Post-earthquake functional state assessment of communication base

Dec 1, 2024 · The method considers the dependence between the equipment and its hosting building structure, and the impact of power outages. This model produces seismic functional

Environmentally-Friendly, Disaster-Resistant Green Base

Nov 29, 2013 · In this article, we give an overview of the green base station concept and describe our test equipment and basic operational results. 1. Introduction. teries instead of lead storage

Power Supply Testing | Keysight

Mar 1, 2024 · Power Supply Testing As regulated-power supply technology evolves, testing methods for design verification and product function require more sophisticated electronic

Base Station Transmits: Installation

Nov 11, 2021 · Traditional 4G/LTE test methods typically involve transmitting the expected power level while a network technician conducts measurements using equipment physically

DC Power Supplies for Base Station Testing | Keysight

Keysight Technologies, Inc. can help you quickly design the power supply portion of your system, leaving more time for you to concentrate on the critical issues of leading-edge base station

6.2 Base Station output power – TechSpec

6.2.1 Base Station maximum output power 6.2.1.1 Definition and applicability Output power of the Base Station is the mean power delivered to a load with resistance equal to the nominal load

Building better power supplies for 5G base stations

May 25, 2025 · Building better power supplies for 5G base stations Authored by: Alessandro Pevere, and Francesco Di Domenico, both at Infineon Technologies Infineon Technologies -

Power Supply Solutions for Wireless Base Stations Applications

The telecommunications infrastructure and equipment is becoming increasingly more sophisticated, as wireless technology evolves, so does the need for increasingly more reliable

Communications System Power Supply Designs

Apr 1, 2023 · Voice-over-Internet-Protocol (VoIP), Digital Subscriber Line (DSL), and Third-generation (3G) base stations all necessitate varying degrees of complexity in power supply

6.2 Base station output power – TechSpec

1) Connect the power measuring equipment to the base station antenna connector. 1) For a BS declared to be capable of single carrier operation only, set the BS to transmit a signal in

5990-5019en_base-sta_rev2_11-16-09 dd

Nov 9, 2024 · Overview Electronic subassemblies for base stations derive individual circuit voltages from a main DC bus voltage through a series of DC/DC regulators. Due to the

5990-5019en_base-sta_rev2_11-16-09 dd

Nov 9, 2024 · When first powered on base station equipment draws significant inrush current from the DC bus, the peak often exceeding the average up to 50-fold. Telecommunications stan

Power Supply Testing (with Electronic Loads)

Apr 14, 2023 · Switching power supplies technology evolves, testing methods for design verification and product function require more sophisticated electronic equipment. The different

Estimate health condition of power supply at base-station

Nov 20, 2017 · Switching power supply is the most important energy device at base-station site. Its reliable operation has a direct impact on safe running of mobile telecom ne

Choosing the right size power supply for your

Apr 16, 2020 · How do you power a mobile radio for use as a base station? Get a power supply. But this isn''t a cut and dry, one-size-fits-all sort of thing.

HUAWEI DBS3900 Dual-Mode Base Station Hardware

Mar 26, 2022 · DBS3900 Dual-Mode Base Station is the fourth generation base station developed by Huawei. It features a multi-mode modular design and supports three working modes: GSM

Maintenance of communication base station power supply

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

Telecom Base Station IoT Energy Monitoring Solution

Aug 14, 2025 · Multiple DC sub circuits mainly used for DC power supply of DC loads like "Base Station Equipment" in base station [DC Power Distribution]

6 FAQs about [Base station equipment power supply test]

What instruments are used in power supply testing?

The tests covered in the follow-ing section are configured with standard instrumentation: electronic loads, digital oscilloscopes, digital multime-ters, true rms voltmeters, wattmeters, and ac power sources. Electronic loads can facilitate power supply testing in several ways.

What is a green base station?

Another feature of the green base station concept is its ability to create value during ordinary times as well, by controlling the supply of power from appropriate power sources according to conditions and reducing use of com- mercial power, thus contributing to environmental protection.

What is a power supply test?

Power supplies are used in a wide variety of products and test systems. As a result, the tests performed to determine operating specifications can differ from manufacturer to manufacturer, or from end user to end user. For instance, the tests performed in an R&D environment are primarily for power supply design verifica-tion.

How do electronic loads facilitate power supply testing?

Electronic loads can facilitate power supply testing in several ways. They are typically pro-grammable, although most require external DAC program-mers. This capability enables finer control over loading values during testing, and can provide the test set operator with valu-able status information.

What is a green base station test system?

Environmentally-Friendly, Disaster-Resistant Green Base Station Test Systems tions, which are radio base stations with environmentally friendly, disaster resistant energy systems.

What is the difference between power supply testing and automation?

In contrast, power supply testing in production environments primarily focus on overall function based on the specifi-cations determined during the products design phase. Automation is often essential due to large volume testing, which requires high test throughput and test repeatabil-ity.

Learn More

- Does the base station power supply equipment have a battery

- Communication base station solar equipment communication power supply

- China Mobile 5g base station power supply equipment supplier

- Railway base station equipment and power supply

- Uninterruptible power supply equipment for Nuku alofa communication base station

- Base station power supply supporting equipment

- Base station power supply equipment mainly includes

- Base station wind power supply equipment manufacturers

- Mobile base station equipment power supply unit

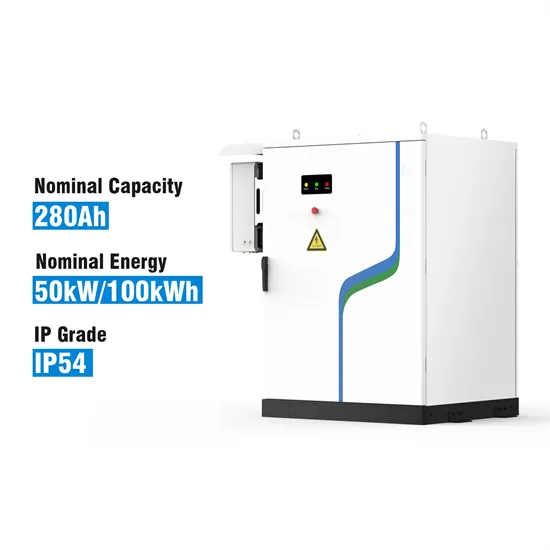

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

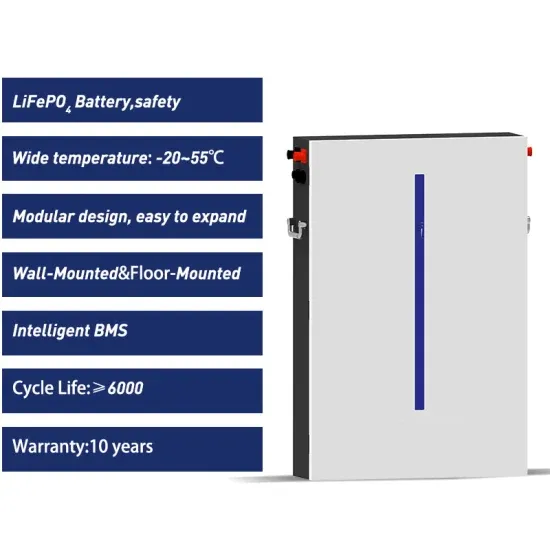

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.