Performance enhancement of multicrystalline silicon solar

May 21, 2015 · On the module level, the cell to module power transfer factor was analyzed, and it was demonstrated that the double‐layered silicon nitride antireflection coating provided a

Study about the effect of antireflection coating stacks (TiO

Nov 1, 2020 · In this paper, TiO2 –SiO 2 /SiO 2 /SiN x ARC stacks in multicrystalline silicon (Mc-Si) solar cells were designed and prepared to improve the performances of the cells under the

Multi-Crystalline Silicon Solar Cell Modules: Crack

Apr 21, 2011 · We like to present a study in which we used 40 multi-crystalline glass-foil silicon solar cell modules. The modules have been produced during the last two years. They have

Characterization of Multicrystalline Silicon Modules with

Sep 30, 2013 · We performed accelerated lifetime testing of multicrystalline silicon PV modules in 85°C/85% relative humidity (RH) and 45°C/30% RH while placing the active layer in either

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

A comparative life-cycle assessment of photovoltaic

This paper presents a comparative life-cycle assessment of photovoltaic (PV) electricity generation in Singapore by various p-type multicrystalline silicon (multi-Si) PV technologies.

Comparative Life Cycle Assessment of Photovoltaic Systems

Jul 31, 2024 · In this study, a comparative LCA on PV systems for different module technologies, i.e. monocrystalline silicon, multicrystalline silicon, cadmium telluride, copper indium selenide

Moisture induced degradation in field-aged multicrystalline silicon

Aug 15, 2023 · In hermetic PV module configurations (e.g., double glass PV modules), moisture ingress into the modules is limited. However, the escape of moisture induced degradation

Effect of materials and design on PV cracking under

Nov 1, 2022 · This section describes the geometrical development and validation of FE models for three PV module architecture designs, for a 60-cell crystalline silicon glass-backsheet module,

Why are monocrystalline wafers increasing in size?

May 21, 2024 · p-type mono-PERC bifacial cells, and half-cut and shingled technologies for modules, which are available in double-glass, multi-busbar and half-cell configurations.

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The aim of this chapter is to present and explain the basic issues relating to the construction and manufacturing of PV cells and modules from c-Si. This includes the basic

Data Sheet Multicrystalline Silicon Solar Cells-2 Bus

Nov 25, 2018 · This document provides specifications for multicrystalline silicon solar cells. The cells are 156mm x 156mm with a thickness between 240-280um. The front has an

CO2 EMISSIONS OF SILICON PHOTOVOLTAIC MODULES

Sep 27, 2022 · The CO2 emissions of the produced electricity, excluding balance of system (BoS), amount to 13-30 g CO2-eq/kWh, depending on the production location and electricity

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · The sequence of crystalline silicon solar cell production, from raw materials to modules, is shown in Figure 2. The value chain for crystalline silicon solar cells and modules is

Crystalline Silicon Solar Cells: State-of-the-Art

Jun 17, 2012 · The cost distribution of a crystalline silicon PV module is clearly dominated by material costs, especially by the costs of the silicon wafer.

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

2: Process emissions in the life cycle of multicrystalline silicon

In this report the environmental aspects of solar cell modules based on multicrystalline silicon are investigated by means of the Environmental Life Cycle Assessment method. Three technology

6 FAQs about [2 square double glass multicrystalline silicon module]

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is a crystalline silicon module?

Crystalline silicon module consists of individual PV cells connected together by soldering and encapsulated between a transparent front cover, usually glass and weatherproof backing material, usually plastic. You might find these chapters and articles relevant to this topic.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What are crystalline silicon systems?

The crystalline silicon systems are known as the first generation of PV technologies, having silicon as the primary material for producing cells. The cells are then combined to produce crystalline modules .

Learn More

- Huawei photovoltaic carport double glass module

- Double glass module bending

- Double glass module installation and fixation

- One hole double glass module

- Double glass module bipv

- Australian double glass photovoltaic module manufacturer

- South America Double Glass Module Price Per Watt

- Oslo double glass photovoltaic module price

- Mauritius Glass Photovoltaic Module Sales

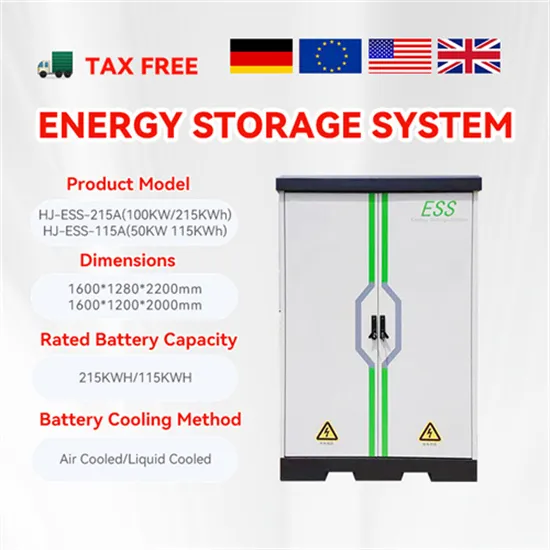

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.