How Many Lithium-Ion Cells Are Needed for a 48V Battery?

Dec 9, 2023 · To create a 48V battery using lithium-ion cells, you typically need 13 cells connected in series, assuming each cell has a nominal voltage of 3.7V. This configuration

Power Tool Battery Charging: Do''s, Don''ts & Pro

Apr 3, 2025 · Each battery type has unique charging requirements to maximize efficiency and lifespan. Here''s how to charge them correctly: 1. Charging NiCd

How To Balance A Lithium Batteries and Cells

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

How Many Cells in a Lithium Battery Pack? A Complete

Mar 14, 2025 · Lithium batteries use multiple cells. For example, a lithium-ion battery has 3 cells for 11.1 volts, 4 cells for 14.8 volts, or 10 cells for 37 volts. Cells can be arranged in series to

How to Build A Battery Pack From 18650 Cells

Mar 30, 2022 · Lithium-ion is currently the best battery chemistry humanity has. It is the perfect choice when looking to build a battery pack with 18650 cells. In

How to Charge a Lithium-Ion Battery Properly: Step-by-Step

Nov 15, 2024 · Learn how to charge a lithium-ion battery safely and effectively with our guide to best practices, tips, and charging do''s and don''ts.

How To Wire Lithium Batteries In Parallel

Aug 9, 2022 · In this article, we will explain why you would want to wire lithium-ion batteries in parallel, how you wire them in series and how to charge battery

Li-Ion Cells: Charging and Discharging Explained

Jun 12, 2024 · It''s crucial to know how to charge and discharge li-ion cells. This article will provide you with a guide on the principles, currents, voltages, and

How Many Cells Are In A Lithium Battery?

Some rechargeable battery cells actually need to be primed whenever they get their first charge ever. However, with lithium-ion cells and batteries, there is no requirement for such.

How Many Watts Is Required To Charge A Cordless Drill

Jun 17, 2025 · When it comes to charging a cordless drill, the wattage requirements can vary depending on the model and battery capacity. Generally, cordless drills have batteries ranging

How to Charge and When to Charge for Maximum Battery Life

Jul 21, 2025 · Charging lithium-ion batteries at moderate temperatures (15–20 °C) helps you extend battery lifespan. Partial charging, rather than full cycles, can double lithium battery life.

Lithium Battery Basics: A Crash Course

Apr 29, 2021 · The C-rate for charging would require the use to wait while the battery system is charging, and in those applications waiting is not desired. Ok, so now you know the basics of

Helpful Guide to Lithium Batteries in Parallel and

Apr 23, 2024 · Part 1. What are lithium batteries in parallel and series? The voltage and capacity of a single lithium battery cell are limited. In actual use,

How to Charge a Lithium Battery Like a Pro in 2025?

By charging properly, you can stretch a battery''s useful life from, say, 300 cycles to over 1000, depending on chemistry and care. Improve Charging Efficiency: Efficient charging ensures that

Small Battery Charging: Top Tips for Lithium Cells

Mar 25, 2025 · Small battery charging is crucial for maintaining lithium-based power sources'' performance, safety, and longevity. Whether you''re charging a

How many lithium cells in a 24v battery?

Oct 9, 2024 · Understanding Battery Voltage and Cell Configuration A 24V battery system typically consists of multiple lithium cells connected in series. The voltage of a single lithium

Best Way to Charge Lithium Ion Battery for Longer Life

Jul 22, 2025 · The best way to charge lithium ion battery for longer life involves understanding how voltage, temperature, and charge cycles affect performance. Stick to partial charging,

How to Charge Lithium Batteries: Complete Guide to Safe

Jul 30, 2025 · Different lithium battery chemistries require specific charging approaches to maximize performance and safety. For example, lithium cobalt batteries typically charge to 4.2

18650 Battery Pack Calculator

May 28, 2025 · This 18650 battery pack calculator is used to determine the optimal configuration of 18650 lithium-ion cells for a specific power requirement. With a 12V battery pack with 10Ah

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

How Many Cells Are In A Lithium Battery?

Due to electronic equipment like our mobile phones that need to be operated for a long while between charges and at the same time consume power, there is a huge need for batteries with

How Many Lithium Cells Are Needed to Create a 12V Battery

Feb 22, 2025 · How Many Lithium Cells Are Needed to Create a 12V Battery To create a 12V lithium battery, 3-4 lithium cells are typically connected in series. Lithium-ion cells have a

6 FAQs about [How many cells are needed to charge tool lithium batteries]

How many cells are in a lithium ion battery?

Lithium batteries use multiple cells. For example, a lithium-ion battery has 3 cells for 11.1 volts, 4 cells for 14.8 volts, or 10 cells for 37 volts. Cells can be arranged in series to increase voltage or in parallel to boost capacity measured in amp-hours (Ah). This setup meets different energy storage needs.

How does a lithium battery charge?

