Railway Traction Power Supply

Aug 7, 2025 · Hitachi Energy takes care of design, engineering, construction and commissioning of complete traction power supply systems for both long distance rail and mass transit

EN 50155: The Essential Standard for Power Supply Design

Jun 2, 2023 · EN 50155 is a European standard that covers electronic equipment used on rolling stock for railway applications, including power supplies. Though the standard was developed

A Design Overview of Traction Power Supply System for

Dec 8, 2015 · Abstract: A good high-speed railway system should provide reliable services and seamless interoperability with other railway systems. A reliable traction power supply system is

Intelligent Operation and Maintenance Platform for Power Supply

Feb 22, 2022 · Abstract In order to ensure the safe, punctual and efficient operation of Shanghai urban rail transit and ensure the stable operation of power supply system. It is necessary to

(PDF) Traction Power Supply Systems in Electrical Railways Power

Jan 23, 2022 · This report mainly focuses on the research paper "Traction Power System Simulation in Electrified Railways", this provides some basic parameters of Electric Traction

Power Distribution and Railway Management | Swartz

Feb 10, 2025 · Conclusion Power distribution is a fundamental aspect of railway management, ensuring seamless operations, safety, and efficiency. From train propulsion to station utilities,

Unit Railway Power Supply Systems

Aug 29, 2023 · Railway substations and distribution stations mainly include the following types: 110 kV/10 kV substations, 10 kV distribution stations, 10 kV/0.4 kV substations and 10 kV/0.4

Unit Railway Power Supply Systems

Aug 29, 2023 · The picture on the left shows the railway overhead power lines. They transmit the electric power from the substation and distribution stations to the electrical equipment along

Primary Power Supply for Efficient Railway Operations

Nov 18, 2024 · Reliable Primary Power Supplies in railway operations cannot be overemphasized, from providing consistent service, improving passenger safety, and supporting environmental

Primary Power Supply for Efficient Railway Operations

Nov 18, 2024 · Optimize railway efficiency with Swartz Engineering''s reliable Primary Power Supply solutions designed for seamless, uninterrupted rail operations.

Traction power supply system of China high-speed railway

Oct 1, 2023 · The Chinese railway industry will be encouraged to reach its high-quality and sustainable development goal by seizing the opportunity presented by the evolution of the high

A Pocket book on INTEGRATED POWER SUPPLY

Oct 17, 2019 · The Integrated Power Supply (IPS) provides stable and reliable power supply. This Pocket Book on Integrated Power Supply has been prepared for dissemination of knowledge

Railway Power Systems and Overhead Lines | Swartz

Aug 26, 2024 · Conclusion Railway power systems and overhead lines are integral to the operation of modern electric railways, providing the energy needed to power trains efficiently

How a Rail Grounding System Protects Infrastructure

Dec 23, 2024 · This includes the rails, power supply equipment, signaling systems, and station equipment. The goal is to ensure that any electrical faults are safely diverted through the

SECURED POWER FOR RAILWAY INFRASTRUCTURES

Jul 31, 2023 · AEG Power Solutions is the only power supply manufacturer running in-house electromagnetic tests in its own lab, to check its equipment compliance with the relevant

Railway Traction Power Supply and Electrification Solutions

Oct 13, 2022 · RECOM and PCS have an extensive portfolio of rugged EN 50155-compliant DC/DC converter products and provide turn-key solutions for rail

Railway Electrification | DC Traction Power

5 days ago · DC Traction Power Supply for Railway Wherever DC substations are found, Sécheron DC electrification equipment helps deliver power and provide

Traction power systems for electrified railways:

Jan 29, 2024 · Abstract Traction power systems (TPSs) play a vital role in the operation of electrified railways. The transformation of conventional railway TPSs to novel structures is not

Railway Energy Part 1: traction power system

Jul 7, 2022 · EN 50388 - Railway Applications – Power Supply and Rolling Stock – Technical Criteria for the Coordination Between Power Supply (Substation) and Rolling Stock to achieve

