Review of Battery Management Systems (BMS)

Mar 15, 2021 · This report analyzes the details of BMS for electric transportation and large-scale (stationary) energy storage. The analysis includes different aspects of BMS covering testing,

Understanding Battery Management Systems (BMS):

Jan 18, 2025 · A Battery Management System (BMS) plays a crucial role in modern energy storage and electrification applications. It oversees a battery pack''s operational health,

Analysis of energy storage system STS, PCS, ATS, EMS, BMS

The energy storage system consists of several major S components, allowing the entire energy storage system to operate. What are the roles of STS, PCS, ATS, EMS, and BMS in the entire

A review of battery energy storage systems and advanced battery

May 1, 2024 · Battery management systems (BMS) are crucial to the functioning of EVs. An efficient BMS is crucial for enhancing battery performance, encompassing control of charging

Battery Management Systems Topologies: Applications

Oct 11, 2021 · A safe and reliable battery management system (BMS) is a key component of a functional battery storage system. This paper focusses on the hardware requirements

PowerPoint 演示文稿

Mar 1, 2024 · Introduction SmartLi is a battery energy storage system developed by Huawei for UPS, which has the features of safety and reliability, long lifespan, space saving and easy

(PDF) Review of Battery Management Systems

Apr 11, 2021 · Therefore, a safe BMS is the prerequisite for operating an electrical system. This report analyzes the details of BMS for electric transportation and

Typical three-level architecture of energy storage power station BMS

Apr 2, 2025 · In energy storage power stations, BMS usually adopts a three-level architecture to achieve hierarchical management and control from battery module (Pack) - Cluster - Stack.

Battery modular multilevel management (Bm3) converter

Abstract This paper introduces a modular battery system based on an integrated 3-switch inverter topology, referred to as Battery Modular Multilevel Management (BM3) system. The 3-switch

Battery energy storage system connected to a three-phase

Abstract Battery energy storage systems (BESS) employing secondary battery technology may offer the greatest potential for large-scale integration of renewable energy sources (RES), and

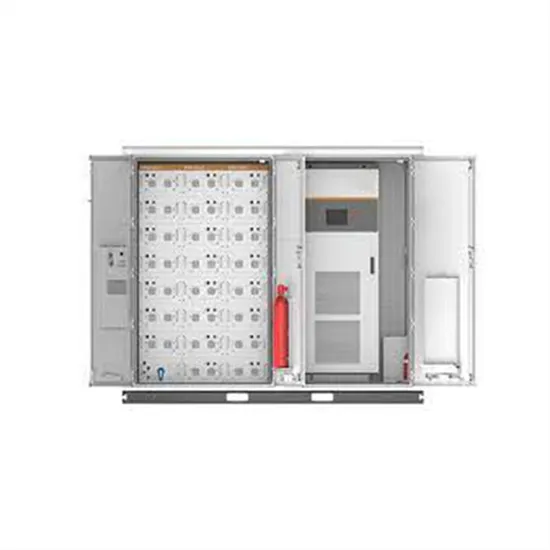

PCS-8813CPB High voltage directly connected energy storage

Integration arrangement of battery/BMS/PCS and filter Standard storage container for primary AC output, separate cooling and fire protection system Cascaded multi-level topology, low IGBT

Residential energy storage systems (ESS) and multi

May 24, 2025 · Infineon''s unique expertise in energy generation, transmission, power conversion, and battery management makes us the perfect partner to advance energy storage solutions

Modular battery management system architecture for

Jan 1, 2023 · In electric vehicles, the utmost is of the operation did the batteries provide energy storage. However, the rechargeable batteries can''t work alone, a BMS is very much needed,

Power converters for battery energy storage systems

Jul 15, 2019 · Abstract Recent works have highlighted the growth of battery energy storage system (BESS) in the electrical system. In the scenario of high penetration level of renewable

Enhancing power quality in electric vehicles and battery energy storage

Feb 28, 2025 · Optimal cell utilization for improved power rating and reliability in a grid-scale three-phase battery energy storage system using hybrid modular multilevel converter topology

Optimization techniques of battery packs using re-configurability

Jun 1, 2019 · It is estimated that by 2030 the world would require nearly 150 GW of battery storage playing a key role in achieving the target of 45 percent power generation from

Understanding the Role of BMS, EMS, and PCS in Battery Energy Storage

Jan 10, 2025 · Discover the critical roles of BMS, EMS, and PCS in Battery Energy Storage Systems (BESS). Learn how these components ensure safety, efficiency, and reliability in

Battery Energy Storage System System Solution Guide

Lithium-ion battery, which is known as the major part of electrochemical storage system, has high power/energy density, high roundtrip efficiency, compact footprint, and flexibility for expansion.

Benefits of multilevel topologies in power-efficient

Feb 8, 2024 · Battery based energy storage systems may be used to create utility independent solar-powered homes or businesses (termed residential or commercial ESS), which are

Technologies for energy storage battery management

Jan 1, 2019 · Based on the battery cluster modes in energy storage systems, a BMS has two kinds of typical structures, i.e., the two-tier topology with the application of battery modular

6 FAQs about [Three-level topology of power storage battery BMs]

What is a safe and reliable battery management system (BMS)?

A safe and reliable battery management system (BMS) is a key component of a functional battery storage system. This paper focusses on the hardware requirements

What is battery management system (BMS)?

This management scheme is known as “battery management system (BMS)”, which is one of the essential units in electrical equipment. BMS reacts with external events, as well with as an internal event. It is used to improve the battery performance with proper safety measures within a system.

Do lithium ion batteries need a BMS system?

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery management system is the brain of the lithium battery and reports the status and health of the battery. Let’s get a better understanding from this article. What is a BMS System?

What is battery management system?

The development of battery management systems is critical to the energy storage system made up of thousands of batteries. Through continuous technical upgrading, other countries have developed relatively mature battery management systems (BMSs), including representative Smart Guard, LGCPI Battery Packs, and BMS 4C.

What are the key technologies for energy storage battery management?

Key technologies for energy storage battery management mainly include SOC (state of charge) estimation, SOH (state of health) estimation, balance management, and protection. SOC is the key index that reflects the real-time residual capacity of energy storage batteries.

What is centralized battery management system architecture?

Centralized battery management system architecture involves integrating all BMS functions into a single unit, typically located in a centralized control room. This approach offers a streamlined and straightforward design, where all components and functionalities are consolidated into a cohesive system. Advantages:

Learn More

- A battery box for an energy storage power station

- Budapest battery exchange energy storage power station

- Battery energy storage on the power generation side

- Power battery and energy storage battery shipments increased

- Bulgaria energy storage battery power station

- Energy storage battery power attenuation measures

- Battery energy storage types for power systems

- Monrovia Power Battery BMS Maintenance

- Power supply error of ordinary energy storage cabinet battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.