Measurement and prediction of angle-dependent optical

Jul 1, 2001 · Request PDF | Measurement and prediction of angle-dependent optical properties of coated glass products: Results of an inter-laboratory comparison of spectral transmittance and

Experimental investigation and annual overall performance comparison

Dec 1, 2021 · A comprehensive comparison is presented to reveal the difference between the hollow PV vacuum glazing, PV vacuum glazing and hollow PV glazing by the analysis of

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is available for free download in the

BS EN 62805-2:2017-光伏(PV)玻璃的测量方法-国家标准馆

BS EN 62805-2:2017 specifies methods for measuring the transmittance and reflectance of glass used in photovoltaic (PV) modules and provides instructions on how to calculate the effective

Solar photovoltaic panels with 40 light transmittance

For a photovoltaic glass transmittance of 40%, the highest photovoltaic power generation efficiency is 63%, while the average efficiency is 35.3%. This has significant Therefore, this

The Abrasion of Photovoltaic Glass: A Comparison of the

Nov 15, 2019 · Dust deposition density, reduced transmittance, the ratio of reduced transmittance between bare glass surfaces and coatings, and PV efficiency reduction were used to

Smart solar windows for an adaptive future: A

The MTH achieves a solar transmittance modulation from 77 % (20 °C) to 16 % (40 °C), with a modulation amplitude of 61 %. Guan et al. [100] fabricated a tough thermoresponsive

Spectral transmission of solar radiation by plastic and glass

Jul 1, 2020 · In 2006, Tuchinda et al. [9] reviewed the factors affecting glass UV protective properties, such as glass type, colour, interleaves and coating. They found that clear glass

Daylighting performance assessment of a split louver with

Nov 1, 2023 · A daylight model is developed in this study to characterise the daylighting performance of the proposed PV glazing-integrated split louver system with different slat

Investigation on the daylight and overall energy

Dec 15, 2018 · In order to ensure good indoor daylighting quality, an optimal configuration for double-skin STPV facades consisted of an outer layer of PV glass with a transmittance of

Impact of Different Types of Dust on Solar Glass

May 27, 2025 · In the transmittance case, light that reaches the rear side at an angle greater than the critical angle of total internal reflection, 40°, is guided out of the glass sample and does not

Transmittance improvement and photocatalyst performance

Aug 1, 2025 · Abstract The transmittance and surface condition of photovoltaic cover glass determine the energy conversion efficiency of specific solar cells modulus. In this study, TiO 2

Fractal textured glass surface for enhanced performance and

Oct 15, 2022 · Photovoltaic (PV) modules face significant performance loss due to the reflection of solar radiation and dust accumulation on the PV glass cover. Micro- and nanoscale texturing

A comparison of 15 polymers for application in photovoltaic modules in

Apr 1, 2012 · In order to find alternative materials for common glass and EVA laminates, we evaluated 15 polymers, some with glass fiber reinforcement (GFR), of which we assume they

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · Optimized results of low-E semi-transparent amorphous-silicon photovoltaic glass applied on the façade show that the spatial daylight autonomy is increased to 82% with

Photovoltaic glass transmittance and power generation rate

Compared with conventional PV glass which has transmissivity greater than 90% at 400–1200 nm, the PMF we designed has equivalent transmissivity between 410 and 1200 nm and high

Comparison of energy performance between PV double

Dec 12, 2023 · Abstract Building-integrated photovoltaic (BIPV) windows provide the benefits of generating electricity, reducing building cooling and heating energy consumption, and

Photovoltaic panel transmittance selection criteria

This paper reports the use of a combination of numerical calculations and experimental work to establish the optimum photovoltaic transmittance (Tpv) and durability of the quarter wave, the

Polymer multilayer film with excellent UV-resistance & high

Aug 15, 2021 · The choice of polymer material as photovoltaic (PV) module front cover is important to realize high optical transparency and high UV-resistance. We have successfully