CHAPTER I POWER SUPPLY FOR TRACTION Para No

Apr 19, 2018 · 20106 Shut-Downs of Traction Supply to be Pre-Planned a) At all grid sub-stations and traction sub-stations owned by the railways, duplicate EHV feeders are available. Most of

Traction power systems for electrified railways:

Nov 14, 2023 · Traction power systems (TPSs) play a vital role in the operation of electrified railways. The transformation of conventional railway TPSs to novel

Safe building technology and power supply for railway

Safe building technology and reliable power supply systems are required for railway operations. But how is the continued functionality of these systems guaranteed, especially in the event of

Train Equipment | The Railway Technical Website

Oct 1, 2019 · Here we discuss the auxiliary services required by trains and how they are arranged on locomotives and passenger vehicles. Put simply, a train

Railway Energy Part 1: traction power system

Jul 7, 2022 · em (ECCS Energy command and control system). It forms a fully functional 2x25 kV ac traction power supply and distribution system and provides the traction power to the

The Traction Power Substation in Railway Systems

Jun 11, 2024 · The primary function of a Traction Power Substation is to provide a reliable and efficient power supply to the railway system. Electric trains rely on

6 FAQs about [Railway base station equipment and power supply]

Why do railways need traction power supply products & solutions?

Contemporary railways require smart and energy-efficient traction power supply products and solutions to ensure safe, reliable, and environmentally sustainable operations. The document includes detailed information on the manufacturers and suppliers and their products, along with contact details, to inform your purchasing decision.

What is included in a railway electrification & power supply document?

Railway electrification and power supply systems and equipment include, but are not limited to: The document includes detailed information on the manufacturers and suppliers and their products, along with contact details, to inform your purchasing decision.

Why is rail power supply important?

Having a reliable and uninterruptible power supply is key for the functioning of the rail infrastructure across the UK. Power to the railway cannot simply ‘go down’. This can be quite a challenge with such a long and narrow infrastructure (20,000 miles of track and 2500 stations!) to get supply to, but why is rail power supply so important?

Are power distribution systems on trains safe and reliable?

Power distribution systems on trains, no matter their purpose, must be safe and reliable, which means complying with a host of standards, EN 50155 prominent among them. EN 50155 is a European standard that covers electronic equipment used on rolling stock for railway applications, including power supplies.

How long does a railway power supply last?

Railway applications always involve people, and performance and reliability are key enablers of both safety and quality. Power supplies, unless otherwise declared and documented according to the standard, must have a useful life of 20 years.

What standards apply to power supply design?

Some of those standards that especially apply to power supply design include: EN 45545-1: This standard concerns fire safety and specifies materials, construction, and testing required to mitigate fire hazards in railway applications. EN 50121-3-2: This standard addresses electromagnetic emissions and immunity for railway applications.

