650kw Rainproof Diesel Engine Power Station for All

May 2, 2025 · 650kw Rainproof Diesel Engine Power Station for All Conditions, Find Details and Price about Electric Start Generator Set Diesel Engine Generator Set from 650kw Rainproof

Presentación de PowerPoint

Sep 30, 2021 · BESS Advantages Offering large number of application opportunies in addition to black start capabilities. Fast response (<1 sec) of power supply to the grid until the gas turbine

Long-term Power Supply Battery Solar Station Utility Scale BESS

With the operation for 20 years, we get abundant technology accumulation and rich industry experience. Based on new generation technology, Comler Power producers generators are

Backup power for Europe

Jan 9, 2025 · To gain a comprehensive understanding of the evolving landscape of BESS in Europe, RaboResearch is publishing a series of articles on the market attractiveness for BESS

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · The US electricity grid frequency is 60Hz, while the European grid frequency is 50Hz. • What will charge the BESS? Solar photovoltaic (PV), wind, grid, diesel generators are

Battery energy storage system (BESS) integration into power

4 days ago · BESS can help enable increased electrification of oil and gas facilities by improving onsite power generation efficiency and reliability and supporting the integration of intermittent

On BESS Capacity Optimization of Hybrid Coal-Fired Generator and BESS

Apr 4, 2025 · Integrating battery energy storage systems (BESS) into a coal-fired generator can enhance power systems'' secondary frequency regulation capability. To this end, this paper

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

What Is BESS? a Comprehensive Overview of Battery Energy

Jun 11, 2025 · BESS, short for Battery Energy Storage System, is an advanced energy storage technology solution widely adopted in the renewable energy sector. Within the industry, it is

Battery energy storage system (BESS) integration into power

4 days ago · Primary power source support: in remote oil and gas operations where diesel or gas generators are the primary power source, BESS can store excess energy and provide backup

Battery Energy Storage System

5 days ago · Battery Energy Storage System Diesel generators are commonly used for additional power supply at construction sites today. As a low carbon alternative, Battery Energy Storage

Battery Energy Storage Systems (BESS) as a Key

Jan 30, 2025 · ss European countries, especially in the ancillary services market. The most efficient way to trade BESS and produc-tion-oriented VPPs (with co-located batteries) involves

BESS 101: Understanding Battery Energy Storage

4 days ago · A Battery Energy Storage System (BESS) is a technology that stores energy generated from various sources, such as solar or wind power, in large

On BESS Capacity Optimization of Hybrid Coal-Fired Generator and BESS

Apr 4, 2025 · To obtain a cost-effective BESS investment, this paper develops a new sizing method, which optimizes the BESS capacity by simulating the operation of the hybrid coal

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

BATTERY ENERGY STORAGE SYSTEMS (BESS)

Jul 8, 2024 · The compact power blocks allow the connection of power cables at input or output of BESS sub-systems control panels such as PCS, central and solar inverters. They combine

6 FAQs about [BESS a generator for the Sino-European rainproof power station]

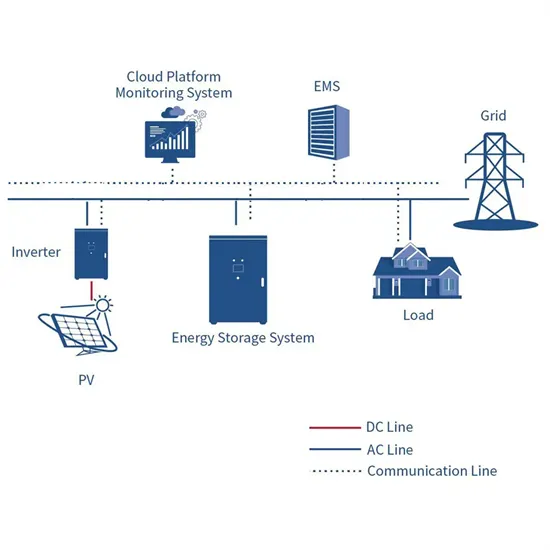

What is a Bess inverter?