Impact of Different Types of Dust on Solar Glass

May 27, 2025 · Our study used dust samples from Morocco, Qatar, and two from Thailand. The data analysis indicates that three dusts exhibit a comparable slope in soiling loss relative to

Study on BC module packaging loss: The influence of photovoltaic glass

Photovoltaic glass with high transmittance helps more light energy reach the cell, thereby improving the photoelectric conversion efficiency of photovoltaic modules. Due to its excellent

Optimized design and comparative analysis of double-glazed photovoltaic

Dec 15, 2024 · This study investigates the daylighting performance and energy efficiency optimization strategies of double-glazed photovoltaic windows (DS-STPV) in cold regions of

The Abrasion of Photovoltaic Glass: A Comparison of the

Feb 10, 2020 · Hemispherical transmittance and haze as a function of the number of dry-brush cycles for J (no coating) glass. Increase in haze for n>10000 ⇒ glass (no coating) can be

Dust impact on photovoltaic modules: Global data,

Oct 1, 2024 · This study explores the influence of dust on optical properties such as transmittance, absorptance, and emissivity of photovoltaic (PV) modules using over 300 experimental

Impact of Different Types of Dust on Solar Glass Transmittance and PV

May 26, 2025 · Our study used dust samples from Morocco, Qatar, and two from Thailand. The data analysis indicates that three dusts exhibit a comparable slope in soiling loss relative to

BS EN 62805-2:2017-光伏(PV)玻璃的测量方法-国家标准馆

BS EN 62805-2:2017规定了测量材料透射率和反射率的方法 用于光伏(PV)组件的玻璃,并提供如何计算 这种玻璃的有效半球透射率和反射率。 本文件适用于光伏组件中使用的光伏玻璃,

Method for measuring photovoltaic (PV) glass

IEC 62805-2:2017 specifies methods for measuring the transmittance and reflectance of glass used in photovoltaic (PV) modules and provides instructions on how to calculate the effective

Impact of Different Types of Dust on Solar Glass

Jun 3, 2025 · In addition, the optical transmittance of the glass sam - ples was reduced by 75%–5% because of dust deposits ranging from 2.9 to 24.3mg/cm2. The transmission and

Optimizing semi-transparent BIPV windows for balanced

Feb 1, 2025 · For photovoltaic glass with very low transmittance, it can lead to a loss of outdoor views and negatively affect the indoor environment. In practice, the selected semi-transparent

Impact of Different Types of Dust on Solar Glass Transmittance and PV

May 26, 2025 · The accumulation of dust on photovoltaic modules in arid and semiarid regions results in significant energy losses. However, evaluating these losses in different locations is

Overall energy assessment of semi-transparent photovoltaic

Apr 1, 2019 · PV insulated glass unit (IGU) is an alternative for STPV window applications. This paper presents a comprehensive assessment on overall energy performance of PV-IGUs with

Comparison of energy performance between PV double skin facades and PV

May 15, 2017 · The results show that the average energy saving potential of the PV-DSF and the PV-IGU are 28.4% and 30%, respectively, compared to the commonly used insulating glass

An optimal and comparison study on daylight and

Mar 11, 2021 · An optimal con guration for double-skin STPV facades consisted of an outer fi layer of PV glass with a transmittance of 30%, and an inner layer of Low-E glass was offered for an

Photovoltaic panels with a light transmittance of 40

Article Photovoltaic windows cut energy use and CO2 emissions by 40% in highly glazed buildings Vincent M. Wheeler,2,3 Janghyun Kim,1 Tom Daligault,1 Bryan A. Rosales,1 The

6 FAQs about [Comparison of photovoltaic glass transmittance 20 and 40]

What is the transmittance of PV glass?

The transmittance of PV glass, which is the ratio of the light transmitted through it to the incident light varies with different PV coverage rates (area proportion of photovoltaic cells) and different materials of PV modules.

