Glassy materials for Silicon-based solar panels: Present and

Nov 1, 2023 · Here, we review the current research to create environmentally friendly glasses and to add new features to the cover glass used in silicon solar panels, such as anti-reflection, self

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

CRYSTALLINE SILICON PHOTOVOLTAIC GLASS

2 days ago · Crystalline silicon photovoltaic glass is recognized for its superior energy output, yielding more energy than amorphous silicon glass under direct sunlight. This technology is

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · These photovoltaic modules use high-efficiency monocrystalline silicon cells (the cells are made of a single crystal of very high-purity silicon) to

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · The findings affirm the feasibility and cost-effectiveness of silicon wafer recovery from damaged silicon solar panels, emphasizing the importance of adaptable recycling

Co-recovery of Ag and Si from PV cell panels: Directional

Jan 19, 2025 · This work proposes a refining process for optimizing the separation and recovery of silver and silicon using PV glass assisted directional solidification technology, in order to

Crystalline PV Glass VS. Amorphous Silicon PV

Oct 28, 2022 · Crystalline silicon photovoltaic glass is a kind of silicon glass that can generate electricity. "In crystalline silicon PV cells, solar cells are typically

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

A novel method for refining photovoltaic waste silicon

Jul 1, 2025 · However, photovoltaic waste silicon powder (PWSP) and photovoltaic waste glass (PWG), as the inevitable by-products during the producing and working course of solar cells,

A comprehensive review on the recycling technology of silicon

Apr 5, 2024 · Reduced Environmental Impact: Incorporating reclaimed glass, silicon, and metals into the manufacturing of silicon photovoltaic (PV) panels has been noted to alleviate the

Comprehensive recycling and utilization of photovoltaic

Jul 15, 2023 · Large amounts of silicon kerf waste (SKW) and photovoltaic (PV) glass waste are being generated as the PV industry grows. At present, independent appr

Low Temperature Solar Cell Encapsulation with Novel

Mar 29, 2023 · This type of material is used as an alternative to pre-shaped aluminum or silicone foam spacers in the fabrication of insulated glass, but also as edge material for thin-film PV

PV Glass: The Future of Solar Energy and Building Design

Technologically advanced, PV glass is engineered with a thin layer of silicon solar cells that capture light and convert it into usable energy. This glass is designed to be durable, often with

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

Life cycle assessment of recycling waste crystalline silicon

Nov 15, 2024 · Abstract Crystalline silicon photovoltaic (PV) modules that have reached the end of their service life, if not effectively recycled, result in the loss of valuable resources such as

Solar glass/Photovoltaic glass classification

Aug 27, 2019 · Solar glass/Photovoltaic glass classification As new energy,solar glass is now widely used in building curtain wall, photovoltaic roof, sunshade,

Crystalline Silicon Photovoltaic Modules, Crystalline Silicon

Crystalline photovoltaic glass refers to solar glass that incorporates traditional crystalline silicon photovoltaic (PV) technology. Unlike thin-film technologies like CdTe or CIGS, crystalline

6 FAQs about [Photovoltaic silicon glass]

What is Photovoltaic Glass?

Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern architecture. This innovative material transforms ordinary windows into power-generating assets through building-integrated photovoltaics, marking a significant breakthrough in renewable energy integration.

What is crystalline silicon photovoltaics?

Crystalline silicon photovoltaics is the most widely used photovoltaic technology. Crystalline silicon photovoltaics are modules built using crystalline silicon solar cells (c-Si). These have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium.

What are the different types of Photovoltaic Glass Technologies?

To meet specific requirements, we offer two advanced photovoltaic (PV) glass technologies: amorphous silicon and crystalline silicon, both fully customizable. Crystalline silicon photovoltaic glass excels with the highest power output per square meter.

What type of glass is used for solar panels?

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable, weather resistant photovoltaic modules. The glass type that can be used for this technology is a low iron float glass such as Pilkington Optiwhite™.

Why is Solar Photovoltaic Glass so popular?

With global attention on environmental protection and energy efficiency steadily rising, the demand for solar photovoltaic glass in both commercial and residential construction sectors has significantly increased. The desire to reduce energy costs and carbon footprint has driven the widespread adoption of solar photovoltaic glass.

What materials are used in photovoltaic technology?

The active photovoltaic layer, responsible for converting solar energy into electricity, is composed of semiconductor materials. In crystalline silicon-based PV glass, this layer contains ultra-thin silicon wafers, while thin-film technologies utilize materials such as amorphous silicon, cadmium telluride, or copper indium gallium selenide (CIGS).

Learn More

- The relationship between silicon sulfide and photovoltaic glass

- Photovoltaic silicon glass

- Photovoltaic glass back frame

- How much does 2mm photovoltaic glass cost

- Abu Dhabi non-standard photovoltaic glass component research and development

- Solar photovoltaic transparent glass

- Making monocrystalline silicon photovoltaic panels

- Comparison of photovoltaic glass transmittance 20 and 40

- Installation of photovoltaic curtain wall with power generation glass

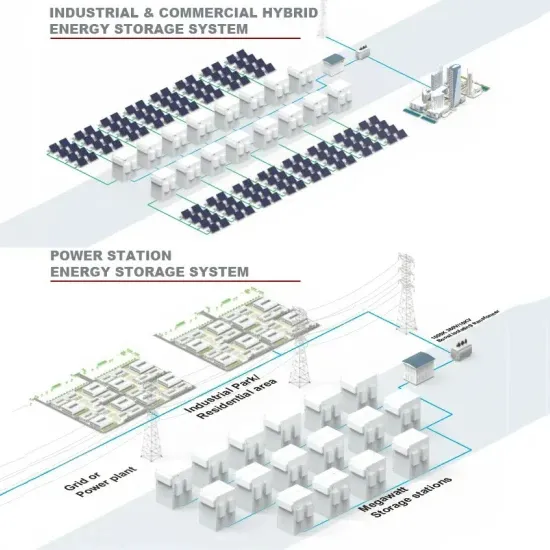

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.