Comparatively Assessing different Shapes of Lithium-ion Battery Cells

Jan 1, 2017 · Different shapes of lithium-ion batteries (LIB) are competing as energy storages for the automobile application. The shapes can be divided into cylindrical and prismatic, whereas

The Production Process of Cylindrical Lithium

Mar 8, 2025 · In conclusion, the production process of cylindrical lithium - battery packs is a complex and highly - regulated process that requires precision, expertise, and advanced

Manufacturing cost comparison of tabless vs. standard

Jan 30, 2024 · The introduction of the tabless electrode design for lithium-ion battery cells by Tesla in 2020 and its successful industrialisation for the 2022 Model Y marked a significant

Comparison between cylindrical and prismatic lithium-ion cell

Feb 1, 2017 · The relative size and age of the US electric vehicle market means that a few vehicles are able to drive market-wide trends in the battery chemistries and cell formats on the

Manufacturing of tabless cylindrical lithium-ion cells:

Sep 15, 2024 · The authors thank cell manufacturer BAK Battery for providing important insight and participating in valuable scientific discussion about all aspects of manufacturing for

Development perspectives for lithium-ion battery cell

Dec 5, 2022 · As one central result, the market has witnessed a wide variety of manufacturer- and user-specific cell formats in the past. Standard formats for cylindrical cells were established

Cylindrical Cell Manufacturing

Jun 20, 2025 · Below is a comprehensive guide to the manufacturing process for cylindrical cells, including key steps, equipment, challenges, and future trends. What Are Cylindrical Cells?

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · Furthermore, we present and discuss production technologies for the format and design flexible production of Li-ion cylindrical battery cells. Thereby, we focus on jelly roll

Everything about Cylindrical Batteries, the Power

May 29, 2024 · All eyes of global finished car manufacturers and battery makers are on the 46-series, the new standard of cylindrical batteries. In response, LG

The Production Process of Cylindrical Lithium

Mar 8, 2025 · Uncover the detailed production process of cylindrical lithium - battery packs. Learn about key steps like cell selection, grouping, module assembly, BMS integration, and more.

Cost modeling for the GWh-scale production of modern lithium

Nov 3, 2024 · Battery production cost models are critical for evaluating the cost competitiveness of different cell geometries, chemistries, and production processes.

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Currently, the manufacturing of LIBs still needs to go through slurry mixing, coating, drying, calendering, slitting, vacuum drying, jelly roll fabrication (stacking for pouch cells and

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Lithium-ion Cylindrical Cell Manufacturing Process

Jul 25, 2023 · In this article, we will describe the production process of lithium-ion cylindrical batteries in detail. 1. Lithium-ion Battery Material Preparation. The

Cylindrical Lithium Battery Production Process | JCT Machinery

JCT Machinery : The production process of cylindrical lithium battery involves multiple key links, each of which must be operated precisely to ensure the stability, long life and high energy

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Cylindrical Cell manufacturing line

Apr 11, 2025 · What is a Cylindrical Cell Manufacturing Line? A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries.

Lithium Ion Battery Assembly Process and Line: Cylindrical vs

Aug 20, 2024 · Prismatic cells, known for their rectangular shape, are favored in applications requiring space efficiency and higher energy density, such as electric vehicles and large-scale

Cylindrical Lithium Battery Production Line: Fully Automated

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process

Cylindrical Cell Manufacturing

Jun 20, 2025 · Cylindrical cell manufacturing is a highly specialized and technically advanced process that involves the production of lithiumion batteries housed in cylindrical metal cans.

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

6 FAQs about [Cylindrical lithium battery cell production]

How are cylindrical lithium-ion cells produced?

The production of cylindrical lithium-ion cells involves several meticulously controlled steps to ensure quality and performance. The primary stages include electrode preparation, cell assembly, electrolyte filling, formation, and testing. 1. Electrode Preparation

What is a cylindrical lithium-ion cell?

Cylindrical lithium-ion cells are integral to powering a vast array of devices, from smartphones to electric vehicles. Understanding the assembly process of these cells not only demystifies the technology but also highlights the precision and innovation involved in their creation.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

How jelly rolls are made for Li-ion battery cells?

After electrolyte filling, the cell is sealed. Jelly rolls for cylindrical Li-ion battery cells differ in two basic designs: (1) With tabs (Design A and Design B) and tabless (Design C and Design D). The main process in jelly roll production is the winding process.

Learn More

- Small cylindrical single cell lithium battery

- Cylindrical lithium battery cell factory

- Huawei cylindrical lithium battery cell

- Syria cylindrical lithium iron phosphate battery

- Colombia cylindrical lithium battery sales

- What is the largest size of cylindrical lithium battery in Afghanistan

- Elliptical cylindrical lithium battery

- Cylindrical 12v lithium battery

- Ecuador nca cylindrical lithium battery

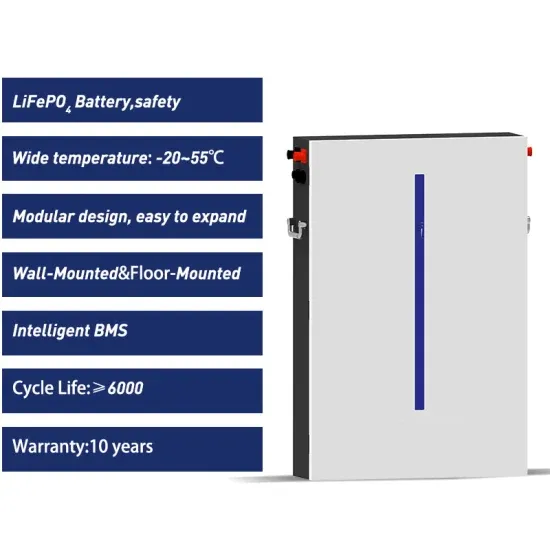

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.