How do power plants work? | How do we make

Apr 20, 2025 · A power plant''s job is to release this chemical energy as heat, use the heat to drive a spinning machine called a turbine, and then use the turbine

PERFORMANCE ANALYSIS OF DIESEL ENGINE POWER

Dec 17, 2023 · Power generating stations in which diesel engines are used as the prime movers for electric generators are known as diesel power plants [3]. The diesel burns inside the

Which is better, a generator or a power station?

Jul 14, 2024 · A power station, often referred to as a portable power station or battery generator, utilizes stored electrical energy from batteries to provide power. These devices are typically

Diesel Power Stations | Könner & Söhnen Blog in

Apr 5, 2023 · Diesel power stations (DPS) are an effective, high-capacity solution for reliable power supply in the absence of the mains supply or when the

What is better, a power station or a generator?

Aug 13, 2025 · When considering portable energy solutions, many people wonder whether a power station or a generator is the better option. A power station, often a battery-powered

How Do Electric Generators Generate Electricity?

Sep 4, 2018 · An electric generator is a machine that uses an engine to generate electricity. This blog will explain how power generators work and their main

POWER STATION ENGINEERING

3 days ago · Generators are considered as the main equipment for the electric power generation. It generates electricity when it is driven by a prime mover. On the basis of the types of prime

Portable Generator Vs Power Station: Which Is Best for You

Dec 7, 2024 · Portable generators and power stations both supply external energy in case of outages, but they differ in terms of ease of use, cost, and portability.

6 FAQs about [Power station engine and generator power]

How does a generator work in a power station?

At the center of nearly all power stations is a generator, a rotating machine that converts mechanical energy into electrical energy by creating relative motion between a magnetic field and a conductor. The energy source harnessed to turn the generator varies widely.

What is the difference between a fuel-powered generator and a power station?

Unlike fuel-powered generators, power stations’ runtime and wattage is tied to their battery capacity. Power stations usually top off at 3,500 watts as opposed to the 20,000-watt ceiling of fuel-powered generators. The run time on one charge is also usually shorter than the run time you’ll get from one full tank of a fuel powered generator.

What is a portable power station?

Portable power stations, also called gasless generators, store electrical power in an internal battery that must be recharged.

What is a power plant?

A power station (also referred to as generating station or power plant) is an industrial facility for the generation of electric power. Power plant is also used to refer to the engine in ships, aircraft and other large vehicles.

Is a power station better than a generator?

While that’s larger than a power bank, power stations are much more portable than generators (and they’re quiet as there’s no continuously running engine). Plus, they don’t burn fuel, so you can use them safely indoors. And if you’re into renewables, some models even have solar-powered charging capabilities.

How many Watts Does a power station use?

Power stations usually top off at 3,500 watts as opposed to the 20,000-watt ceiling of fuel-powered generators. The run time on one charge is also usually shorter than the run time you’ll get from one full tank of a fuel powered generator. (Of note: Power station runtimes are measured in watt hours (Wh).

Learn More

- Hargeisa mobile power station generator manufacturer

- Hydroelectric power station generator

- Power station generator set transformation

- Malta LNG power station generator

- BESS a generator for the Sino-European rainproof power station

- The model of the generator in a power station is sf120

- Photovoltaic power station generator impeller

- How many kilowatts does the generator set of Kuala Lumpur Power Station have

- Tuvalu Rainproof Power Station Generator BESS

Industrial & Commercial Energy Storage Market Growth

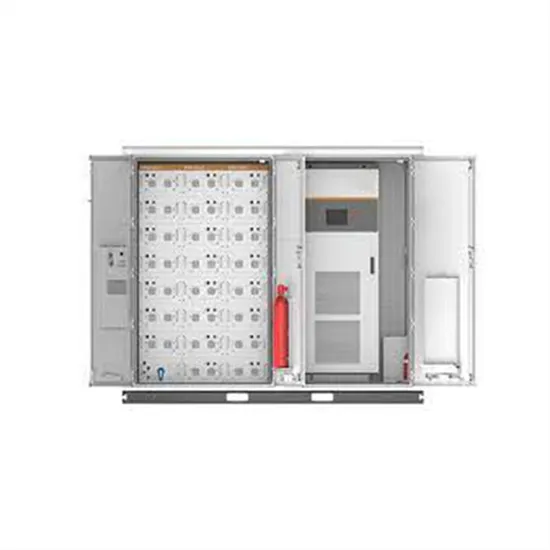

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.