An optimistic approach on flow rate and supporting electrolyte

Aug 20, 2021 · Herein for the first time, we have successfully demonstrated the influence of flow rate on the polarization effect caused by the sluggish kinetics of Br− /Br 2 redox couple in zinc

Analysis of Li-ion battery electrolytes with ion

Aug 12, 2025 · The Li ions from the liquid electrolyte balance this flow [2]. Consequently, the lithium battery electrolyte composition is crucial for the

Electrolytes for bromine-based flow batteries: Challenges,

Jun 1, 2024 · Among them, electrolyte optimization is one of the most promising strategies because of its great economy and feasibility, which includes electrolyte composition

Restoring capacity and efficiency of vanadium redox flow battery

Jun 15, 2023 · Vanadium redox flow battery (VRFB) is a well-established redox flow technology with great potential for renewable grid energy storage systems [[1], [2], [3]]. This device stores

Preparation of vanadium flow battery electrolytes: in-depth

Jul 10, 2025 · The preparation technology for vanadium flow battery (VRFB) electrolytes directly impacts their energy storage performance and economic viability. This review analyzes

The Effect of Electrolyte Composition on the

Dec 24, 2023 · Most importantly, iron-chromium flow battery with the optimized electrolyte presents excellent battery efficiency (coulombic efficiency: 97.4%;

High-performance zinc bromine flow battery via improved

Jul 1, 2017 · The zinc bromine flow battery (ZBFB) is regarded as one of the most promising candidates for large-scale energy storage attributed to its high energy density and low cost.

Restoring capacity and efficiency of vanadium redox flow battery

Jun 15, 2023 · Vanadium redox flow battery (VRFB) is a well-established redox flow technology with great potential for renewable grid energy storage systems [ [1], [2], [3]]. This device stores

SECTION 5: FLOW BATTERIES

Jun 14, 2022 · Volume of electrolyte in external tanks determines energy storage capacity Flow batteries can be tailored for an particular application Very fast response times- < 1 msec Time

Flow batteries, the forgotten energy storage device

Jan 21, 2025 · Redox flow batteries have a reputation of being second best. Less energy intensive and slower to charge and discharge than their lithium-ion

Engineered Reactor Components for Durable Iron Flow Batteries

Jan 30, 2024 · All-iron redox flow battery (IRFB) is a promising candidate for grid-scale energy storage because of its affordability and environmental safety. This technology employs iron

Electrolyte Compositions in a Vanadium Redox Flow Battery

Sep 9, 2019 · Abstract This work explores a novel reference cell for simultaneously assessing the compositions of the positive and negative electrolytes in a vanadium redox flow battery. The

A review on the electrolyte imbalance in vanadium redox flow batteries

Sep 20, 2019 · In this review, the electrolyte imbalance in vanadium redox flow batteries is considered to reduce deterioration in battery performance. The electrolyte imbalance can be

Aqueous iron-based redox flow batteries for large-scale

May 31, 2025 · Despite extensive research efforts in electrolyte optimization, commercial all-iron flow batteries, according to the ESS Energy Center datasheet, still rely on a relatively simple

High energy density electrolytes for H2/Br2 redox flow batteries

Jan 25, 2021 · High energy density electrolytes for H2/Br2 redox flow batteries, their polybromide composition and influence on battery cycling limits†

6 FAQs about [Flow battery electrolyte composition]

What is a Commercial electrolyte for vanadium flow batteries?

Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with total vanadium, total sulfate, and phosphate concentrations in the range from 1.4 to 1.7 m, 3.8 to 4.7 m, and 0.05 to 0.1 m, respectively, are prepared.

Why is electrolyte engineering important for all-iron flow batteries?

For all-iron flow batteries, electrolyte engineering is particularly important to mitigate HER, which competes with iron redox reactions. Additionally, optimizing carbon-based electrodes through surface modifications or catalyst coatings can enhance charge transfer efficiency.

What is the difference between Fe-organic and Fe-Ce flow batteries?

Meanwhile, Fe–organic flow batteries (Fe 2+ /Fe 3+ || organic redox species) leverage redox-active organic molecules to enhance tunability and cycle life, while Fe–Ce flow batteries (Fe 2+ /Fe 3+ || Ce 3+ /Ce 4+) provide higher voltages (∼1.34 V) but require careful electrolyte management.

Are aqueous all-iron flow batteries a good choice?

Electrochemical analysis of electrolyte. At present, aqueous all-iron flow batteries have become one of the most potentials flow batteries system due to their low cost and environmental-friendly operation.

Are all-iron flow batteries suitable for high-temperature conditions?

Based on the analyses, it is proved that the electrolyte of an all-iron flow battery is suitable for high-temperature conditions. By comparing the electrochemical performance of anolyte and anolyte with citrate, the citrate is proved to be an effective additive in solving the problem of anolyte reversibility.

How long do all-iron flow batteries last?

Despite extensive research efforts in electrolyte optimization, commercial all-iron flow batteries, according to the ESS Energy Center datasheet, still rely on a relatively simple FeCl 2 -based electrolyte composition, with an expected lifespan of 25 years.

Learn More

- Composition of Huawei s new liquid flow battery

- Flow battery electrolyte corrosiveness

- Algeria large capacity all-vanadium flow battery electrolyte pump

- What is the electrolyte of a flow battery

- Composition of liquid flow energy storage battery

- Which type of flow battery is better

- Iron-based liquid flow battery energy storage system

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Africa s new all-vanadium liquid flow battery

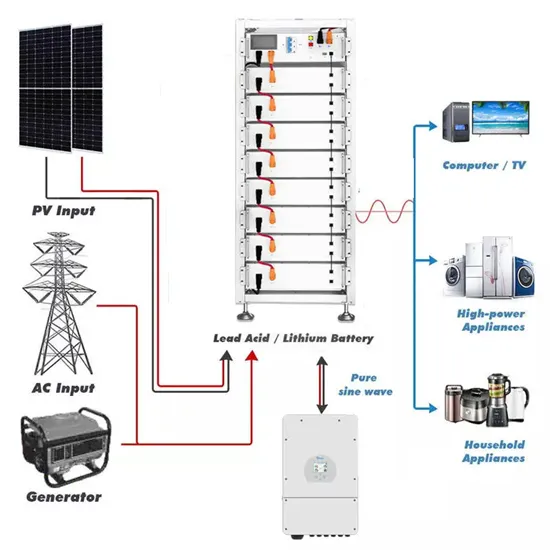

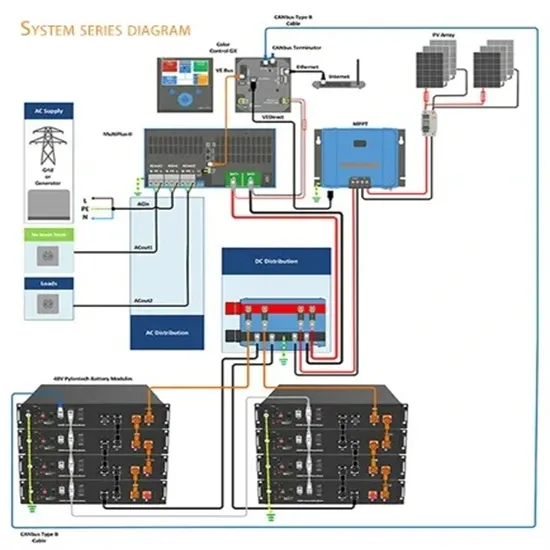

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.