What is Three Phase Inverter and How Does It Work

Aug 1, 2025 · In the world of modern energy systems, the three phase inverter plays a vital role in converting energy into a usable form. Whether in solar power setups, electric vehicles, or

Induction Machine Frequency Control: Three-Phase Bridge Inverter

Sep 11, 2009 · Abstract: Some working modalities of a three-phase bridge inverter, where the first-harmonic amplitude of the generated voltage varies by means of the output voltage

ABB Inverter Duty Motors — ABB Group

Feb 3, 2023 · Today that number has quadrupled, demonstrating that industry is aware of the potential of motor/drive pairings. ABB''s Baldor-Reliance® three-phase motors are "inverter

Global Standard VFD 380V 450V Industrial Automation Drive

Type VFD, Universal AC Drive, AC-DC-AC Variable-Frequency Drive, frequency converter, AC Drive Application motor, Pumps, AC Motor, Industrial Automation, motor speed control,

Industrial Inverters 3Ph-3Ph – Enventa Power

The Enventa 3-Phase to 3-Phase Industrial Inverter is equipped with a user-friendly LCD interface for real-time monitoring of voltage, frequency, system load, and battery status. It supports RS

Industrial frequency inverter, Industry frequency converter

The convenient ST600 series frequency inverter is a three-phase 400V frequency inverter that can be ordered in power classes from 1.5kW to 500kW. The drives support

3.7 kW Frequency Inverter, 3 Phase 220V, 380V, 480V

Favorable price 3.7 kW vfd inverter, 3 phase variable frequency drive 220V, 380V, 480V. Input frequency 50Hz/ 60Hz, output frequency 0~1000Hz, current vector control, and V/F control

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · Three-phase inverter reference design for 200–480 VAC drives with opto-emulated input gate drivers Description This reference design realizes a reinforced isolated three-phase

6 FAQs about [Riga three-phase industrial frequency inverter]

What are the control methods of a 3 phase inverter?

The control methods of the 3 phase inverter include V/F control and sensorless vector control. The frequency drive inverter has a variety of protection functions, such as overcurrent protection, overvoltage protection, grounding protection, and overheating protection.

How does a 3 phase inverter work?

Input power processing: The three-phase inverter first receives the three-phase AC power as input. Then, the input AC power is converted to DC power (DC) through the internal rectifier. The rectifier is usually implemented using a diode bridge to limit the AC sine wave to a single-direction DC waveform.

What is VFD 3 phase inverter?

Equipped with a digital screen, the vfd inverter 3 phase works at (–10℃, 40℃). It usually applies to machinery and equipment, the chemical industry, the oil and gas industry, home appliances and motors, etc. The control methods of the 3 phase inverter include V/F control and sensorless vector control.

What is a 3.7kw 3 phase variable frequency drive?

The multiple-function keyboard of the 3.7kw 3 phase variable frequency drive controls the operation of the 3.7kw variable frequency drive inverter, such as start, stop, and acceleration.

What is RS485 frequency drive inverter?

Input frequency 50Hz/ 60Hz, output frequency 0~1000Hz, current vector control, and V/F control mode for 3 phase motor speed control. With RS485 communication mode, the frequency drive inverter has an IP 20 enclosure rating, durable and rugged. 3.7 kW (5 hp) 3 phase variable frequency drive, RS485 communication mode and IP20 enclosure rating.

What is a 3.7 kW variable frequency drive inverter?

The 3.7 kw variable frequency drive inverter's rugged casing plays multiple roles in its design. It is not only about protecting the circuits and electronic components inside the device but also about the safety, stability, and reliability of the device.

Learn More

- Three-phase industrial frequency inverter wholesale price

- Assembly of high power industrial frequency inverter

- New generation of intelligent industrial frequency high power inverter

- Ghana industrial frequency off-grid inverter price

- Industrial frequency sine wave inverter multifunctional LCD

- Industrial frequency inverter adjusts the working voltage

- Abuja Industrial Frequency Pure Sine Wave Inverter

- Industrial frequency high frequency low frequency inverter

- Industrial frequency inverter 192v to 220v

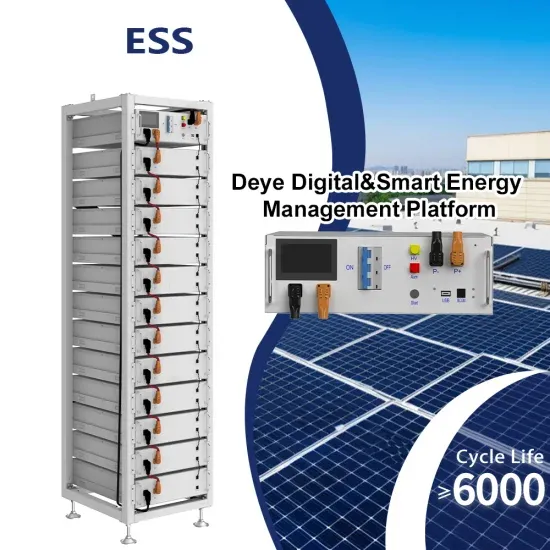

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.