Application of Anti-reverse Ammeters in Solar Energy System

Jun 26, 2024 · Application of Anti-reverse Ammeters in Solar Energy System With the rapid development of the photovoltaic industry, installed capacity is increasing. In some areas, the

Principle of Photovoltaic Anti-Reverse Current Inverter

In this review, the global status of the PV market, classification of the PV system, configurations of the grid-connected PV inverter, classification of various inverter

What Is the Reverse Flow Protection of Photovoltaic Inverters?

Reverse flow protection is a critical feature of photovoltaic (PV) inverters that ensures solar energy flows in the correct direction—away from the inverter to the home or grid, but never the other

Ankerui Energy Storage Inverter Anti-Reverse Flow Detection

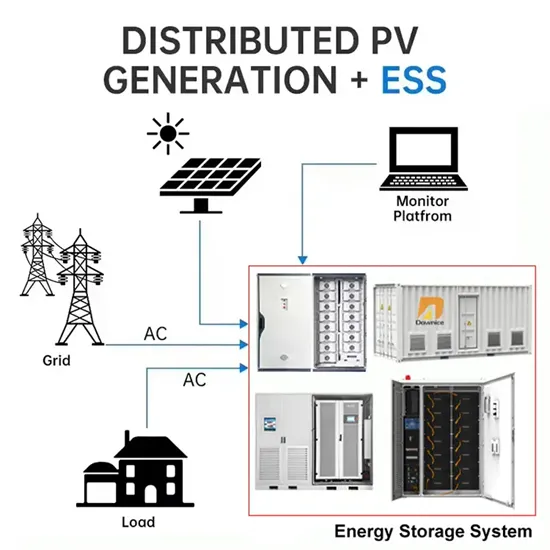

The photovoltaic energy storage system is mainly composed of power grid, photovoltaic, energy storage, power equipment, meter, and monitoring system. It uses photovoltaic power

Principle of Anti-Reverse Current of Photovoltaic Inverter

Oct 15, 2024 · For household low-power grid-connected inverters, the output current is small, generally less than 80A current models (within 50KW), you can directly use a DC anti-reverse

Principle and implementation of photovoltaic inverter anti-reverse flow

After receiving the command, the inverter responds in seconds and reduces the inverter output power, so that the current flowing from the photovoltaic power station to the grid is always kept

Photovoltaic anti-reverse current inverter installation

They''''re responsible for connecting the output of string inverters and ensuring reverse-current prevention, weather resistance, and so on. anti-reverse flow characteristics, overload safety,

Principle And Solution Of Anti Backflow For Photovoltaic Inverters

Dec 11, 2024 · Principle And Solution Of Anti Backflow For Photovoltaic Inverters Dec 11, 2024 Leave a message Generally speaking, the electricity generated by photovoltaic systems is

photovoltaic energy storage inverter anti-reverse flow

Reverse Power Flow Protection in Grid Connected PV Systems In this paper, a protection scheme against reverse power flow concerning PV integrated grid system are being discussed. This

Principle of Photovoltaic Anti-Reverse Current Inverter

Photovoltaic inverter classification There are many methods for inverter classification, for example: according to the number of phases of the inverter output AC voltage, it can be

Photovoltaic Inverter Anti-Reverse Current Principle and

In practical application, through the anti-reverse current meter + CT transformer installed on the bus on the inlet side of the house, to obtain the real-time power of the line, the size and

Photovoltaic inverter anti-reverse flow three-phase

About Photovoltaic inverter anti-reverse flow three-phase As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic inverter anti-reverse flow three-phase have

Anti-reverse charging function of photovoltaic inverter

If there are many such power generating sources to transmit electricity to the power grid,the power quality of the power grid will be seriously degraded. Therefore,this type of photovoltaic

Application and Solution of Anti-reverse Current

Jun 26, 2024 · By incorporating anti-reverse current functionality, PV system operators can ensure safe and efficient operation, eliminate reverse current

Principle And Solution Of Anti Backflow For Photovoltaic Inverters

Dec 11, 2024 · A photovoltaic system with anti backflow function can timely reduce the output power of the inverter when the power generation exceeds the load power, in order to reduce