a bidirectional link for energy flow. In BESS architecture, the inverter is typically positioned between the battery storage unit and the grid or loads, serving as an intermed ary for power conversion and control. The inverter uses various measurements—including voltage, current, frequency, and temperature—to

What is a Bess battery & market integration?

hich currently are the bestBESS and Market Integration2.1 BESS are r chargeable batteries designed to store energy from various sources. The system then releases the stored electricity back into the grid when it is economically advantageous, such as during peak hours or in response to specific balancing orders from the Distributi

Why do we need a Bess battery optimisation system?

sumption, utilities and independent power producers can reduce the cost of energy they provide.There are several demand drivers for the expansion of BESS capacity, namely the sharp and continuing fall in costs of battery storage technologies, making battery optimisation even more affordable, and the significant drop in lit

What is a Bess sensor & monitoring system?

ansformer. Sensors and Monitoring The BESS and its BMS rely on critical measurements such as state of charge (SOC), battery temperature, voltage and current levels, power output and

What is a Bess plant?

The structure of a BESS plant is conceptually quite simple, with a small number of basic components: Batteries: these are the basic units that make up a BESS. They are the cells where, through electrochemical reactions, the charging and discharging of electricity takes place.

Does a Bess need a cooling system?

The BESS being a temperature-controlled environment, it will most probably need extra cooling if it is in direct sunlight. By avoiding direct sunlight, you will then re- duce the BESS’ own energy consumption. This can be summarized in the table on the follow- ing page:

Learn More

- Samoa Rainproof Power Station Generator BESS

- Tuvalu Rainproof Power Station Generator BESS

- N Djamena Mobile Power Station Generator BESS

- Danish generator communication BESS power station

- Andorra photovoltaic power station generator installation

- The voltage generated by the photovoltaic power station generator

- Polish Communication BESS Power Station

- Palikir Pumped Storage Power Station Generator Manufacturer

- Botswana Communications BESS Power Station Cost

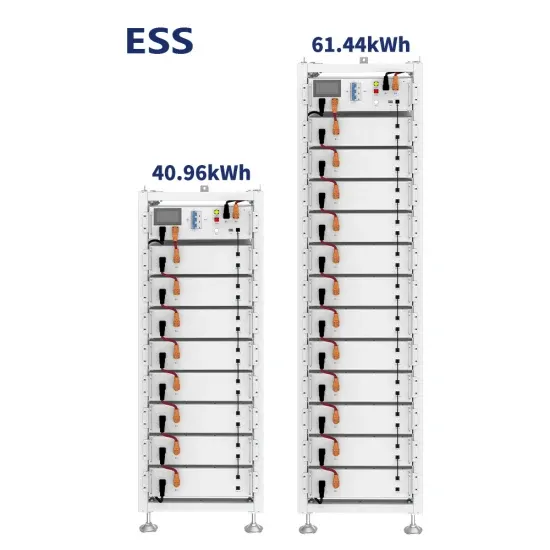

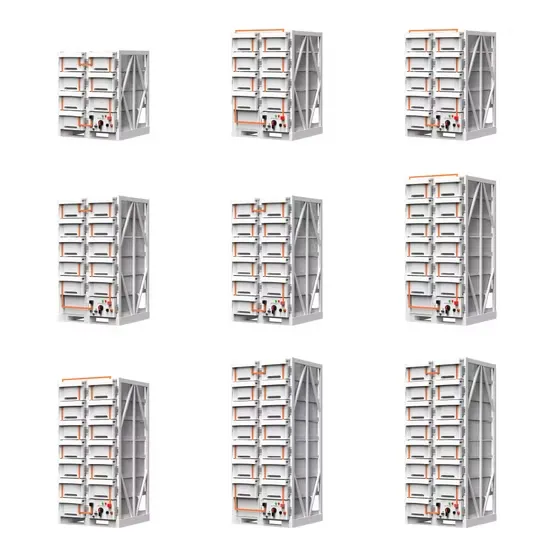

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.