Does low PV glass transmittance reduce solar heat gain?

Lowered PV glass transmittance and the realization of natural ventilation through the DSF structure would both contribute to the reduction of solar heat gain into the room context.

How does glass transmittance affect the power generation efficiency?

This will in turn influence the PV module temperature and thus the power generation efficiency . The glass transmittance acts as an important factor affecting both the thermo-optical properties of the STPV unit itself and the overall performance of the combined system (STPV-DSF).

Does PV transmittance affect temperature distribution of STPV-DSFS?

The outer skin with PV glass always absorbed more heat than the clear glass, resulting in a maximum temperature increase of about 4 °C. Temperature profiles of STPV-DSFs with glass transmittance of 20% and 40% presented similar trends, indicating no significant influence of the PV transmittance on the temperature distributions of STPV-DSFs.

What is the transmittance of uncoated solar glass?

The transmittance of conventional uncoated solar glass at a vertical incidence of light is approximately 91%. The front reflects around 4%, around 4% on the back, and 1% absorption. In addition, there are double reflections within the glass, which is in the order of 0.2%.

Does dust affect the transmittance of soiled glass?

One approach is to consider the light-scattering effects of dust when measuring the transmittance of soiled glass samples and the differing light paths in glass samples and PV modules. The transmittance of conventional uncoated solar glass at a vertical incidence of light is approximately 91%.

Learn More

- Comparison of photovoltaic power generation with power generation glass

- Photovoltaic glass light transmittance

- Photovoltaic glass and hit battery

- Photovoltaic panel glass clamp

- Is photovoltaic power generation made of glass

- Manama Photovoltaic Multi-span Glass Greenhouse

- Photovoltaic glass solar power generation

- Japanese light-transmitting series photovoltaic power generation glass design

- Photovoltaic glass Photovoltaic glass

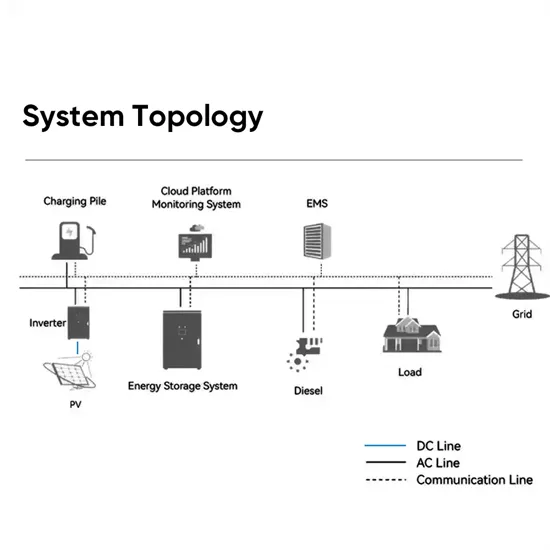

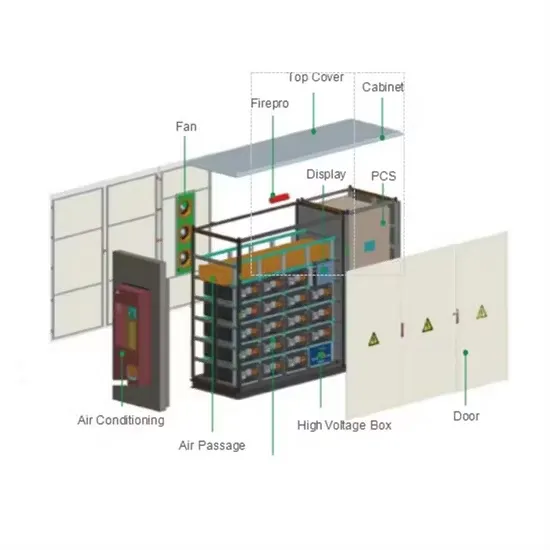

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.