Different lithium battery chemistries require specific charging approaches to maximize performance and safety. For example, lithium cobalt batteries typically charge to 4.2 volts per cell during the constant voltage phase, requiring precise voltage regulation to prevent damage.

How often should a lithium battery be charged?

For lithium battery packs, avoid charging from 0% to 100% in a single cycle. Instead, keep the state of charge between 30% and 80%. This approach reduces stress on the batteries and aligns with optimal charging practices. Scientific studies and manufacturer guidelines show that frequent full cycles accelerate battery degradation.

How should a lithium battery pack be charged?

It is recommended that lithium battery packs be charged at well-ventilated room temperature or according to the manufacturer’s recommendations. Avoid exposing the battery to extreme temperatures when charging, as this can affect its performance and life.

How to calculate lithium cell count in a battery pack?

To calculate lithium cell count in a battery pack, use the formula: Total Voltage = Number of Cells x Nominal Voltage of Each Cell. 1. Understanding nominal voltage of lithium cells. 2. Identifying required total voltage for the application. 3. Considering parallel connections for capacity. 4.

What is a good charge level for a lithium ion battery?

Avoid charging batteries fully from 0% to 100%; keep charge levels between 20% and 80% to double lithium-ion battery cycle life. Monitor multi-battery systems with a Battery Management System (BMS) to balance cells, prevent overcharging, and reduce maintenance costs. Part 1:How to Charge and When to Charge?

Learn More

- How many strings of lithium batteries are needed for a 48v inverter in New York USA

- How long is the life of American cylindrical lithium batteries

- How many batteries are needed for 1 kilowatt photovoltaic panel

- Lithium batteries are divided into cells and battery packs

- How big a photovoltaic panel should be used to charge a 24v lithium battery

- How many lithium battery packs are needed for 60v

- Can the base station power supply charge lithium batteries

- How many batteries are needed for a 48v inverter

- Abkhazia How long is the life of cylindrical lithium batteries

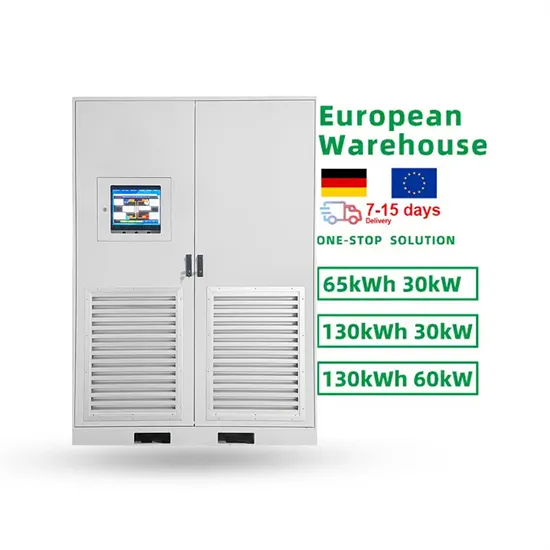

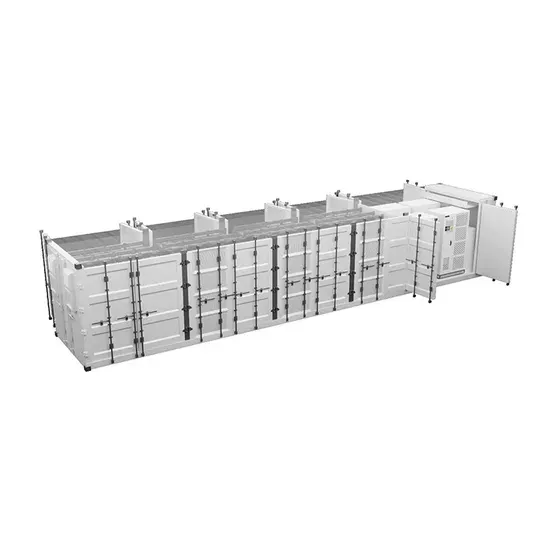

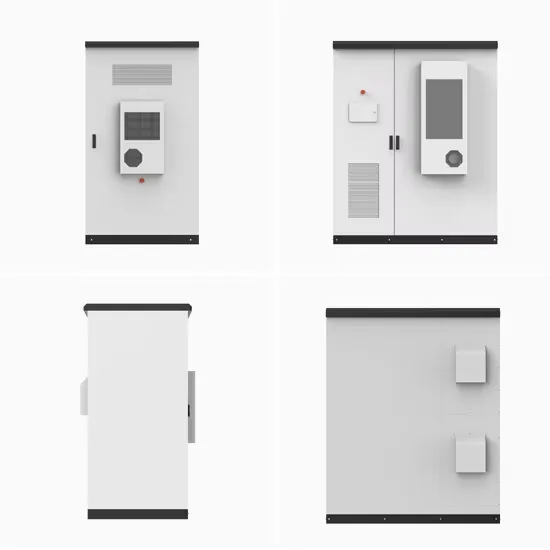

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.