How Are Lithium Batteries Assembled?

May 2, 2025 · Understanding the assembly process of lithium batteries is crucial for ensuring their optimal performance, safety, and reliability. This article explains how lithium batteries are

Cleanrooms for EV Battery Production | ACH

Aug 19, 2025 · For EV battery manufacturing, particularly in the context of lithium-ion battery cells and packs, the following general guidelines might apply: Cell

Lithium Cell Assembly Plant

Feb 21, 2025 · A Lithium Cell Assembly Plant is a specialized facility where lithium-ion cells—the core components of batteries—are manufactured, assembled, and tested. These plants are

Battery 101: The Fundamentals of How a Lithium

Feb 8, 2024 · How does a lithium-ion battery work? It''s a question many battery users have asked themselves when eyeing these high-quality lithium batteries

Lithium-ion batteries explained

Nov 2, 2020 · Lithium-ion batteries – also called Li-ion batteries - are used by millions of people every day. This article looks at what lithium-ion batteries are, gives an evaluation of their

The Intricate Journey of Lithium Battery Assembly: A Detailed

Sep 13, 2024 · The assembly of lithium batteries begins with the preparation of key components: the anode, cathode, separator, and electrolyte. The anode is typically made from graphite,

How Are Lithium Batteries Manufactured? A Step-by-Step

How are lithium batteries made step by step? Lithium batteries are manufactured through a multi-stage process: raw material preparation, electrode production, cell assembly, electrolyte

Meaning of Codes on Lithium Batteries

What Does "V" on a Lithium Battery Mean? V (Voltage): The voltage on a lithium battery indicates its nominal operating voltage. For example, a "3.2V" battery has a nominal voltage of 3.2 volts.

What do the letters mean on this LiPo (or Li Ion) battery?

May 9, 2023 · I''m trying to find a replacement battery for my Bluetooth earphone as they drain out very fast. It is a 3.7 V 55 mAh. Looking through the options I see batteries with better capacity

How Lithium-ion Batteries Work | Department of

Feb 28, 2023 · Lithium-ion batteries power the lives of millions of people each day. From laptops and cell phones to hybrids and electric cars, this technology

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Understanding Battery Labeling: What the

Apr 11, 2025 · Battery labels encode chemistry (e.g., "CR" for lithium), size (like "2032" indicating 20mm diameter x 3.2mm height), voltage, capacity, and

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

6 FAQs about [What does lithium battery assembly mean ]

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

What is lithium ion battery assembly?

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

What is battery assembly?

Battery assembly is the process of assembling parts to create a functioning battery. This involves combining essential components like cells and connectors. Using the right tools and following precise steps is necessary to ensure the battery works properly.

How is a lithium ion battery assembled?

The second stage of the lithium-ion battery assembly process involves assembling the core components. Winding/Stacking: Positive and negative electrodes are alternately layered with separators to form a cell stack. Electrolyte Filling: The electrolyte is carefully injected into the cells to enable ion movement.

What are the three stages of lithium-ion battery assembly?

The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell-making machine workflow.

What is a lithium ion battery?

Composition: Lithium-ion batteries (Li-ion) use lithium compounds as electrolytes, allowing ions to move between the anode and cathode during charging and discharging. Structure: Typically cylindrical or prismatic, manufacturers widely use them in consumer electronics, electric vehicles, and energy storage systems.

Learn More

- What does lithium battery pack gram mean

- What does lithium battery upgrade BMS mean

- What does lithium battery pack consistency mean

- What is the built-in lithium battery pack

- What equipment is needed to make lithium battery pack

- What is a lithium battery energy storage device

- What is the actual life of a 60v lithium iron phosphate battery pack

- Uganda lithium battery pack 72v assembly

- Dakar energy storage lithium battery assembly and production

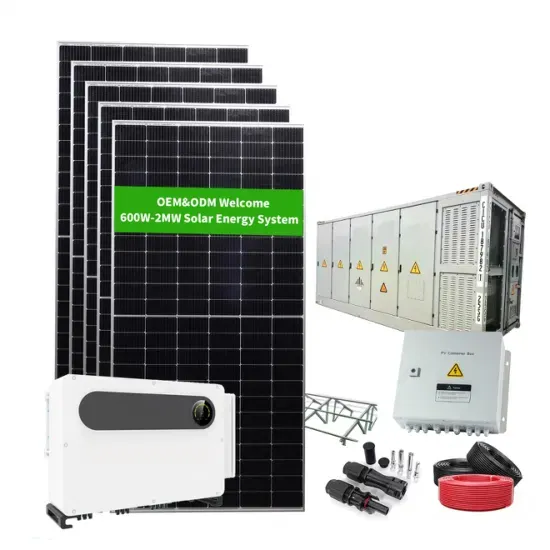

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.