INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

DAS-DH156NA-EN-620-645(2465-1134-30)

Nov 29, 2024 · Mechanical Parameters Cell Type N Type Module Size 2465×1134×30mm Glass Thickness 2.0mm + 2.0mm Module Weight 34.3Kg Output Cable 4mm2, cable length

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

JA Solar PV Bifacial Double-glass Modules Installation

Frameless double glass modules and composite frame modules need not be grounded. JA Solar modules use an anodic oxidized aluminium frame or steel frame to resist corrosion, so the

Double glass frame module one touch switch + one roller

The TW-G157.1GST double glass frame module, one touch switch + one roller shutter switch, combines elegance and functionality in one. It consists of one touch switch and one roller

JAM72D30 540-565 GB 30框72pro

Sep 23, 2022 · Introduction Assembled with 11BB bifacial PERCIUM cells and gapless ribbon connection technology, these double glass modules have the capability of converting the

What are Double Glass Solar Panels?

May 22, 2025 · The double-sided double-glass N-type module adopts a full-glass packaging structure of "glass + film (such as POE or EPE) + battery cell + film + glass", eliminating the

Growing Panes: Investigating the PV Technology Trends

Jan 20, 2025 · Additional research is needed to identify the field conditions leading to glass breakage and if there is one or multiple limiting flaws in new module designs causing glass

Installation_Manual_of_Bifacial_Module

May 11, 2020 · The word "module" or "PV module" used in this manual refers to one or more double glass solar modules. This manual is only valid for the bifacial double glass module

JA Solar PV Bifacial Double-glass Modules

Feb 1, 2021 · JA Solar modules can be mounted in landscape or portrait orientation. For the bifacial modules, in order to maintain the energy yield of module rear side, the distance

JA Solar PV Bifacial Double-glass Modules Installation

Jun 4, 2025 · Frameless double glass modules and composite frame modules need not be grounded. JA Solar modules use an anodic oxidized aluminium frame or steel frame to resist

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Aug 6, 2025 · If solar modules are installed with trackers, it is recommended to use 2.5mm thickness and 60mm height and above purlin installation with 790mm, 1200mm, 1400mm

JA SOLAR PV MODULES INSTALLATION MANUAL

Jan 29, 2019 · The modules clamps must not contact the glass directly or deform and damage the glass in any cases, clamp need embedded with the rubber washer, which plays a buffer

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with

The Difference Between Double-glass and Single

Aug 17, 2023 · The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Mar 31, 2025 · If solar modules are installed with trackers, it is recommended to use 2.5mm thickness and 60mm height and above purlin installation with 790mm, 1200mm, 1400mm

JA Solar PV Bifacial Double-glass Modules Installation

Jan 21, 2025 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Apr 14, 2025 · If solar modules are installed with trackers, it is recommended to use 2.5mm thickness and 60mm height and above purlin installation with 790mm, 1200mm, 1400mm

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

JA Solar PV Bifacial Double-glass Modules Installation

Nov 23, 2022 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar Modules.

AIKO PV Module Installation Manual

Feb 5, 2025 · Important safety instructions This Installation Manual provides information regarding the installation and safe use of PV power modules (hereinafter referred to as

6 FAQs about [One hole double glass module]

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

Are double-glass modules better than single-sided glass panels?

However, advancements in glass technology have mitigated this issue to some extent. Weight: Double-glass modules are generally heavier than single-sided glass panels due to the additional glass layer. Applications: Double-glass modules are well-suited for environments with harsh weather conditions, high humidity, or corrosive elements.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

How do double glass solar panels work?

Construction: Double-glass modules consist of two layers of glass sandwiching the solar cells and other components. The glass layers are sealed together, encapsulating the solar cells and protecting them from environmental factors.

Are double-glass modules better than glass-on-glass?

Aesthetics: Double-glass modules can offer a sleeker appearance due to the glass-on-glass design, which some people find more aesthetically pleasing. Cost: Double-glass modules tend to be more expensive to produce and install due to the added materials and manufacturing complexity.

