Global Cylindrical NMC & NCA Battery Market 2025 by

Cylindrical NMC/NCA Battery is a Cylindrical lithium ion Battery made up of NMC or NCA anode materials. China"s policy on lithium-ion batteries mainly focuses on lithium-ion batteries.

Identification of waste lithium-ion battery cell chemistry for

Feb 15, 2025 · This study investigated the applicability of a non-destructive battery diagnostic methods, namely incremental capacity analysis (ICA), for identifying EOL lithium-ion battery

Evaluation of the laminar burning velocity of various battery

Aug 1, 2025 · Three commercial cylindrical cells—Lithium Nickel Cobalt Aluminium Oxide (NCA), Lithium Iron Phosphate (LFP), and Lithium Nickel Manganese Cobalt Oxide (NMC)—were

NCA battery characteristics and comparison

2 days ago · NCA battery is also a lithium-ion battery, compared with NCM, its chemical composition is changed from manganese to aluminum, which is characterized by a longer life.

Aging mechanisms of cylindrical NCA/Si-graphite battery

Dec 1, 2024 · The advancement of EVs imposes higher demands on the energy density of lithium-ion batteries, driving the development and utilization of new high-energy electrode materials.

Li-Ion NCA/NMC Cylindrical Hard Case Cells Market 2022

Feb 14, 2024 · Less cells in battery pack – Saving assembly cost. Cylindrical li-ion cell manufacturing capacity is around 850 Million per month during 2021 and will reach 3.2 Billion

Extreme fast charging performance of 4680 lithium-ion batteries

Lithium-ion batteries are the most common type used in battery electric vehicles. Recently, researchers have focused on enabling extreme fast charging (XFC) in lithium-ion batteries,

Comparison between 18650 Lithium-ion Cells of

Nov 14, 2023 · Figure 1 illustrated the cylindrical lithium-ion cells, 18650, considered in this study (a) Lithium Nickel Cobalt Aluminium Oxide (NCA), (b) Lithium Titanate Oxide (LTO) and (c)

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Li-Ion NCA/NMC Cylindrical Hard Case Cells Market 2022

Feb 14, 2024 · Cylindrical Cells Manufacturing Capacity Forecast Cylindrical li-ion cell manufacturing capacity is around 850 Million per month during 2021 and will reach 3.2 Billion

Thermal Investigation of Cylindrical Lithium-ion Batteries

Thermal investigation of cylindrical lithium-ion batteries of different chemistry and shape factors (18650 NMC and 21700 NCA) is conducted for different charging/ discharging rates (0.5 C, 1

Investigation of the Electrochemical and Thermal

Sep 14, 2023 · Utilization of lithium-ion batteries in electric vehicles has shown considerable potential and benefits for tackling these issues. The effective management of battery

A review on the thermal runaway behaviors of non-cylindrical

However, the thermal hazard data among non-cylindrical lithium-ion batteries scattered due to differences in capacity, shape, and battery chemistry. This study provides a review of the

Cell geometry influences on the vibration performance of lithium

Feb 15, 2025 · Lithium-ion batteries are rechargeable energy storage systems in which lithium ions travel between negative and positive electrodes during charging and discharging [1]. In

Comparison on Thermal Runaway and Critical

Nov 15, 2024 · LiFePO4 (LFP) ≫ 26650 LFP > 14500 non-LFP > 18650 LFP > 14500 LFP. Among all types of cylindrical lithium-ion batteries, the 21700 exhibits the worst consequence, which is

Comparison on Thermal Runaway and Critical

Mar 3, 2025 · The thermal hazard results of commercial cylindrical lithium-ion batteries (LIBs) of different sizes from international laboratories are reviewed

Understanding calendar aging degradation in cylindrical lithium

Jan 1, 2025 · 1. Introduction Lithium-ion batteries have become essential components of modern technology for powering a wide range of devices. However, despite the increased performance

Lithium-ion Battery Cell Types, LFP, NMC Cells

Jul 13, 2022 · EV batteries can be filled with cells in different kinds and shapes. This article will explore the lithium-ion battery cells used inside electric

