Solar Integration: Inverters and Grid Services Basics

4 days ago · Inverters are just one example of a class of devices called power electronics that regulate the flow of electrical power. Fundamentally, an

Central Inverter for Utility-Scale Solar Systems: The Key to

Mar 28, 2025 · What is a Central Inverter? PV central inverter systems are powerful devices. They are designed for large solar installations. They can process massive amounts of power from

Solar inverters and inverter solutions for power generation

Mar 13, 2020 · tensive range of solar inverters is suitable for the smallest residential photovoltaic (PV) systems right up to multi-megawatt PV power plants. For utility-scale power generation

SOLAR PV POWER GENERATION: KEY INSIGHTS AND

Mar 23, 2023 · Solar PV consists several components including solar panels, inverter, photovoltaic mounting systems and other critical accessories that make up the system. Solar

Seven-level dual-buck inverter for photovoltaic power

Oct 21, 2024 · A power processing system (PPS) with a seven-level dual-buck inverter (SLDBI) for a photovoltaic (PV) power generation system is proposed. The PPS is comprised of a

Design and performance evaluation of multilevel inverter for

Jun 18, 2024 · These pulses control the switching of the converter and inverter devices, ensuring that the power conversion process is optimized. By carefully controlling the switching actions,

Critical review on various inverter topologies for PV system

Oct 26, 2020 · These PV inverters are further classified and analysed by a number of conversion stages, presence of transformer, and type of decoupling capacitor used. This study reviews

Photovoltaic Inverter: The Key Hub for Solar Energy Conversion

Apr 28, 2025 · Gain a deep understanding of the working principles, key classifications, and crucial roles of photovoltaic inverters in solar power generation systems. This article

Seven-level dual-buck inverter for photovoltaic power generation

Aug 16, 2024 · A power processing system (PPS) with a seven-level dual-buck inverter (SLDBI) for a photovoltaic (PV) power generation system is proposed. The PPS is comprised of a

A review on single-phase boost inverter technology for low power

Feb 1, 2024 · Solar Photovoltaic (SPV) inverters have made significant advancements across multiple domains, including the booming area of research in single-stage boosting inverter

PJ12--Role-of-power-converters-for-distributed-solar-po

Aug 29, 2021 · Due to advances in switching devices, most Inverters for distributed power sources such as photovoltaic power generation now employ a Self-commutated inverter. Figure 1.

PVWatts Calculator

Mar 13, 2025 · NREL''s PVWatts ® Calculator Estimates the energy production of grid-connected photovoltaic (PV) energy systems throughout the world. It allows homeowners, small building

Grid Connected Inverter for Solar Photovoltaic Power Generation

The grid system is connected with a high performance single stage inverter system. The modified circuit does not convert the lowlevel photovoltaic array voltage into high voltage. The converter

An Introduction to Inverters for Photovoltaic (PV)

4 days ago · The inverter system can also supply and absorb reactive power independent from active power generation as illustrated in Fig. 17. The Power factor (P.F) changes from unity to

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · This paper aims to delve into the exploration of diverse structural configurations and technical hurdles encountered in high-power multilevel inverter topologies, alongside the

Modulation and control of transformerless boosting inverters

Apr 23, 2025 · This paper examines the performance of three power converter configurations for three-phase transformerless photovoltaic systems. This first configuration consists of a two

Photovoltaic Array Annual Power Generation Calculator

Formula The formula to calculate the annual power generation of a photovoltaic array is: [ P = 365 cdot H cdot A cdot eta cdot K ] where: (P) is the annual power generation (kWh)

Inverter design trade-off for photovoltaic power generation

Nov 1, 2023 · Photovoltaic (PV) power generation is a very important way of energy conversion. It can convert solar energy into electricity. As the core photovoltaic power generation device, the

(PDF) Photovoltaic power systems: A review of

Jan 1, 2012 · A two-stage boost converter topology is employed in this paper as the power conversion tool of the user-defined PV array (17 parallel strings and

6 FAQs about [Inverter conversion for photovoltaic power generation]

How do inverters work in a solar power plant?