What is anti-backflow in a solar system & How

Dec 19, 2024 · This reverse flow of energy, originating from PV modules → inverter → load → grid, is referred to as reverse current or backflow. The anti

Anti-backflow equipment in photovoltaic systems-EEWORLD

In the photovoltaic system, the direction of energy flow is photovoltaic module-inverter-load-grid, while in the power grid system, the direction of energy flow is grid-load. If it does not match

Principle and implementation of photovoltaic inverter anti-reverse flow

An anti-backflow meter + CT mutual inductor is installed on the main line on the household incoming line side to collect the real-time power, current size and direction on the busbar.

Photovoltaic micro inverter anti-reverse flow

The inverter converts DC power generated by the photovoltaic cells into AC power and provides it to the load connected to the utility line, when the photovoltaic power is greater than the load

Photovoltaic inverter anti-backflow device

How does an inverter achieve anti-backflow? Upon detecting current flow towards the grid,the inverter will reduce its output power until the countercurrent is eliminated,thereby achieving

Functions of Anti-Reverse Flow in Solar Inverters

Solar inverters play a crucial role in converting direct current (DC) generated by solar panels into alternating current (AC) that can be used to power electrical devices. One important feature of

Photovoltaic inverter anti-reverse discharge

Therefore,this type of photovoltaic power generation system must be equipped with anti-reverse flow equipment to prevent the occurrence of reverse power. How does backflow prevention

What is Backflow Prevention? Key Roles of Backflow

Feb 28, 2025 · 01 What is Reverse Power Flow? In grid-tied photovoltaic (PV) systems, excess solar power flows backward to the grid when generation exceeds local load demand. This

6 FAQs about [Photovoltaic power inverter anti-reverse flow]

What is reverse flow protection of photovoltaic inverters?

What Is the Reverse Flow Protection of Photovoltaic Inverters? Reverse flow protection is a critical feature of photovoltaic (PV) inverters that ensures solar energy flows in the correct direction—away from the inverter to the home or grid, but never the other way around.

What is a photovoltaic system with anti-backflow?

The photovoltaic system with anti-backflow is that the electricity generated by the photovoltaic is only used by the local load and cannot be sent to the grid. When the PV inverter converts the DC point generated by the PV modules into AC power, there will be DC components and harmonics, three-phase current imbalance, and output power uncertainty.

What is reverse flow protection?

Reverse flow protection is a critical feature of photovoltaic (PV) inverters that ensures solar energy flows in the correct direction—away from the inverter to the home or grid, but never the other way around. This feature is particularly important in grid-tied systems, where excess energy generated by solar panels can flow back into the grid.

Why should photovoltaic power generation system be equipped with anti-reverse flow equipment?

If there are many such power generating sources to transmit electricity to the power grid, the power quality of the power grid will be seriously degraded. Therefore, this type of photovoltaic power generation system must be equipped with anti-reverse flow equipment to prevent the occurrence of reverse power.

Why is reverse flow protection important for grid-tied solar systems?

Let’s explore why reverse flow protection is essential for grid-tied solar systems. Reverse power flow can destabilize the grid, especially in areas with high solar penetration. If too much power flows back into the grid at once, it can cause voltage fluctuations and pose a risk to other users.

How do inverters detect and manage Reverse power flow?

Inverters are designed with sophisticated monitoring systems that detect the direction of power flow and manage it accordingly. These systems prevent reverse power flow by constantly monitoring energy production and consumption. Let’s dive into the technology behind how inverters detect and manage reverse power flow.

Learn More

- Power frequency inverter dedicated to photovoltaic panels

- Montevideo Off-grid Photovoltaic Power Generation Small Inverter

- Inverter conversion for photovoltaic power generation

- Bahamas Photovoltaic Power Station Inverter

- Inverter in photovoltaic power station

- Bloemfontein Photovoltaic Power Inverter

- Photovoltaic inverter for photovoltaic power station

- Household photovoltaic power generation hybrid inverter

- Dili Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Outdoor Unit

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.