Thermal Investigation of Cylindrical Lithium-ion Batteries for

Nov 28, 2022 · This class of batteries, relative to its predecessors such as the 18650 or NCA-21700 cylindrical batteries, offers a more voluminous energy density while maintaining a

Dynamic mechanical integrity of cylindrical lithium-ion battery

Jul 1, 2015 · Further, by considering the strain rate and inertia effect of the battery structural and material, the dynamic mechanical behavior of lithium-ion battery is investigated. Different

Aging mechanisms of cylindrical NCA/Si-graphite battery

Dec 1, 2024 · To investigate the impact of actual operating conditions of electric vehicles on the performance degradation of lithium-ion batteries, four different degradation paths were

Comparison on Thermal Runaway and Critical

Nov 15, 2024 · This review on the critical characteristics of cylindrical batteries under thermal failure and thermal abuse provides a reference for solving intrinsic safety issues for lithium-ion

6 FAQs about [Ecuador nca cylindrical lithium battery]

Who makes NCA batteries?

NCA battery was developed by Tesla and Panasonic in 2019. However, due to high technical barriers, most car manufacturers have not put it into use. NCA batteries are currently installed on Tesla electric vehicles. In September 2020, Tesla released its new 4680 large cylindrical battery at the Battery Day event.

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

Will China be able to make ternary lithium batteries?

However, almost all large battery companies are actively researching and developing NCA. It can be expected that China will be able to break through technical barriers and mass-produce NCA batteries in the future. NCM and NCA battery will simultaneously become the main structure of ternary lithium battery.

What is the voltage of NCA batteries?

The voltage of the currently available NCA comprising batteries is between 3.6 V-4.0 V, at 3.6 V-3.7V of nominal voltage. They are also utilized in electric appliances and electric cars, x≈ 0,8. In 2019, LiNi0,84Co0,12Al0,04O2 is the version of the oxides that were in usage. NCA’s Manufacturer

What does NCA stand for ternary lithium cathode?

NCA refers to the English abbreviation of nickel (NI), cobalt (CO), and aluminum (Al) in the ternary lithium cathode material. ● NI——Increase and increase the volumetric energy density of the material. ● CO—stabilizes the layered structure of the material while enhancing the cycle and rate performance of the material.

What are lithium ion batteries?

Lithium-ion batteries are rechargeable batteries where the lithium-ions move from the negative to the positive electrode via the processes of charging and discharging. These batteries are highly efficient in performing their tasks and authenticating the industries and markets, in which they are working.

Learn More

- How much is the Montenegro cylindrical lithium battery

- Cylindrical lithium battery diameter 25 height 65

- Minsk cylindrical lithium battery customization factory

- Lithium battery 3 6v cylindrical double

- Huawei Tokyo cylindrical lithium battery

- Is the Wellington cylindrical lithium battery useful

- Madrid cylindrical lithium battery

- Cylindrical lithium iron phosphate battery has high cost performance

- Cylindrical lithium battery plate

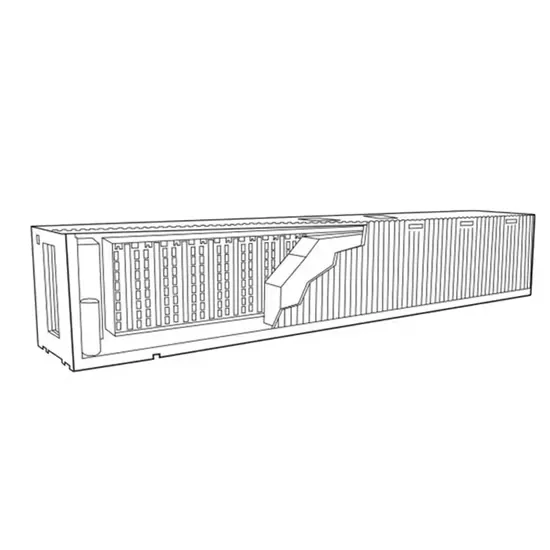

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.