Evaluation for the Light Transmission Property of Solar Glass

Sep 1, 2013 · Download Citation | Evaluation for the Light Transmission Property of Solar Glass | Transmittance is the key factor to the quality of solar glass. At present visible light

Solar Glass: What Is It & What Is Its Role In Solar

Jul 22, 2021 · The deep processing process is usually to coat and toughen the original glass. The purpose of the coating is to improve the light transmittance

Dust impact on photovoltaic modules: Global data,

Oct 1, 2024 · It is crucial to understand how dust influences the optical properties of PV modules in terms of PV glass transmittance, absorbance and reflected light as well as emitting heat

Texturized glass in the application of architectural

Oct 1, 2024 · The most commonly used glass in photovoltaics is low-iron soda-lime glass, which protects solar cells from atmospheric factors, provides strength, and determines light

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Random subwavelength structures on glass to improve photovoltaic

Oct 1, 2022 · The global spectral transmittance and reflectance of structured glass samples have been measured and compared to a flat glass and a commercial photovoltaic glass with AR

Examination of an Optical Transmittance Test for

Sep 26, 2013 · Optical transmittance is a key performance characteristic for photovoltaic (PV) encapsulation materials. The discoloration of encapsulation (and corresponding reduction in

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency. Advances in glass compositions,

Photovoltaic glass panel transmittance standard

solar glass? High solar radiance transmittance. The type of solar glass directly influences the amou t of solar radiation that is being transmitted efficiency of the solar panel, the

外文版计划

Mar 7, 2025 · 本标准已于2018年提升为国际标准ISO/TS 18178:2018 Glass in building—Laminated solar photovoltaic glass for use in buildings,并被英国、丹麦等采纳为本国标准。 目前GB/T

Requirements for Light Transmittance of Solar Panels

Dec 6, 2023 · The light transmittance requirements for solar panels depend on several factors, including the type of solar technology used and the specific application of the solar panels.

How to use Transmittance meter to measure Photovoltaic Glass light

What is the light transmittance of photovoltaic glass? The light transmittance of photovoltaic glass refers to the proportion of light passing through the glass in the visible spectrum range. If the

Transmittance improvement and photocatalyst performance

Aug 1, 2025 · Therefore, how to improve the transmittance and environmental stability of PV glass have become critical issues for PV glass. Multi-functional thin film coating on PV glass,

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

ISO 23237:2023 建筑用玻璃 建筑用层压太阳能光伏玻璃

Jul 3, 2025 · Glass in building – Laminated solar photovoltaic glass for use in buildings – Light transmittance measurement method 首页 标准 ISO 23237:2023 标准全文 ISO 23237:2023 预

Transmittance improvement and photocatalyst performance

Aug 1, 2025 · The results indicate the excellent anti-pollution, low temperature tolerance, and wear resistance performance of SiO 2 -TiO 2 thin film coated PV glass. The coated glass can

How to create a high value green building with light

Mar 24, 2025 · Apple''s headquarters adopts a light-transmitting photovoltaic glass curtain wall with a light transmission rate of 40%. The façade of the building presents a minimalist metallic

A review of advanced architectural glazing technologies for

Aug 3, 2022 · Efficient management of solar radiation through architectural glazing is a key strategy for achieving a comfortable indoor environment with minimum energy consumption.

6 FAQs about [Photovoltaic glass light transmittance]

What is the difference between visible transmittance and visible reflectance?

Visible transmittance (τv) and visible reflectance (ρv) refer to the ratio of the beam of visible light vertically incident on a glass surface to the incident beam of transmitted light or reflected light.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

Can spectral converters be integrated into PV glass?

A standardized model is presented for evaluating the efficiency of spectral converters integrated into PV glass, systematically assessing spectral absorption and emission properties, current drop and current gain, material stability, and integration feasibility.

How do specialized coatings improve light transmission to photovoltaic cells?

Propagation of light waves through (a) multilayers and (b) single glass layer (n s>nir). minimizing reflection effects. be better solved via computational methods. energy systems. These specialized coatings and materials are designed to minimize dirt accumulation and enhance light transmission to photovoltaic cells. The develop-

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

How can we improve the efficiency of photovoltaic (PSC) systems?

In this manner, we can facilitate a more effective integration of PSCs into our daily lives. The accumulation of pollution and any kinds of contamination on the glass cover of the solar cell affects the efficiency of the photovoltaic (PV) systems.

Learn More

- Light Energy Technology mainly deals in photovoltaic glass

- Comparison of photovoltaic glass transmittance 20 and 40

- Photovoltaic glass production in East Africa

- How many pieces of photovoltaic glass are enough

- Photovoltaic glass and hit battery

- Is Kigali photovoltaic glass scarce

- Is there a photovoltaic glass factory in Borno

- Honiara photovoltaic glass manufacturer

- The main function of photovoltaic glass

Industrial & Commercial Energy Storage Market Growth

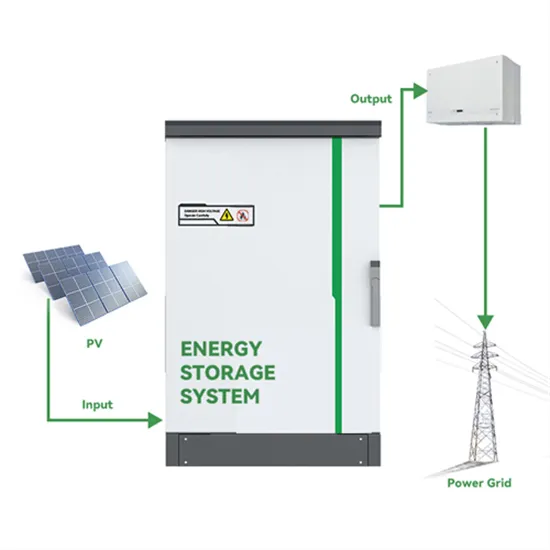

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.