Photovoltaic power station inverter: three design solutions

A photovoltaic power station consists of components, combiner boxes, inverters, box transformers, and power grids. The centralized inverter solution is that photovoltaic

Photovoltaic inverter model parameter testing method

Oct 15, 2023 · As the penetration rate of new energy increases, the interactions between new energy power stations and grid are becoming stronger. GB 38755-2019 "Code on security and

The Differences Between Distributed PV Systems and Centralized PV

(3) Different secondary equipment used in the power station: Since the distributed photovoltaic power station is connected to the grid at low voltage 380V, it is less used for primary

Consistency control of grid-connected substation voltage

Jul 16, 2025 · To address this, a consistency control method for the voltage regulation in the grid-connected substations is proposed, based on the photovoltaic-inverter power coordination.

CHINA ELECTRIC POWER RESEARCH INSTITUTE

Jan 1, 2013 · NB/T 32008-2013 Testing code for power quality of inverters used in photovoltaic power station CGC/GF035-2013 Technical specification for China efficiency of grid connected

Industrial Design of Photovoltaic Power Station: Design Review

Dec 30, 2024 · Central to this discussion are key components of photovoltaic power station design, including solar generators, inverters, monitoring systems, and supporting

Parallel operation of inverters for distributed photovoltaic power

Jun 27, 2002 · This paper proposes a control technique for operating two or more single phase inverter modules in parallel with no auxiliary interconnections. In the proposed parallel inverter

Introduction to Photovoltaic System | SpringerLink

Sep 12, 2024 · The photovoltaic (PV) power generation system is mainly composed of large-area PV panels, direct current (DC) combiner boxes, DC distribution cabinets, PV inverters,

Simulation test of 50 MW grid-connected "Photovoltaic

Jun 1, 2024 · This study builds a 50 MW "PV + energy storage" power generation system based on PVsyst software. A detailed design scheme of the system architecture and energy storage

Equivalent Model of Photovoltaic Power Station

In order to express theoretically the fault current contributions of a PV power station, more attention has been paid to establishing the equivalent models of a PV power station.

Best Guide to Photovoltaic Inverter for Solar Power Systems

Jul 7, 2025 · At the heart of every efficient solar power system lies a crucial component: the photovoltaic inverter. This intelligent device transforms the solar energy harvested by your

Substation for photovoltaic applications with

Jun 20, 2025 · Technical description This step-up substation for photovoltaic power plants is intended for high power photovoltaic plants to increase voltage

Impedance characteristics investigation and oscillation

Aug 1, 2022 · The stability analysis is verified by the simulation results using PSCAD/EMTDC. In order to obtain impedance characteristics of the photovoltaic (PV) inverter and reveal potential

What is a photovoltaic inverter?Selection, Principles & Future

Apr 28, 2025 · A photovoltaic inverter (PV Inverter), also known as a solar inverter, is a power electronic device. Its core function is to convert the direct current (DC) generated by solar

What inverters are used in photovoltaic power stations

Oct 3, 2024 · Inverter Transformers for Photovoltaic (PV) power plants: Generic guidelines 2 Abstract: With a plethora of inverter station solutions in the market, inverter manufacturers are

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · A comprehensive analysis of high-power multilevel inverter topologies within solar PV systems is presented herein. Subsequently, an exhaustive examination of the control

PHOTOVOLTAIC POWER STATION INVERTER OFFLINE

A photovoltaic power station, also known as a solar park, solar farm, or solar power plant, is a large-scale grid-connected photovoltaic power system (PV system) designed for the supply of

Selection and Installation of Inverter in PV Power Station

Apr 2, 2025 · This paper is extracted from the building photovoltaic system design guide atlas. Includes the classification of inverters, the scope of application, and a detailed demonstration

ABB inverter station PVS800-IS – 1.75 to 2

May 29, 2019 · Turnkey solution for photovoltaic (PV) power plants The ABB inverter station design capitalizes on ABB''s long experience in the development and manufacture of

Tips for choosing photovoltaic inverters – 150 POWER

Confirm what power inverters are suitable for installing in your photovoltaic power station The installation capacity of a general power station is calculated based on the land or roof usage

6 FAQs about [Photovoltaic inverter for photovoltaic power station]

What is a photovoltaic inverter (PVI) station?

It is based on the same best-in-class power conversion platform as our AMPS solutions, enabling greater scalability and flexibility. Hitachi Energy’s Photovoltaic Inverter (PVI) station provides you with advanced control and power capabilities that are designed to meet complex technical requirements and the most challenging grid codes.

What is a PV inverter?

On the other, it continually monitors the power grid and is responsible for the adherence to various safety criteria. A large number of PV inverters is available on the market – but the devices are classified on the basis of three important characteristics: power, DC-related design, and circuit topology.

What types of inverters are used in photovoltaic applications?

This article introduces the architecture and types of inverters used in photovoltaic applications. Inverters used in photovoltaic applications are historically divided into two main categories: Standalone inverters are for the applications where the PV plant is not connected to the main energy distribution network.

How a transformer is used in a PV inverter?

To step up the output voltage of the inverter to such levels, a transformer is employed at its output. This facilitates further interconnections within the PV system before supplying power to the grid. The paper sets out various parameters associated with such transformers and the key performance indicators to be considered.

Which type of Inverter should be used in a PV plant?

One-phase inverters are usually used in small plants, in large PV plants either a network consisting of several one-phase inverters or three-phase inverters have to be used on account of the unbalanced load of 4.6 kVA.

How to pair a solar inverter with a PV plant?

In order to couple a solar inverter with a PV plant, it’s important to check that a few parameters match among them. Once the photovoltaic string is designed, it’s possible to calculate the maximum open-circuit voltage (Voc,MAX) on the DC side (according to the IEC standard).

Learn More

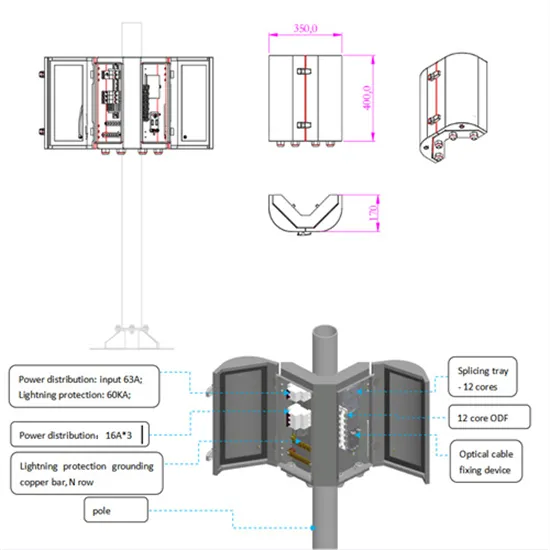

- Stockholm communication base station inverter grid-connected photovoltaic power generation system

- Rome photovoltaic power station inverter

- Eritrea communication base station inverter grid-connected photovoltaic power generation capacity

- East Asia Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Quotation

- Dili Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Outdoor Unit

- Nordic communication base station inverter photovoltaic power generation equipment

- What does wind power and photovoltaic power generation include in Antananarivo communication base station

- Castries hybrid energy 5g base station photovoltaic power generation system planning

- Grid-side power limit of photovoltaic inverter

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.