Natural Gas Power Generation, Combined Cycle Gas

Aug 25, 2016 · Tender documents have been posted by the Public Gas Corporation of Cyprus (DEFA) in search for a counterparty that will supply and install a floating storage and

Malta energy storage power station project

FREDERICTON, NB and CAMBRIDGE, MA - October 28th, 2021 - Malta Inc., a leading developer of innovative pumped heat energy storage technology, and NB Power, the largest utility in the

Delimara power station

Aug 19, 2025 · Delimara power station is an operating power station of at least 547-megawatts (MW) in Marsaxlokk Bay, South Eastern, Malta. Loading map... Unit-level coordinates (WGS

(PDF) From Heavy Fuel Oil to Liquified Natural Gas: Electricity

This study focuses on the shift in the source for electricity generation in Malta. This is done by comparing the emissions from two power stations (Marsa; MPS and Delimara; DPS) which ran

INFORMATION TO THE PUBLIC

May 18, 2023 · The Delimara Power Station falls within the remit of the "Control of Major Accident Hazards (COMAH) Regulations, Legal Notice 179/2015 and it is classified as an upper tier

(PDF) From Heavy Fuel Oil to Liquified Natural Gas: Electricity

In Malta several fuels have been traditionally used to generate electricity, such as coal fired systems and the recent natural gas power station. Malta first acquired electricity in 1882 by

Gas-fired – the five biggest natural gas power

Apr 14, 2014 · The power plant generated 39.85 billion kWh of electricity in 2013. Futtsu power station, Japan – 5,040MW The 5,040MW Futtsu liquefied natural

Malta''s Gas and Power Project: A Visionary Leap Towards

May 9, 2025 · In 2013, Malta embarked on a transformative journey in energy infrastructure with the Malta Gas and Power project—a pioneering initiative that set the stage for the nation''s

Natural Gas Power Generation, Combined Cycle Gas

Aug 25, 2016 · Malta''s D3 power plant, formerly known as the BWSC plant, has faced repeated delays and full conversion to gas is now understood to take up to 12 months. Only four

Profiling five of the world''s biggest gas-fired

Nov 5, 2019 · In case of coal power stations, reaching full capacity takes hours. Here we profile five of the world''s biggest gas-fired power stations. Five of the

6 FAQs about [Malta LNG power station generator]

Where is natural gas piped in Enemalta?

D3 & D4 – The natural gas is piped towards Enemalta’s D3 unit and also to D4, a new combined cycle power plant, and the fourth component of the ElectroGas Malta installation.

What is ElectroGas Malta?

Construction began with the clearing of the old HFO (Heavy Fuel Oil) power plant and regasification sites in the winter of 2016. Facilities were finalised in 2017. The ElectroGas Malta Facilities consist of four main parts: A Floating Storage Unit – An LNG cargo vessel which has been converted specifically for this project.

When did ElectroGas Malta start construction?

Design of the facilities began in late 2015 after the conclusion of the Enemalta tender process. Construction began with the clearing of the old HFO (Heavy Fuel Oil) power plant and regasification sites in the winter of 2016. Facilities were finalised in 2017. The ElectroGas Malta Facilities consist of four main parts:

When did Enemalta start building LNG-to-power facilities at Delimara?

Construction of LNG-to-power facilities at Delimara formed a core requirement of the contract awarded by Enemalta to EGM in 2013. [Read More] Design of the facilities began in late 2015 after the conclusion of the Enemalta tender process.

What is the Delimara Power Station complex at Marsaxlokk?

The Delimara Power Station complex at Marsaxlokk includes the four electricity generation plants that we dispatch on a daily basis to provide the electrical energy required by our customers in Malta and Gozo. The total combined nominal installed capacity of this power station is 537.8 MW.

How many MW does Enemalta have?

The total combined nominal installed capacity of this power station is 537.8 MW. Enemalta plc’s energy mix also includes several grid-connected renewable energy sources as well as the 200 MW Malta-Italy Interconnector .

Learn More

- Qatar LNG power station generator

- Generator set of Rongliubao Power Station

- Hydroelectric power station generator

- Samoa Rainproof Power Station Generator BESS

- Ulaanbaatar Mobile Power Station Generator BESS

- Permanent magnet generator power station

- 100kw photovoltaic power station generator

- Kazakhstan mobile power station generator

- Lisbon trailer power station generator manufacturer

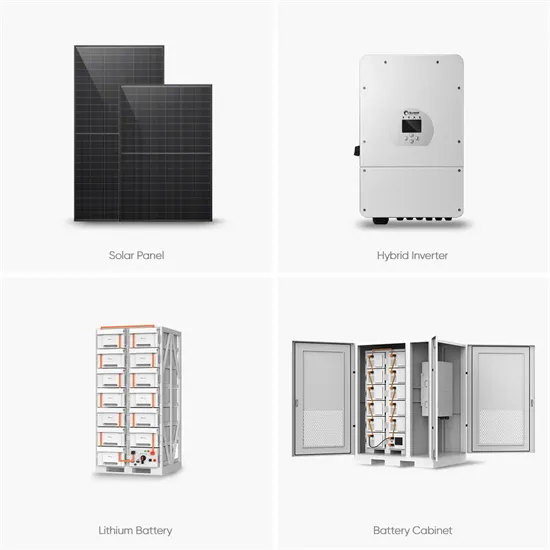

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

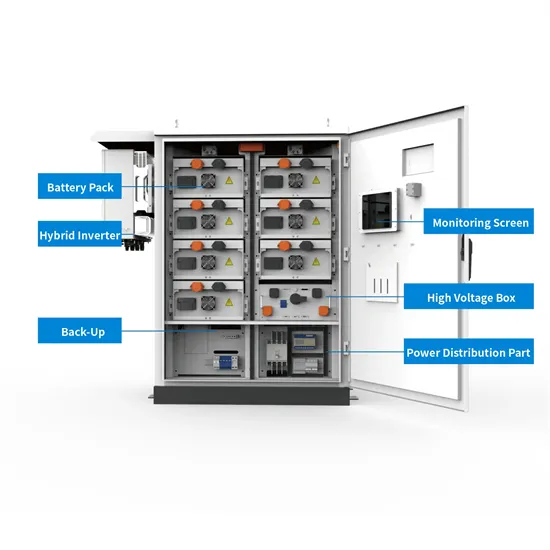

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.