Review on modeling and control of megawatt liquid flow energy storage

Jun 1, 2023 · In this paper, the overall structure of the megawatt-level flow battery energy storage system is introduced, and the topology structure of the bidirectional DC converter and the

Electrolyte engineering for efficient and stable vanadium redox flow

May 1, 2024 · Abstract The vanadium redox flow battery (VRFB), regarded as one of the most promising large-scale energy storage systems, exhibits substantial potential in the domains of

Origin-backed energy storage start-up unveils

Mar 30, 2025 · NSW-based company unveils its proprietary microemulsion flow battery technology for the first time, promising a breakthrough in long duration

New Flow Battery Chemistries for Long Duration Energy Storage

Sep 27, 2024 · Abstract: Flow batteries, with their low environmental impact, inherent scalability and extended cycle life, are a key technology toward long duration energy storage, but their

Technology: Flow Battery

Nov 4, 2024 · A flow battery is an electrochemical battery, which uses liquid electrolytes stored in two tanks as its active energy storage component. For charging and discharging, these are

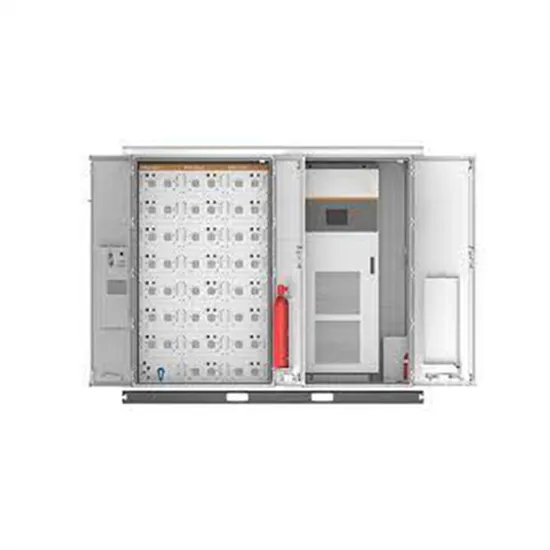

Composition of energy storage container

o Flow batteries: Utilize liquid electrolytes, ideal for large-scale storage with long discharge times. o Flywheels: Store energy in the form of kinetic energy, suitable for short-term storage and

Flow batteries, the forgotten energy storage device

Jan 21, 2025 · Redox flow batteries have a reputation of being second best. Less energy intensive and slower to charge and discharge than their lithium-ion

What does liquid flow energy storage include

Theseelectrochemical storage systems vary in composition and can include lead-acid, redox flow, molten salt and lithium-ion batteries. Lithium-ion batteries currently dominate the market for

Maximizing Flow Battery Efficiency: The Future

May 26, 2024 · What is a Flow Battery? Before diving into the specifics of flow battery efficiency, it''s important to understand what flow batteries are and how

Liquid flow battery energy storage model principle

Flow batteries are a unique class of electrochemical energy storage devices that use electrolytes to store energy and batteries to generate power [7].This modular design allows for

6 FAQs about [Composition of liquid flow energy storage battery]

What is liquid flow battery energy storage system?

The establishment of liquid flow battery energy storage system is mainly to meet the needs of large power grid and provide a theoretical basis for the distribution network of large-scale liquid flow battery energy storage system.

Does a liquid flow battery energy storage system consider transient characteristics?

In the literature , a higher-order mathematical model of the liquid flow battery energy storage system was established, which did not consider the transient characteristics of the liquid flow battery, but only studied the static and dynamic characteristics of the battery.

What is a lithium ion battery with a flow system?

Lithium-ion batteries with flow systems. Commercial LIBs consist of cylindrical, prismatic and pouch configurations, in which energy is stored within a limited space 3. Accordingly, to effectively increase energy-storage capacity, conventional LIBs have been combined with flow batteries.

Which materials can be used in flow batteries?

Large quantities of active materials are needed to store the generated energy in grid-scale EES systems. Vanadium and lithium metals are not abundant resources, and therefore sodium and zinc are being considered as alternative materials for use in flow batteries.

How a liquid flow energy storage system works?

The energy of the liquid flow energy storage system is stored in the electrolyte tank, and chemical energy is converted into electric energy in the reactor in the form of ion-exchange membrane, which has the characteristics of convenient placement and easy reuse , , , .

What are aqueous flow batteries?

Aqueous flow batteries can provide a rapid response time and good flowability of the catholytes and anolytes with minimum pump loss, thus facilitating the storage of the generated energy.

Learn More

- Iranian all-vanadium liquid flow energy storage battery

- South Tarawa All-vanadium Liquid Flow Battery Energy Storage

- Liquid flow vanadium energy storage battery

- 50mw all-vanadium liquid flow battery energy storage power station

- Nanya Luojia Power Grid All-vanadium Liquid Flow Battery Energy Storage

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- The right is the all-vanadium liquid flow energy storage battery

- What are the liquid cooling components of liquid-cooled energy storage battery pack

- Photovoltaic all-vanadium liquid flow energy storage

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.