T/CPIA 0028.2-2021 光伏组件用玻璃 第2部分:双玻组件

Jul 16, 2025 · T/CPIA 0028.2-2021 光伏组件用玻璃 第2部分:双玻组件背板增反射镀层玻璃 Glass for Photovoltaic Modules Part 2: Double-glass Module Backsheet Enhanced Reflection Coated

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Manufacturing Induced Bending Stresses: Glass-Glass vs. Glass

Jun 25, 2021 · The architecture of a photovoltaic module directly influences its mechanical stability, affecting cell crack propagation and contributing to the existence and d

Experimental and Theoretical Research on Bending

As to the bottom plate, it can be made of the transparent glass or opaque TPT, which makes double glass PV module or single glass PV module. Due to the requirements of lighting inside

Double Glass Module Bus-Bar Bending&Cutting Machine

Jul 30, 2025 · This equipment is designed &developed for the molding of PV Bus used in the photovoltaic double glass modules and double junction box . With advanced

Photovoltaic double-hole bending plate construction

a standard double-junction (2-J) configuration, the highest energy photons are captured by the material with the largest bandgap in the top cell, whereas the lower energy photons are

Finite Element Modeling, Thermal–Mechanical Coupling

Jul 25, 2022 · The gap-free interconnect using structural round ribbons in overlapping photovoltaic modules is an effective measure to improve module efficiency. Cells in the overlapping module

What are the differences between single-glass

Oct 22, 2020 · Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and

JA Solar PV Bifacial Double-glass Modules

Feb 1, 2021 · JA Solar modules can be mounted in landscape or portrait orientation. For the bifacial modules, in order to maintain the energy yield of module rear side, the distance

Comparative Study on Static and Dynamic Analyses of an

Aug 1, 2015 · Therefore, in this paper, a comprehensive safety evaluation including static and dynamic analyses, as well as the influence of mounting systems are investigated for an ultra

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · In double-glass or glass-glass PV modules the polymer back sheet layer is replaced by a glass layer identical to the top glass, creating a symmetrical "sandwich" structure.

PV Module User Manual-DAS-EN-2024.05

Aug 9, 2024 · Any Module installation operator shall notify the above requirements to the end users (or consumers). The "Module" or "PV Module" mentioned herein refers to one or more

双玻光伏组件介绍

Oct 31, 2017 · About double glazing panel 交大光谷双玻光伏组件,是指由两片玻璃和太阳能电池片组成复合层,电池片之间由导线串、并联汇集到引线端所形

How double-glass laminated amorphous silicon solar modules

Jun 21, 2013 · About 160 double-glass laminated amorphous silicon solar modules, which were found broken in a BIPV and a ground-mounted project sites, were shipped back to the

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules. This Manual

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Mechanical analysis of photovoltaic panels with various

Jan 1, 2020 · In BIPV, the double glass PV module with better photopermeability are more suitable and acceptable in the real structures. Therefore, the PV panels studied in the present

Mechanical analysis of photovoltaic panels with various

Mar 24, 2020 · The single glass PV module uses opaque TPT and double glass PV module adopts the transparent glass. In BIPV, the double glass PV module with better photo

6 FAQs about [Double glass module bending]

What is a double glass PV module?

Therefore, the PV panels studied in the present paper focusing on BIPV are double glass PV module which consists of two glasses and an interlayer in where the cells are sealed by ethylene vinyl acetate (EVA) or polyvinyl butyral (PVB).

Is double glass PV panel bending?

In present paper, the bending behavior of double glass PV panel is studied carefully by both experimental and theoretical research. Different from many previous researches, a special boundary condition which is two opposite edges free and the other two edges simply-supported (annotated as SSFF) is considered.

Are double glass PV panels suitable for BIPV?

In BIPV, the double glass PV module with better photopermeability are more suitable and acceptable in the real structures. Therefore, the PV panels studied in the present paper are double glass PV panel which consists of two glasses and an interlayer in where the cells are sealed by ethylene vinyl acetate (EVA) or polyvinyl butyral (PVB).

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double-glazing PV module?

Introduction The PV module studied in this paper is an ultra-thin double-glazing module commonly used in practical building-integrated photovoltaic (BIPV) applications.

What are double glass PV panels?

The double glass PV panels are simplified as five layers composite structure, including cover glass, ethylene-vinylacetate (EVA), silicon solar cells, EVA and back glass. Since it’s too thin to make any influence, the battery layer is assumed as a continuous layer.

Learn More

- South America Double Glass Module Price Per Watt

- Bandar Seri Begawan double glass photovoltaic module manufacturer

- 9BB high efficiency photovoltaic double glass module

- Double glass module installation and fixation

- Tanzania double glass photovoltaic module manufacturer

- Huawei photovoltaic carport double glass module

- Double glass module manufacturer in Kuwait City

- EU double glass module manufacturer

- Australian double glass photovoltaic module manufacturer

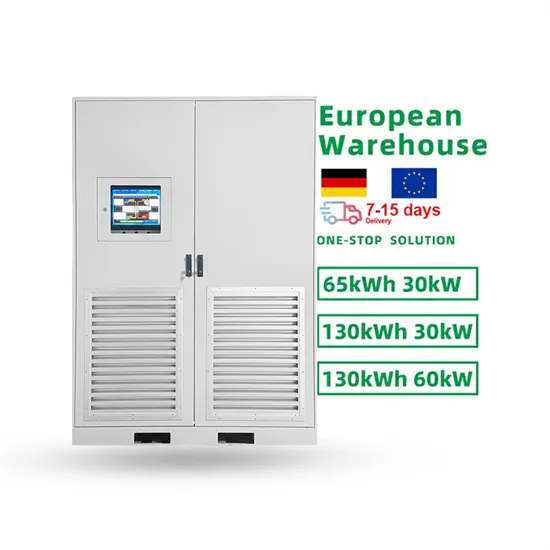

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.