SECTION 5: FLOW BATTERIES

Jun 14, 2022 · K. Webb ESE 471 3 Flow Batteries Flow batteries are electrochemical cells, in which the reacting substances are stored in electrolyte solutions external to the battery cell

Vanadium Flow Battery: How It Works and Its Role in Energy

Mar 3, 2025 · A vanadium flow battery works by circulating two liquid electrolytes, the anolyte and catholyte, containing vanadium ions. During the charging process, an ion

Bringing Flow to the Battery World

Mar 20, 2024 · What is a flow battery? A redox flow battery (RFB) consists of three main spatially separate components: a cell stack, a positive electrolyte (shortened: posolyte) reservoir and a

DOE ESHB Chapter 6 Redox Flow Batteries

Feb 18, 2021 · Abstract Redox flow batteries (RFBs) offer a readily scalable format for grid scale energy storage. This unique class of batteries is composed of energy-storing electrolytes,

Flow batteries, the forgotten energy storage device

Jan 21, 2025 · Redox flow batteries have a reputation of being second best. Less energy intensive and slower to charge and discharge than their lithium-ion

Electrolyte engineering for efficient and stable vanadium redox flow

May 1, 2024 · This paper provides a review of electrolyte properties, supporting electrolytes, electrolyte additives, synthesis methods, and their impact on battery performance. Moreover,

Next-generation Flow Battery Design Sets

Jul 10, 2023 · Flow batteries provide long-lasting, rechargeable energy storage, particularly for grid reliability. Unlike solid-state batteries, flow batteries store

What is Electrolyte in a Battery?

Jan 14, 2024 · In conclusion, the electrolyte is an essential component of a battery. It enables the transfer of ions and the flow of electrical current, ultimately allowing the battery to function.

Flow Battery Basics: How Does A Flow Battery Work In

Mar 2, 2025 · Flow batteries operate by pumping liquid electrolyte solutions through two separate chambers. One chamber contains a positive electrolyte, while the other has a negative one.

Flow Battery Basics: Understanding The Technology

Dec 31, 2023 · How Does a Flow Battery Work? Flow batteries operate on the principle of converting chemical energy into electrical energy through the redox (reduction-oxidation)

What Is an Electrolyte in a Battery? Types and Functions

What is an Electrolyte? An electrolyte is a chemical substance that contains free ions, allowing it to conduct electricity. In the context of batteries, the electrolyte is the medium that facilitates

Why Flow Batteries Are the Hottest Tech For

Oct 11, 2022 · A flow battery is a rechargeable battery that features electrolyte fluid flowing through the central unit from two exterior tanks. They can store

Vanadium flow batteries at variable flow rates

Jan 1, 2022 · Vanadium flow batteries employ all-vanadium electrolytes that are stored in external tanks feeding stack cells through dedicated pumps. These batteries can possess near limitless

Go with the flow: What are flow batteries, and how do they

Jun 26, 2024 · ESS says its iron flow systems have a 25-year service life, whereas most Li-ion batteries last about 7-to-10 years. And because flow batteries store their energy in a non

What Are Flow Batteries? A Beginner''s Overview

Jan 14, 2025 · Electrolytes: The two most important elements of a flow battery are the positive and negative electrolytes, typically stored in separate external tanks. These electrolytes are usually

6 FAQs about [What is the electrolyte of a flow battery ]

What are the elements of a flow battery?

Electrolytes: The two most important elements of a flow battery are the positive and negative electrolytes, typically stored in separate external tanks. These electrolytes are usually in liquid form and contain ions that facilitate the battery’s energy conversion process.

How do flow batteries work?

Charging and discharging are realized by means of a reversible electrochemical reaction between two liquid electrolyte reservoirs. Flow batteries are often called redox flow batteries, based on the redox (reduction–oxidation) reaction between the two electrolytes in the system. Fig. 9. Flow battery system .

How does a flow battery differ from a conventional battery?

In contrast with conventional batteries, flow batteries store energy in the electrolyte solutions. Therefore, the power and energy ratings are independent, the storage capacity being determined by the quantity of electrolyte used and the power rating determined by the active area of the cell stack.

Are flow batteries scalable?

Scalability: One of the standout features of flow batteries is their inherent scalability. The energy storage capacity of a flow battery can be easily increased by adding larger tanks to store more electrolyte.

Where is electrolyte stored in a battery?

In a battery without bulk flow of the electrolyte, the electro-active material is stored internally in the electrodes. However, for flow batteries, the energy component is dissolved in the electrolyte itself. The electrolyte is stored in external tanks, usually one corresponding to the negative electrode and one to the positive electrode.

What are flow batteries used for?

Renewable Energy Storage: One of the most promising uses of flow batteries is in the storage of energy from renewable sources such as solar and wind. Since these energy sources are intermittent, flow batteries can store excess energy during times of peak generation and discharge it when demand is high, providing a stable energy supply.

Learn More

- Freetown All-Vanadium Redox Flow Battery Electrolyte

- What is a single flow battery

- What is the prospect of vanadium flow battery

- What is the actual life of a 60v lithium iron phosphate battery pack

- What kind of protection frame should be used for battery cabinet

- What are the site energy battery cabinet equipment

- What are the liquid cooling components of liquid-cooled energy storage battery pack

- What is the largest size of cylindrical lithium battery in Afghanistan

- What are the three types of grounding for battery energy storage systems in communication base stations

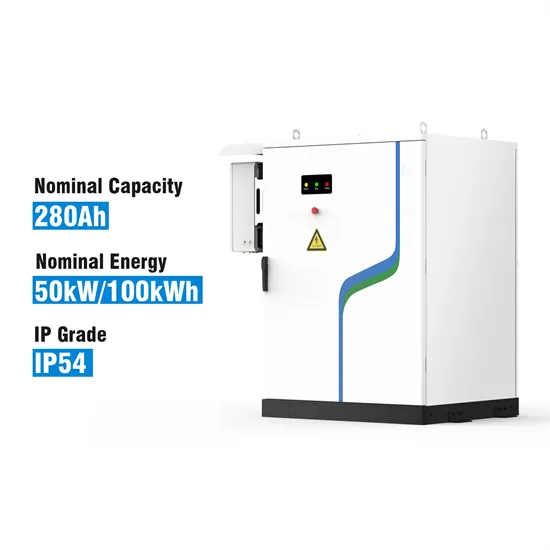

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.