Application of the Singular Spectrum Analysis on

Nov 15, 2022 · This paper discusses an application of the singular spectrum analysis method (SSA) in the context of electroluminescence (EL) images of thin-film photovoltaic (PV)

Recent Advancements in Thin-Film Solar Modules

Jun 9, 2025 · Thin-film solar modules transform the renewable energy landscape with their lightweight design, flexibility, and cost-effective production. Unlike

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition

Thin-Film Applications in Different Fields | SpringerLink

Jan 3, 2025 · This chapter describes the application of thin films in various fields. We look at the applications of thin film in sensors, actuators, and solar cells and the many types of sensors in

Modelling of flexible thin-film modules for building and

Jul 1, 2018 · In this work we present a simulation of performance of curved thin-film modules for building and product integrated photovoltaic applications. Flexibi

Thin-Film Solar: Applications And Efficiency

Apr 30, 2025 · Unlike traditional silicon-based panels, thin-film solar cells are built by depositing one or more thin layers of photovoltaic material onto a substrate,

Building integrated photovoltaics in practical use: The 5GSOLAR thin

Dec 16, 2024 · The antimuonium-based PV technology (Sb 2 (S,Se) 3 is an alternative to all those propositions. This new material, developed in the Laboratory for Thin Film Energy Materials at

The Applications of Thin Films in Solar Energy

Jun 27, 2023 · Thin-film solar cells contain thin layers of photovoltaic materials to break electrons free from atoms, creating electricity. The invention of thin-film

Photovoltaic Technology: The Case for Thin-Film

Jul 30, 1999 · The advantages and limitations of photovoltaic solar modules for energy generation are reviewed with their operation principles and physical

[2109.04048] Application of the Singular Spectrum Analysis

Sep 9, 2021 · This paper discusses an application of the singular spectrum analysis method (SSA) in the context of electroluminescence (EL) images of thin-film photovoltaic (PV)

Thin-Film Technologies for Sustainable Building

Dec 18, 2024 · This study investigates the incorporation of thin-film photovoltaic (TFPV) technologies in building-integrated photovoltaics (BIPV) and their

Thin Film Photovoltaics

Jan 1, 2018 · Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

Practical application of building integrated photovoltaic (BIPV) system

May 1, 2011 · An analysis has been carried out on the first practical application in Korea of the design and installation of building integrated photovoltaic (BIPV) modules on the windows

Modelling of flexible thin-film modules for building and product

Jul 1, 2018 · In this work we present a simulation of performance of curved thin-film modules for building and product integrated photovoltaic applications. Flexibility of design and possibility of

6 FAQs about [Application of photovoltaic thin film modules]

What is a thin-film solar panel?

Thin-film cells convert solar energy into electricity through the photovoltaic effect. The micron-thick layers that contain photon-absorbing materials form thin-film solar cells that rest on a durable, resilient substrate. The endurance of thin-film solar panels sets them apart from the other competitors. Thin-Film Solar Panel Applications

What are thin-film photovoltaic (PV) modules?

Thin-film photovoltaic (PV) modules are among the main alternatives to silicon modules in commercial solar energy systems. Thin-film technologies account for a small but growing share of the global solar market and are expected to grow at a compound annual growth rate of 23% from 2020-2025.

What are the applications of thin films in solar panels?

Solar modules Another important application of thin films in PV is the antireflection coating (ARC) on the surface of solar glass where the light first reaches the solar panels. Currently, single-layer antireflection coated solar glass has a dominant market share of 95% compared to glass with other coatings or no coating, for Si PV modules .

How do thin-film solar cells work?

The basic principle behind thin-film solar cells is similar to traditional solar cells – they convert sunlight into electricity through the photovoltaic effect. Here’s a simplified breakdown of the process: Light absorption: When sunlight hits the thin-film solar cell, the photovoltaic material absorbs the photons.

Can thin-film solar cells be used in space?

Lightweight solar: The low weight of thin-film solar cells makes them attractive for space applications, and research is ongoing to develop radiation-resistant and efficient thin-film cells for satellites and other spacecraft. The properties of thin-film solar cells open up a range of applications beyond traditional solar panels.

What are the advantages of thin-film solar technology?

Thin-film solar technology offers several unique advantages that make it an exciting option for certain applications: Flexibility: Unlike rigid silicon panels, many thin-film solar cells can be made flexible. This allows for integration into curved surfaces, portable devices, and even clothing.

Learn More

- Chromium telluride thin film photovoltaic modules

- PVDF film for solar photovoltaic modules

- Amman thin film solar system application

- Rooftop photovoltaic panel application

- Huawei photovoltaic glass extended application

- Libya thin film photovoltaic panel manufacturer

- Differences between single-sided and double-sided photovoltaic modules

- Total exports of photovoltaic modules

- Doha monocrystalline silicon single glass photovoltaic modules

Industrial & Commercial Energy Storage Market Growth

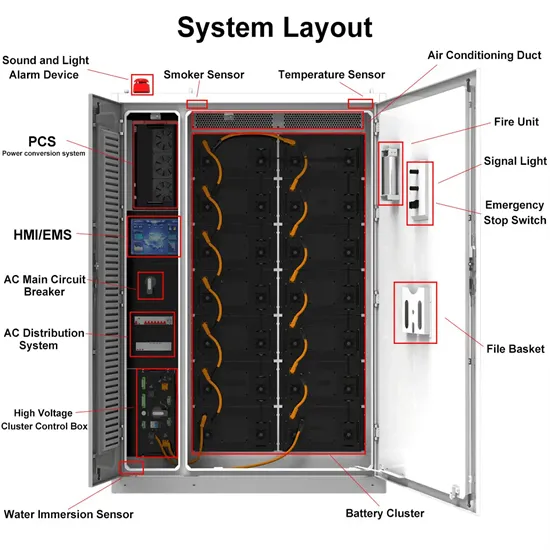

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.