Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Economic cost and technical efficiency analysis of thermal

Sep 15, 2022 · Abstract In this paper, the thermal management (THMA) of a lithium-ion battery pack (BPA) and economic analysis of the cost of cooling electricity consumption are studied

Homogenized characterization of cylindrical Li‐ion

Dec 1, 2023 · Taking samples out of the original jellyroll wounding or compressing cell assembly in its cylindrical coordinates are two possibilities for measuring the homogenized lateral

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Novel hybrid thermal management system for cylindrical lithium

Aug 15, 2025 · Abstract Heat dissipation issues, particularly at high discharge rates, constrain the safe use of Li-ion batteries, making effective thermal management essential. This study

Numerical investigation of thermal management of lithium ion battery

Jan 30, 2024 · Energy (2023) L. Li Comparative study of thermal management systems with different cooling structures for cylindrical battery modules: side-cooling vs. terminal-cooling

Numerical investigation of nanofluid flow in thermal

Apr 20, 2024 · Abstract The present study numerically studies a rectangular battery pack (BTP) with three rows and seven columns of cylindrical lithium-ion batteries placed in an elliptical

Combining an active method and a passive method in cooling lithium

May 1, 2022 · Abstract In this paper, a gentle air flow is simulated among cylindrical lithium-ion battery (LIIB) cells using COMSOL software. A circular PCM compartment is placed around

Dynamic impact response of lithium-ion batteries,

Previous studies by Sahraei and co-workers have focused on characterization of large deformation and failure in pouch, cylindrical, and elliptical lithium-ion battery cells and

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Elliptical lithium‐ion batteries: Transverse and axial

Supporting: 1, Mentioning: 11 - Use of lithium‐ion batteries in mobile applications requires understanding of their response in the case of an impact and mechanical damage. Several

Dynamic impact response of lithium-ion batteries,

In this research, a methodology is proposed for predicting the material response and failure patterns of lithium-ion batteries subjected to high impact based on the experimental results at

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

Homogenized characterization of cylindrical Li‐ion battery

Dec 17, 2021 · In the present study, a novel and highly accurate characterization method is developed to extract homogenized mechanical properties of cylindrical lithium-ion batteries

The Clay-like Mechanics Model of Cylindrical Lithium-Ion Battery

Jun 1, 2016 · A simple load case was chosen to reveal the essential mechanics properties of cylindrical lithium-ion battery and it was found that its mechanics characteristic is clay-like,

Numerical investigation on cooling cylindrical lithium-ion-battery

Sep 1, 2023 · The fluid cooling system can manage the peak battery temperature and the temperature differential among batteries within a tolerable range, therefore increasing the

Elliptical lithium‐ion batteries: Transverse and

Mar 27, 2019 · A, Constitutive block of lithium‐ion batteries; B, an elliptical cell before testing; C, compression between flat plates in the transverse direction;

Simultaneous application of active and passive methods in

Jun 1, 2022 · Simultaneous application of active and passive methods in cooling of a cylindrical lithium-ion battery by changing the size of the elliptical cavity filled with nano phase change

Elliptical lithium

Jun 13, 2021 · The constitutive block of all lithium- ion batteries is electrode layers coated on thin aluminum or copper foils separated by a porous polymeric layer, called a separator. In pouch

Simultaneous application of active and passive methods in

Jun 1, 2022 · For the active method, a forced and laminar airflow is used in the battery pack. For the passive one, phase change material (PCM) is employed around all battery cells placed in

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · This paper is a comprehensive numerical investigation of the optimization of thermal management systems of lithium-ion batteries (LIBs) through the synergistic integration

Homogenized characterization of cylindrical Li-ion battery

Dec 17, 2021 · Homogenization and finding the constitutive model of jellyroll in cylindrical lithium-ion batteries can be challenging because of their form factor. Taking samples out of the

Simultaneous application of active and passive methods in

Jun 1, 2022 · Request PDF | Simultaneous application of active and passive methods in cooling of a cylindrical lithium-ion battery by changing the size of the elliptical cavity filled with nano

6 FAQs about [Elliptical cylindrical lithium battery]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

Learn More

- Lithium battery 3 6v cylindrical double

- Dili Large Cylindrical Lithium Battery

- Capacity cylindrical lithium battery

- Minsk cylindrical lithium battery customization factory

- Venezuelan cylindrical lithium battery milliwatt normal

- Madrid cylindrical lithium battery

- Cylindrical lithium iron phosphate battery has high cost performance

- How much is the Montenegro cylindrical lithium battery

- Cylindrical lithium battery plate

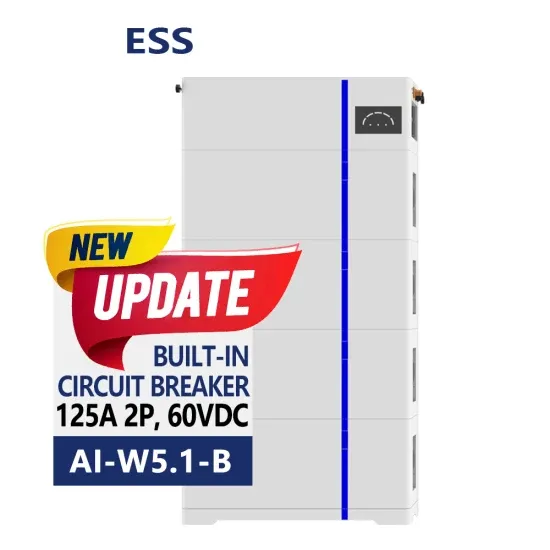

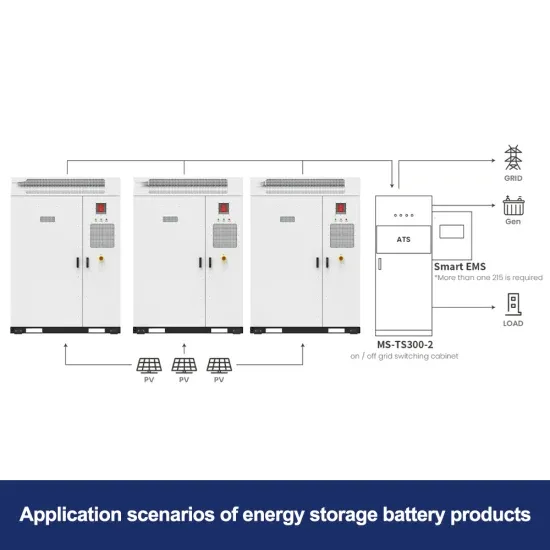

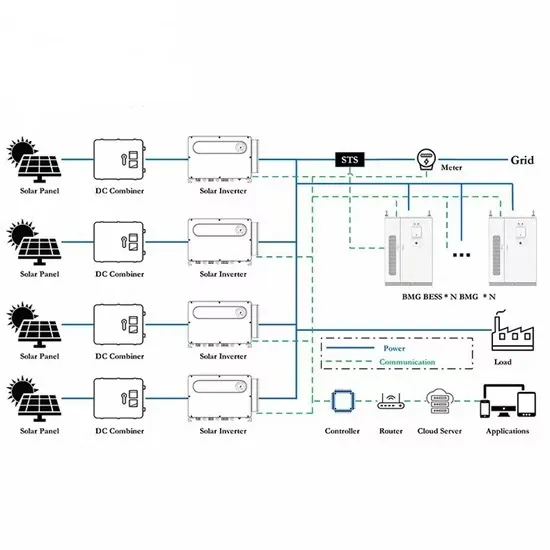

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.