Moreover, the inverters are interconnected in parallel with PV cells, facilitating power conversion in a singular-stage configuration. In the traditional structure of solar power plants, inverters and low-frequency transformers are utilized as an interface between PV panels and the AC grid for power transmission.

What is a high-power MV inverter?

In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency and scalability. These high-power MV systems generally function within a power range of 0.4 MW–40 MW, and in certain applications, can reach up to 100 MW.

What types of inverters are used in photovoltaic applications?

This article introduces the architecture and types of inverters used in photovoltaic applications. Inverters used in photovoltaic applications are historically divided into two main categories: Standalone inverters are for the applications where the PV plant is not connected to the main energy distribution network.

How to pair a solar inverter with a PV plant?

In order to couple a solar inverter with a PV plant, it’s important to check that a few parameters match among them. Once the photovoltaic string is designed, it’s possible to calculate the maximum open-circuit voltage (Voc,MAX) on the DC side (according to the IEC standard).

What is a single-stage power conversion system for a three-phase multilevel inverter?

In study a single-stage power conversion system for a three-phase, seven-level multilevel inverter with clamped diodes has been proposed. This novel approach eliminates the need for an intermediate dc-dc converter, leading to reduced complexity, size, and cost.

What are the applications of control systems in high-power inverters?

One of the application of control systems in high-power inverters is to increase the speed and accuracy in achieving MPPT. Control algorithms continuously examine the input of the inverter and adjust its operational parameters to extract the maximum available power . Another essential factor is computational complexity.

Learn More

- Morocco communication base station inverter grid-connected photovoltaic power generation quotation

- Algeria Photovoltaic Power Generation Equipment Inverter

- East Asia Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Quotation

- How is the photovoltaic power generation of the Tehran communication base station inverter

- Nordic communication base station inverter photovoltaic power generation equipment

- Montevideo Off-grid Photovoltaic Power Generation Small Inverter

- N Djamena photovoltaic power generation 60kw off-grid inverter

- Dili Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Outdoor Unit

- Daily power generation of photovoltaic grid-connected inverter

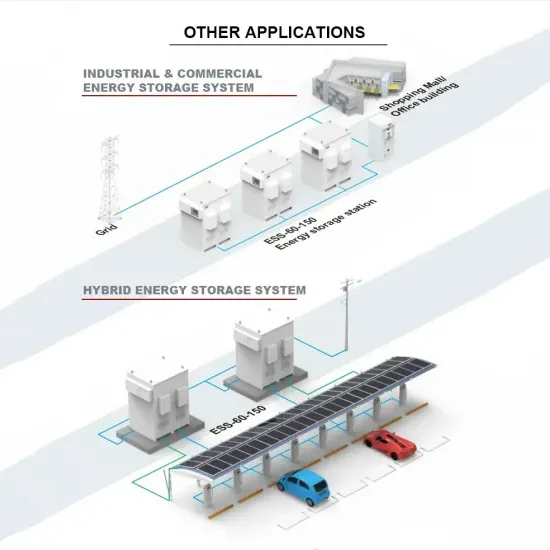

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

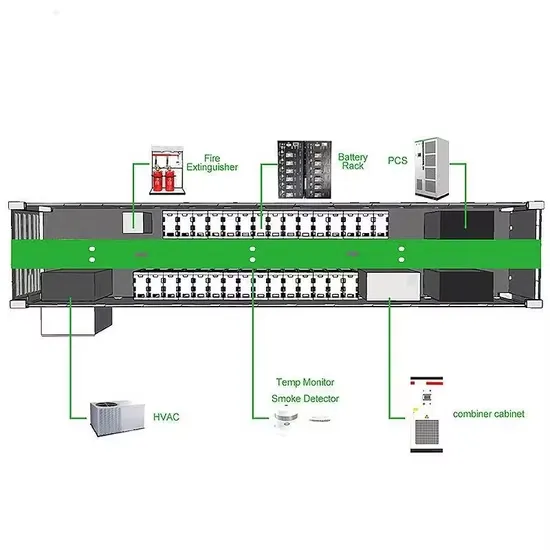

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.