Learn More

- Bandar Seri Begawan double glass photovoltaic module manufacturer

- Georgia photovoltaic double glass module manufacturer

- Oslo double glass photovoltaic module price

- Bulgarian double glass module manufacturer

- Double glass module installation and fixation

- Tanzania double glass photovoltaic module manufacturer

- EU double glass module manufacturer

- Huawei Portonovo double glass module

- 615wp monocrystalline double glass module price

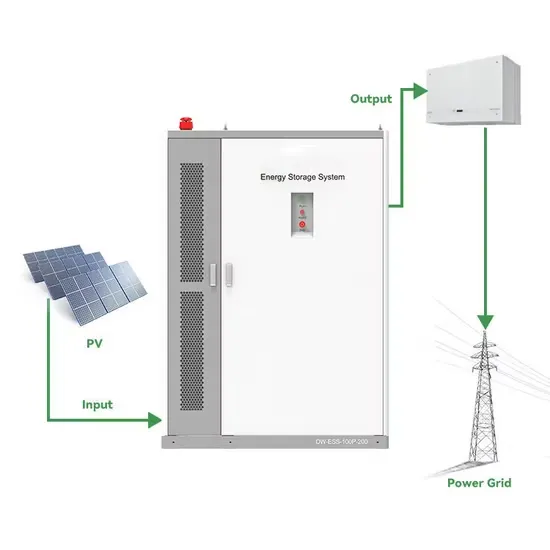

Industrial & Commercial Energy Storage Market Growth

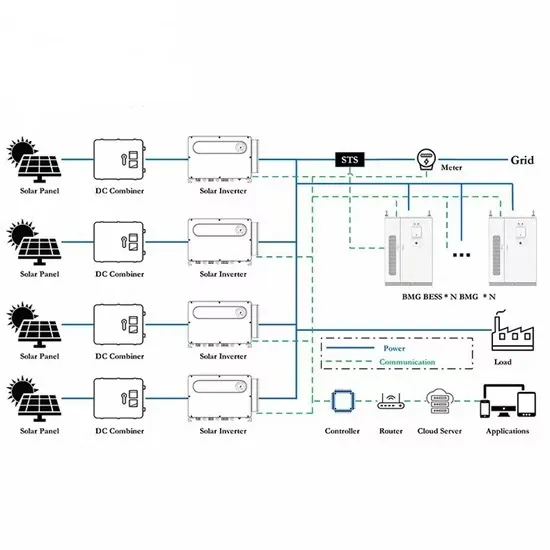

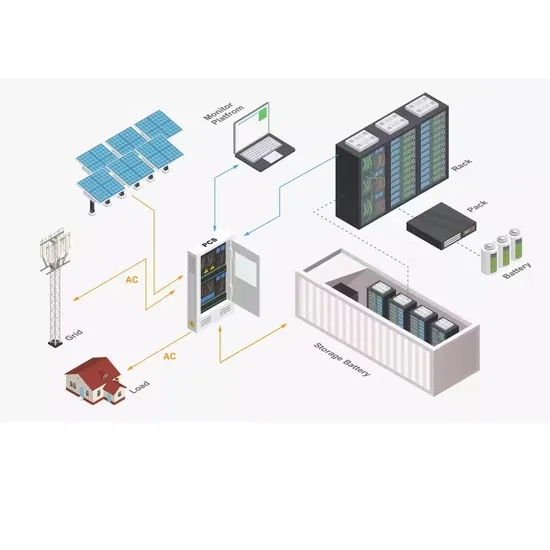

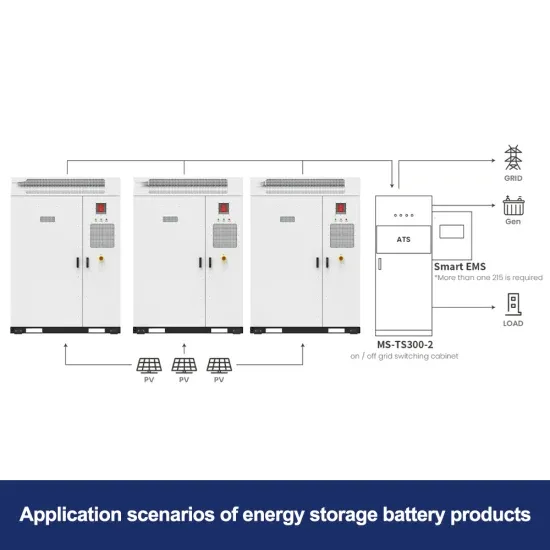

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

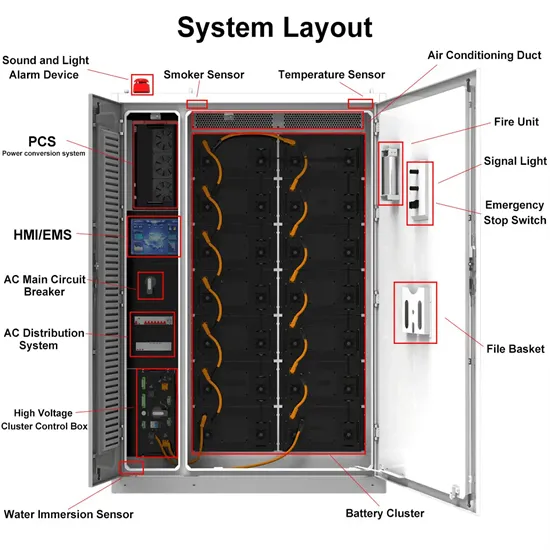

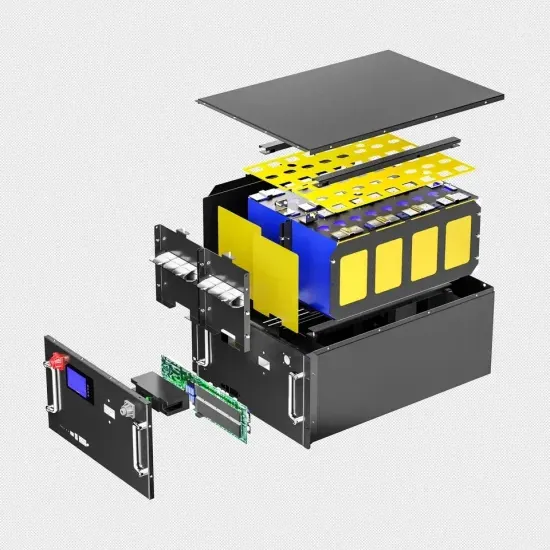

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.