Learn More

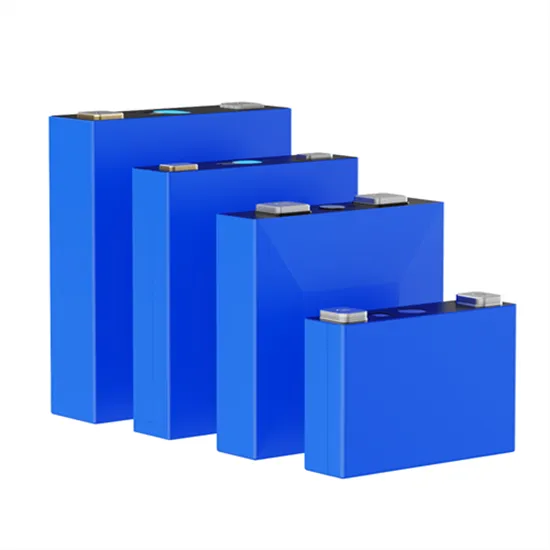

- Base station power supply supporting equipment

- Base station equipment wind power supply system

- Communication base station solar equipment communication power supply

- China Mobile 5g base station power supply equipment supplier

- Base station communication equipment power supply installation

- Solar hybrid power supply for mobile base station equipment in Paramaribo

- Skopje Base Station Power Cabinet Power Supply Equipment

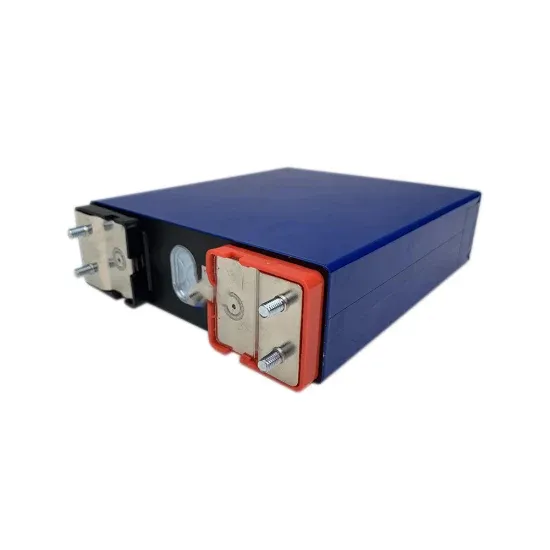

- Does the base station power supply equipment have a battery

- Mobile base station equipment power supply unit

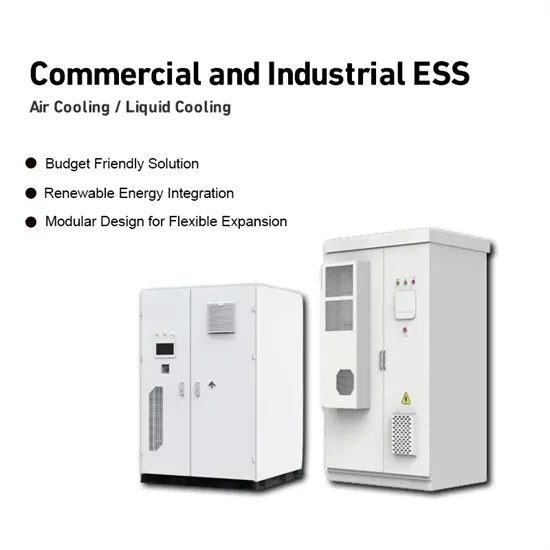

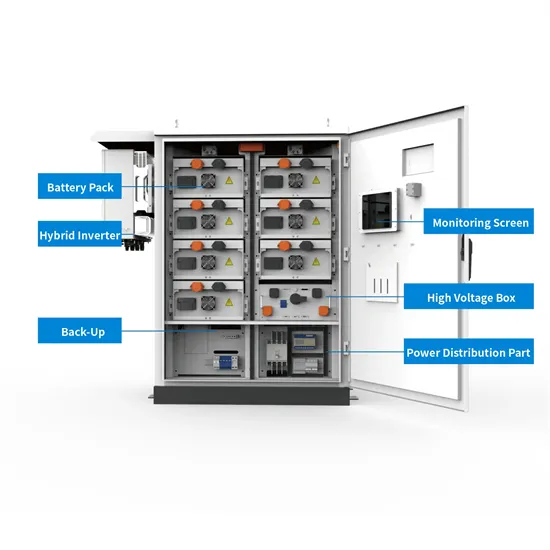

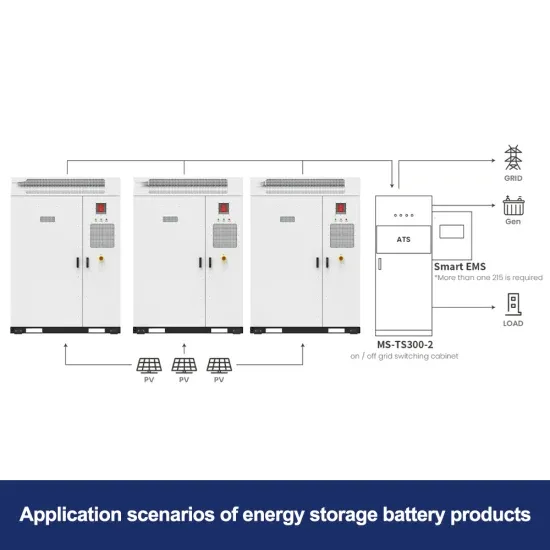

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.